Maskless locality micro electro-deposition additive manufacturing device and method based on ultrasound

A technology of additive manufacturing and electrodeposition, which is applied in the field of additive manufacturing, can solve the problems of large grains, low steepness, and low density, and achieve the effects of fast deposition speed, strong localization, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

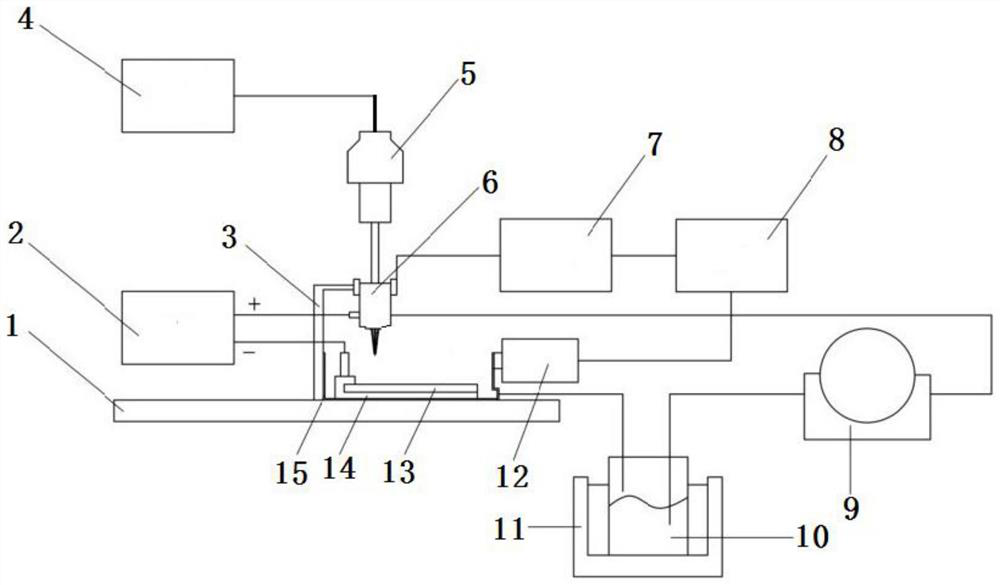

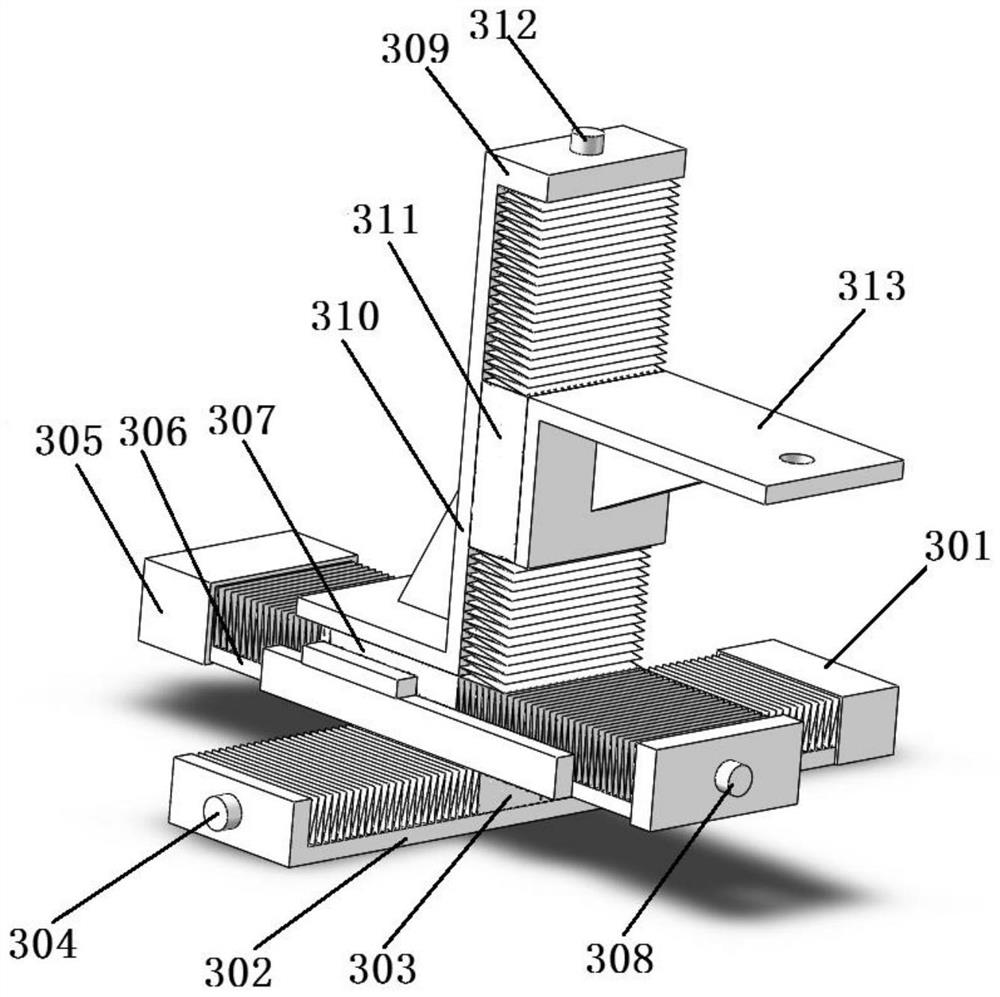

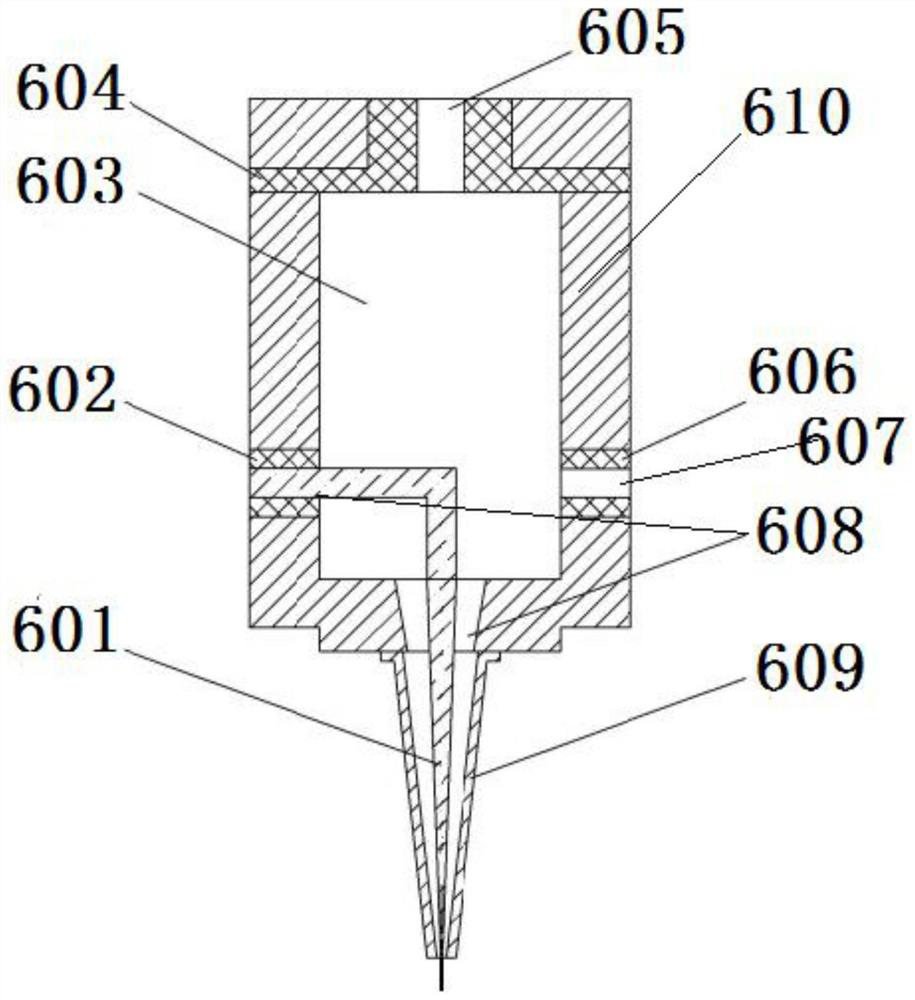

[0034]Ultrasound-based maskless localization micro-electrodeposition additive manufacturing device, including vibration isolation operation platform 1, pulse power supply 2 (Chengdu Xingtongli, GKDMZ), precision positioning system 3 (Sanying Precision Control, ETS-100RG), ultrasonic generator 4, ultrasonic transducer 5, anode module 6, working electrode 13, precision positioning control motor 7 (Sanying Precision Control, PMC400-3), computer 8, peristaltic pump 9, plating liquid circulation tank 10, thermostatic water bath 11, industrial camera 12, Deposit cell 15, deposit cell bracket 14; pulse power supply 2 negative electrode 13 fixed to the deposit cell bracket 14 is connected and the positive electrode is connected to the anode module 6, when the device is working to provide electrical energy to the working electrode 13 and the anode module 6, after powering on the anode module 6 and the working electrode 13 generate an electric field, the metal ions in the plating solution a...

Embodiment 2

[0038]Ultrasonically based on the maskless localized micro-electrodeposition additive manufacturing method, the application of the ultrasonic based on the ultrasound-based localized micro-fine electrodeposition additive manufacturing apparatus, the principle of electrochemical deposition combined with the concept of additive manufacturing, increase the acoustic chemical effect to refine the grain, so that the micrometallic structure is dense. The following steps are included, in order.

[0039] Step 1: Configure the plating solution and add nickel sulfamate (Ni (NH 2 SO 3 ) 2 ·4H 2 O) 300g, nickel chloride (NiCl 2 30 g, boric acid (H 3 BO 4 30g, placed in plating solution circulation tank 10;

[0040] Step 2: Prepare the copper sheet for the working electrode 13, the size is 10 * 30 * 2mm;

[0041] Step three: the use of acetone solution to clean the working electrode 13, the use of ultrasonic cleaning machine to the working electrode 13 immersed in deionized aqueous solution clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com