Method for preparing Danhong injection, and products thereof

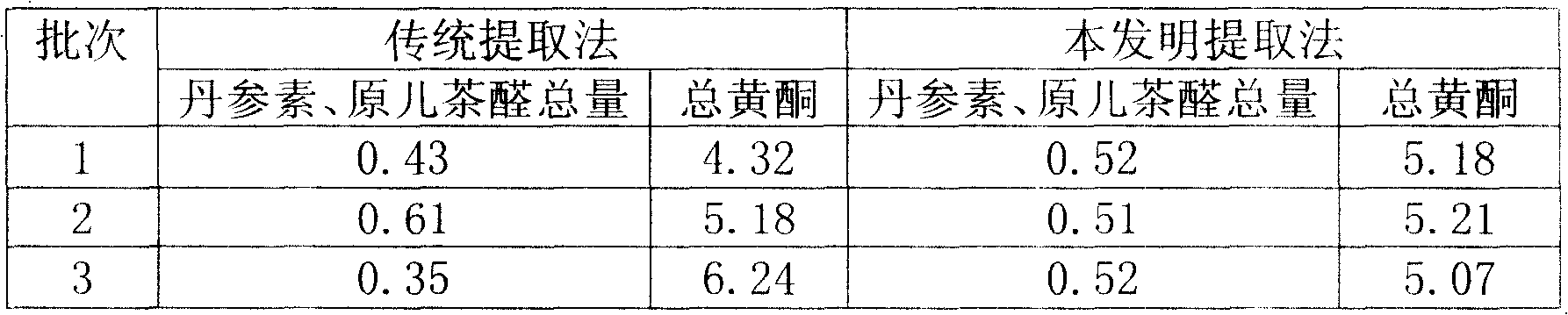

A technology of Danhong injection and injection, which is applied in the preparation of injections and the field of preparation of injections, can solve the problems of human, financial and resource waste, low product qualification rate, and large difference in active ingredient content, and achieve effective ingredient The effect of accurate content, simple quality control and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Take 7.5 kg of Danshen decoction pieces, add 60% ethanol to cover the surface of the decoction pieces, soak in a water bath (70°C) for 1 hour, install a percolator, and then use 70°C warm 60% ethanol to extract by percolation to control the liquid Speed 3ml / min.cm 2 . When the liquid output reaches 75L, stop the percolation, and transfer the percolation liquid to the alcohol recovery tank to recover ethanol. Transfer the liquid medicine liquid to the jacketed pot again, heat until there is no alcohol smell, add an appropriate amount of 5% gelatin solution, stir until no precipitation occurs, filter, and then use the jacketed pot to ventilate the filtrate and concentrate it to a clear liquid with a relative density of 1.10 (65°C). Paste, stop the steam, pass through a 0.45 μm microporous membrane, store the filtrate in a 0-4°C refrigerator for later use, and become the extract I (about 2.5L);

[0019] Determination of active ingredient content in extract solution ...

Embodiment 2

[0035] 1. Take 10 kg of Danshen decoction pieces and put them in a percolation cylinder with interlayer, add 70% ethanol to cover the surface of the medicinal materials, and circulate steam through the interlayer until the liquid temperature in the cylinder reaches 70°C, soak for 1 hour in heat preservation, start percolation, add ethanol, and control percolation The flow rate is 5ml / min.cm 2 , steam and keep warm at 70°C, until the effluent reaches 80L, stop the percolation, transfer the percolation liquid to the alcohol recovery tower to recover ethanol, transfer the water medicine solution to the jacketed pot, add 5% gelatin solution, and stir until no precipitation occurs , after standing for 0.5h, filter, the filtrate is concentrated, to a clear paste with a relative density of 1.10 (65°C), filter with a 0.45 μm microporous membrane, store it in a refrigerator at 0~4°C for subsequent use, and obtain the extract I ( about 3.5L).

[0036] Measure according to the high perf...

Embodiment 3

[0041] 1. Take 7.5 kg of Danshen decoction pieces, add 50% ethanol to cover the surface of the decoction pieces, soak in a water bath (40°C) for 3 hours, install a percolator, and then use 40°C warm 50% ethanol to extract by percolation to control the liquid Speed 1ml / min.cm 2 . When the liquid output reaches 60L, stop the percolation, and transfer the percolation liquid to the alcohol recovery tank to recover ethanol. Transfer the liquid medicine liquid to the jacketed pot again, heat until there is no alcohol smell, add an appropriate amount of 5% gelatin solution, stir until no precipitation occurs, filter, and then use the jacketed pot to ventilate the filtrate and concentrate it to a clear liquid with a relative density of 0.60 (65°C). Paste, stop the steam, pass through a 0.45 μm microporous membrane, and store the filtrate in a 0-4°C refrigerator for later use as the extract I (about 2.0L);

[0042] Measure according to the high performance liquid chromatography of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com