Electrolytic lathe working method

A processing method and electrolytic car technology, applied in electric processing equipment, electrochemical processing equipment, processing working medium, etc., can solve the problems of low efficiency, high cost, low quality of processing surface, etc., and achieve strong localization and good control. , the processing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

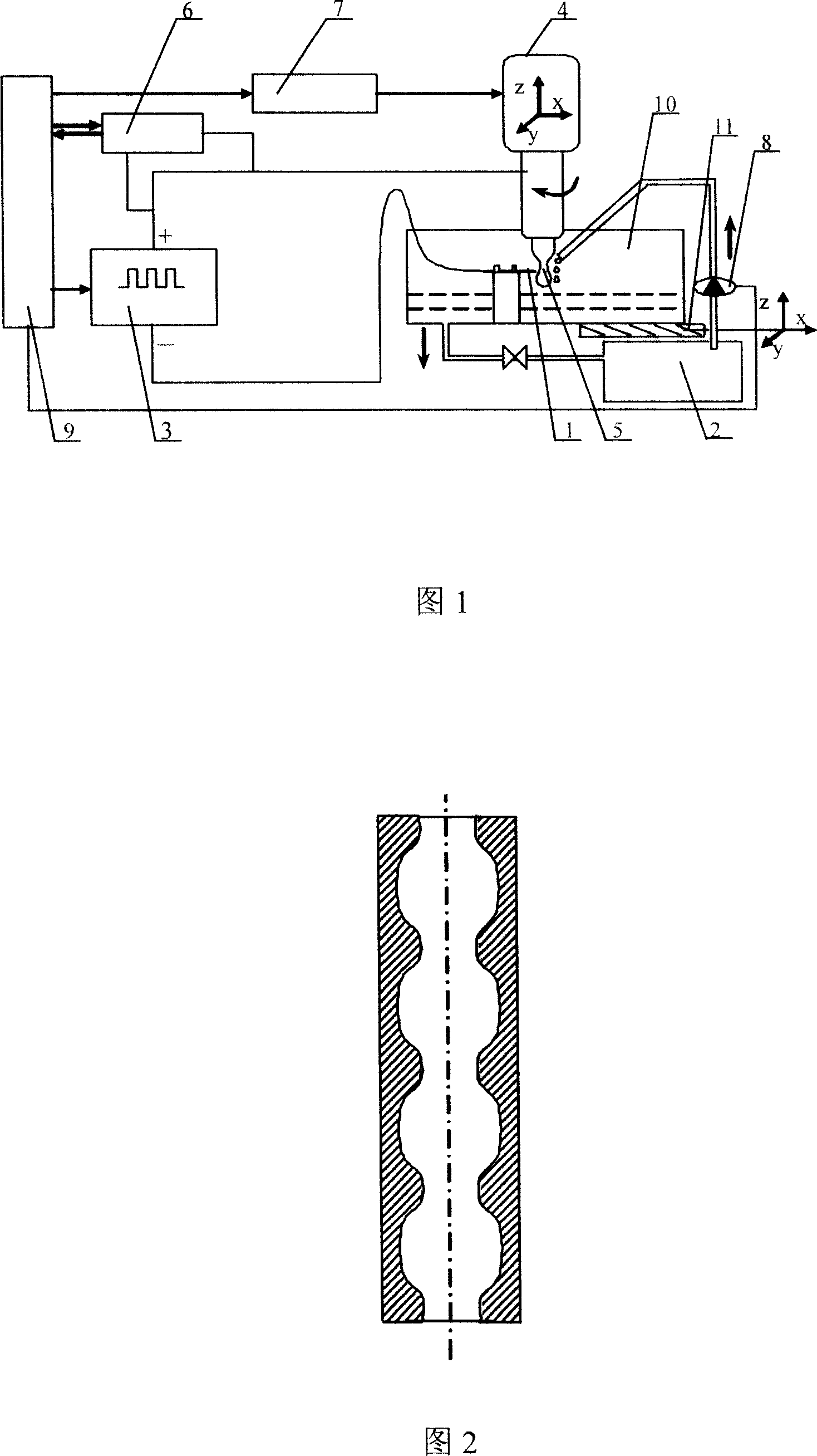

[0027] Below in conjunction with Fig. 1, this implementation mode is specifically described, and this implementation mode includes the following steps

[0028] The tool cathode 1 is fixed in the electrolyte tank 10, the electrolyte tank 10 is fixed on the movable machine tool table, and the workpiece anode 5 is fixed on the machine tool;

[0029] Bringing the tool cathode 1 into contact with the workpiece anode 5;

[0030] The processing gap between the tool cathode 1 and the workpiece anode 5 is set, and the circulating electrolyte provided by the electrolyte pump 8 flows through the gap, and the working current between the tool cathode 1 and the workpiece anode 5 flows through the electrolyte in the processing gap. Dissolving workpiece anode 5 for processing;

[0031] The workpiece anode 5 is fixed on the lower end of the main shaft 4 of the machine tool, and the workpiece anode 5 rotates at high speed during processing.

[0032] In the above steps, the rotational speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com