Method for recovering potassium chloride from abandon mine of salt lake

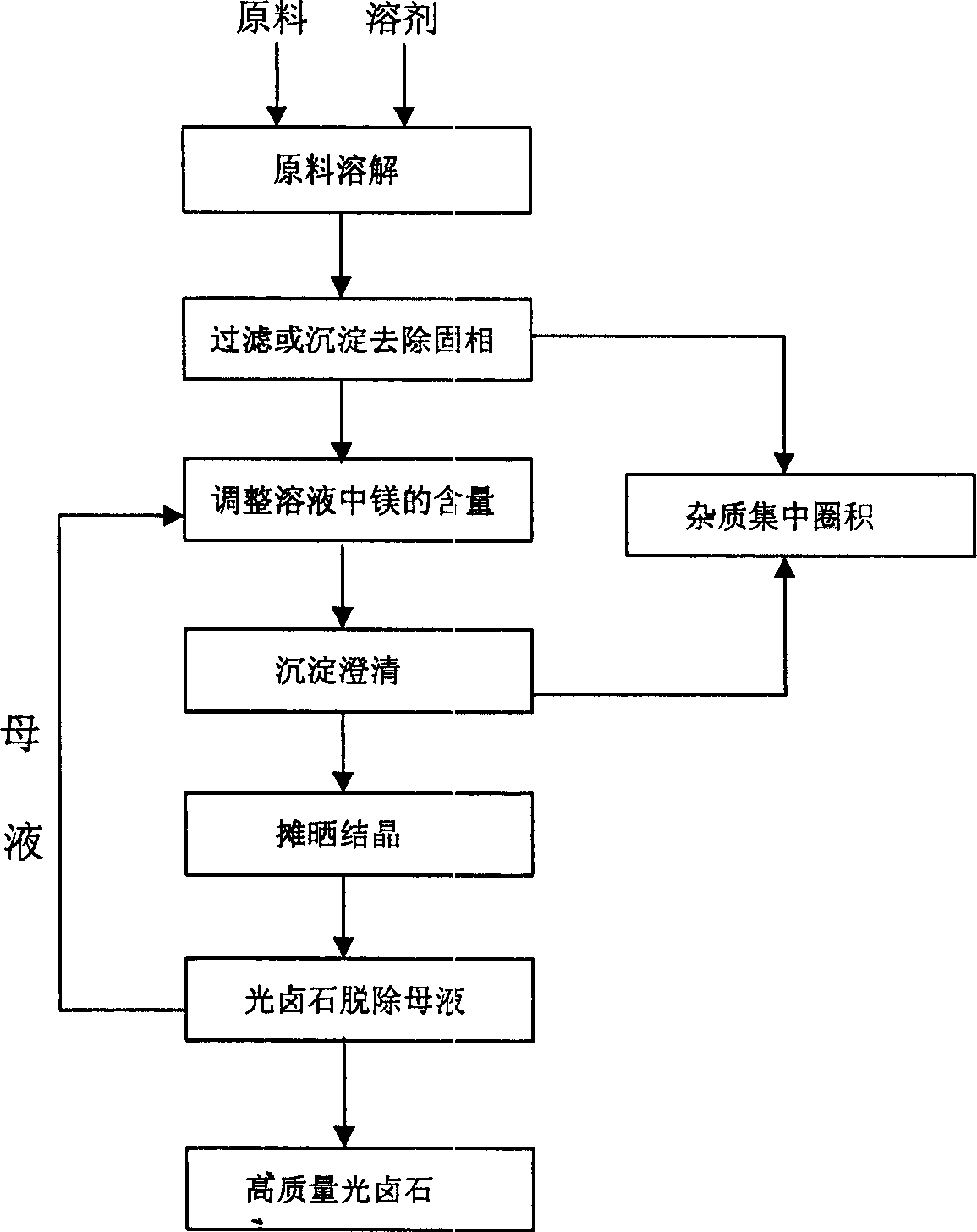

A recovery method and technology of potassium chloride, applied in the direction of alkali metal chlorides, etc., can solve the problems of digging the farm and harming oneself, discarding it, and the potassium fertilizer products are not up to the standard, and achieve the effect of extending the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: Take by weighing 20T potassium chloride content of 5.3%, calcium sulfate content of 3%, sodium chloride content of 69.6%, magnesium chloride content of 8%, and water insoluble matter of 13% salt lake abandoned ore, and 26T of fresh water, stirring Fully stir in the tank to completely dissolve the potassium chloride in the abandoned mine into the solution; send the stirred suspension solution together with the salt sand to the sedimentation tank to obtain 22.1 tons of clarified solution; Stir and mix the saturated magnesium chloride solution with a concentration of 35Be in a stirring tank, send it to a sedimentation tank for overnight precipitation, and pump 56 tons of clear solution to the drying tank for natural drying. When the concentration of the solution is 35Be at 20°C , and the mother liquor was filtered to obtain 3.69 tons of carnallite with a potassium chloride content of 18.2%, a calcium sulfate content of 0.94%, a sodium chloride content of 13.2%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com