Fully automatic high-speed air-jet loom in wide size

An air-jet loom, fully automatic technology, used in looms, textiles, textiles and papermaking, etc., to achieve the effect of improving sensitivity, reducing warp pressure, and maintaining a stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

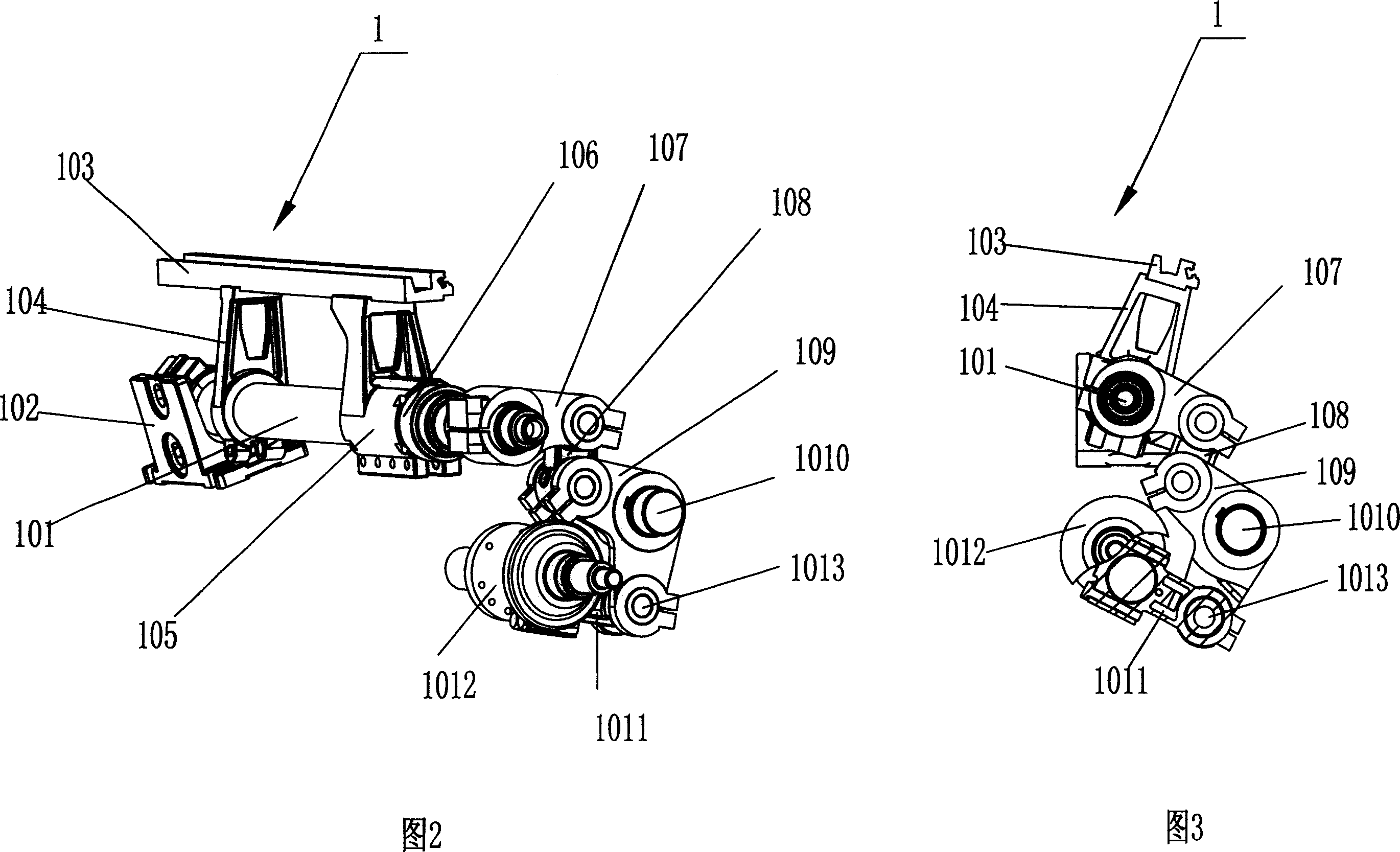

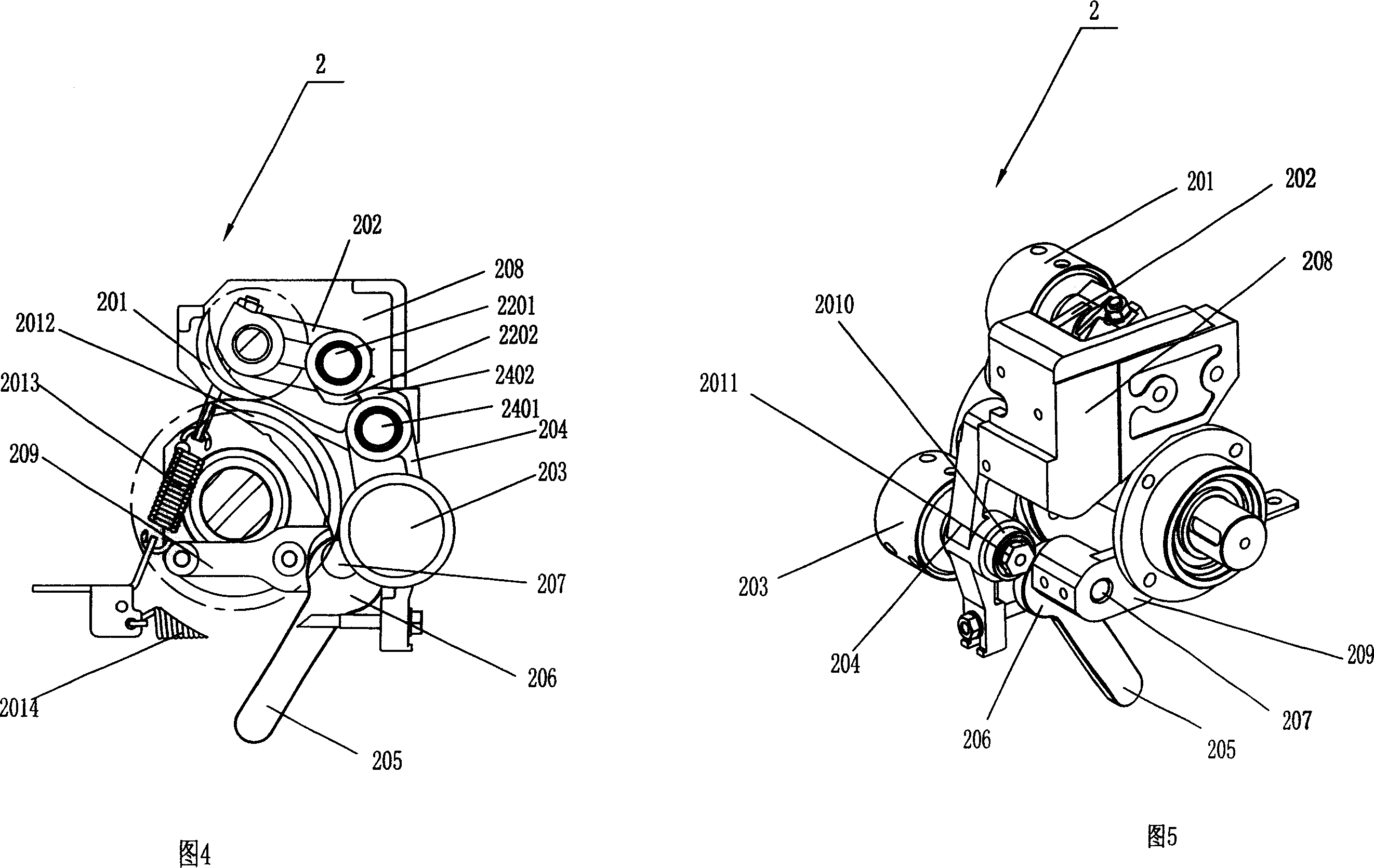

[0025] The technical parts not mentioned in the present invention can be adopted or realized by referring to the prior art. The following focuses on the technical content of several innovative parts in a fully automatic high-speed wide-width air-jet loom of the present invention. The innovative parts include a fully automatic control system, a weft beating mechanism, double press rollers and a backrest.

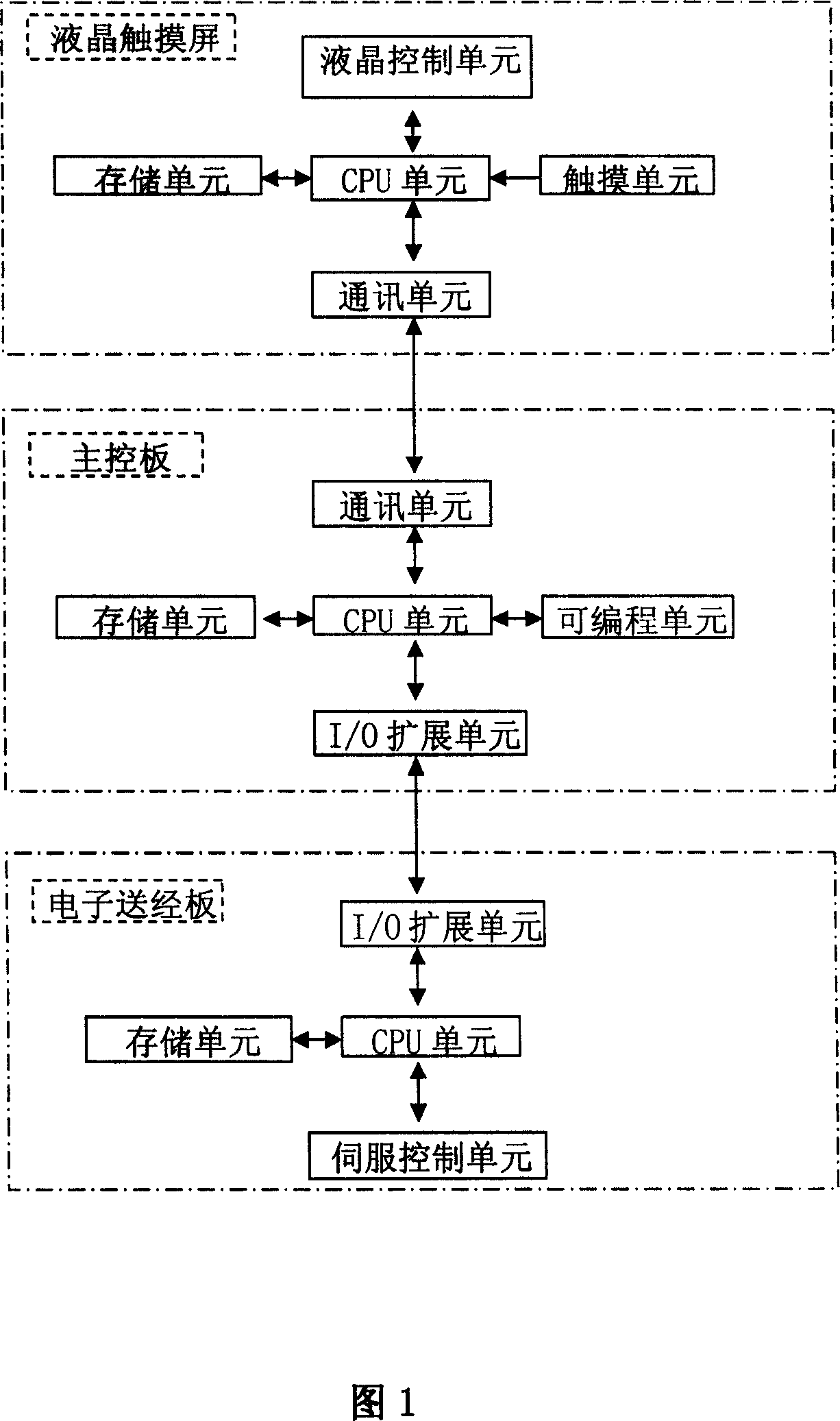

[0026] 1. Fully automatic control system, referring to Figure 1, the main control board in its hardware composition is used as the main controller, the electronic let-off board is connected with the main control board through I / O and bus expansion interface, and the man-machine interface adopts multi- Functional LCD touch screen, connected to the main control board through RS422 serial communication. The main control board, the electronic warp let-off board and the LCD touch screen are respectively equipped with CPUs. Each CPU can use a 16-bit single-chip microcomputer. Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com