Core of integrative calorimeter

A technology of heat meter and water inlet flow, applied in the direction of measuring heat, calorimeter, measuring device, etc., can solve the problems such as impurity can not be flushed regularly, loose connection and leakage at joints, irregular water discharge, etc., to improve the measurement effect and measurement accuracy, prevent leakage and loose connections, and ensure reliable and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

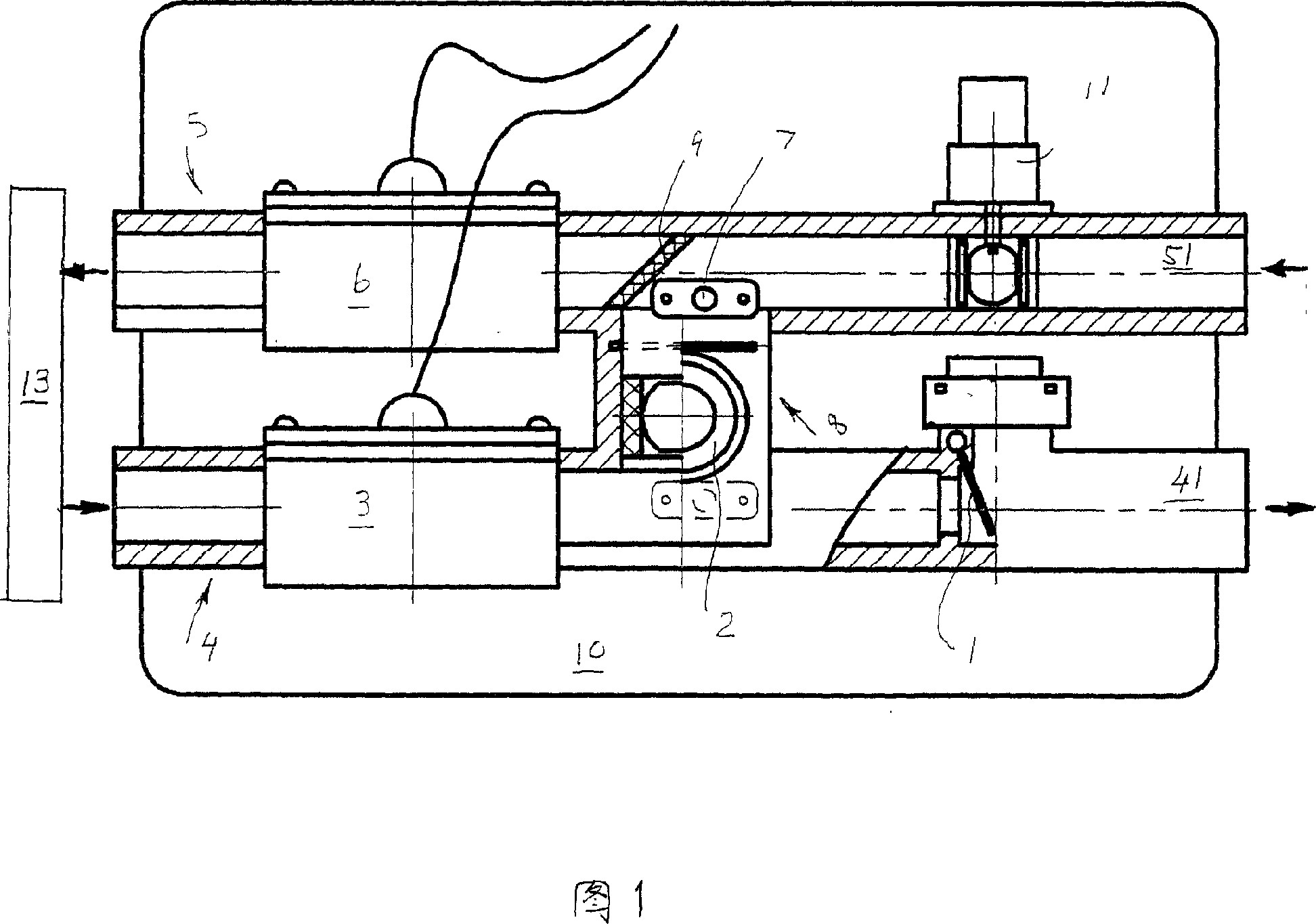

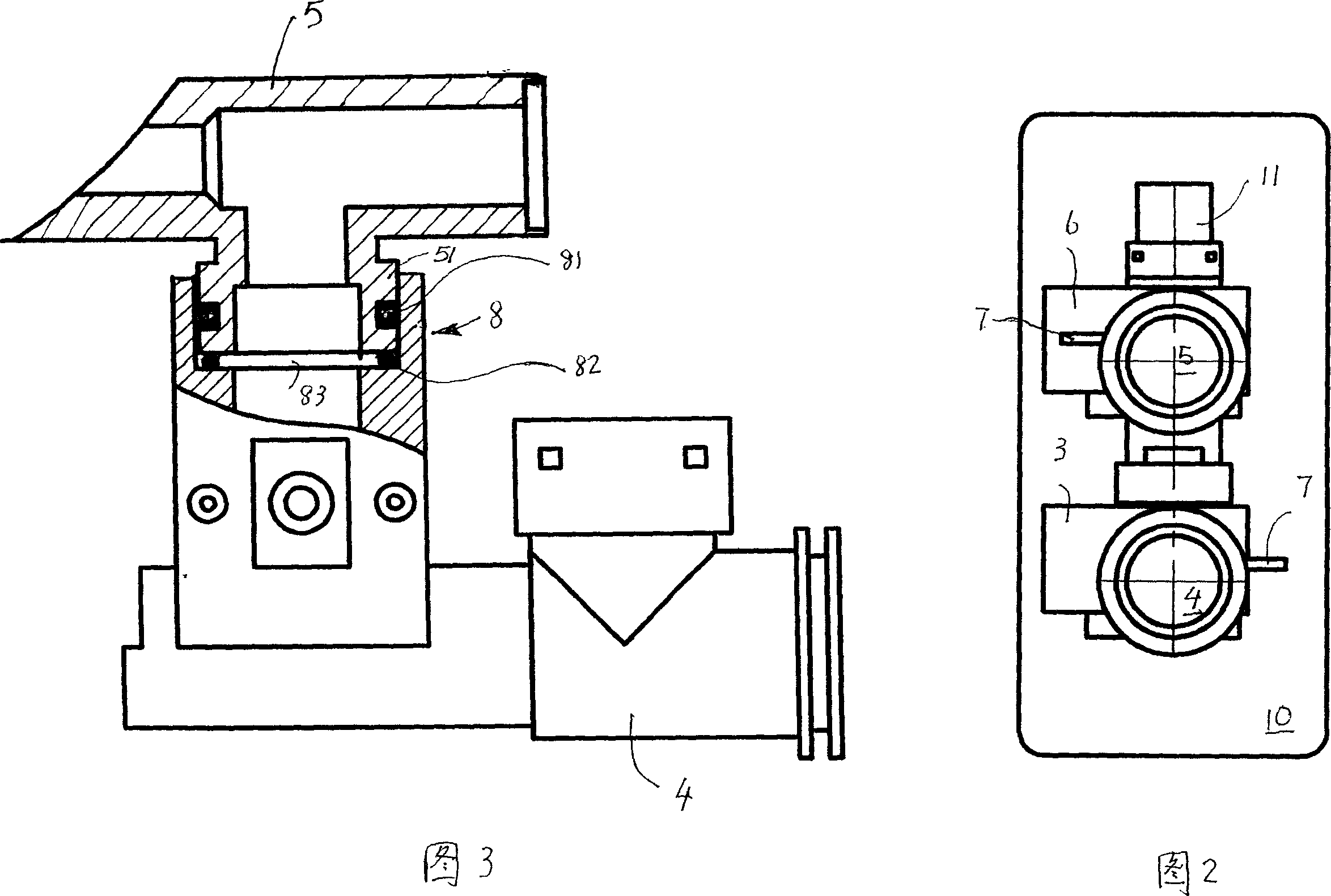

[0020] 1 to 3 show the embodiment of the integrated heat meter core of the present invention. Including the water inlet pipe 5 and the return water pipe 4 installed in the meter body 10; the rear end of the water inlet pipe 5 is connected with a water inlet flow sensor 6, and the front end of the return water pipe 4 is connected with a return water flow sensor 3; as shown in FIG. 1 . The flow sensor uses the water flow in the pipeline to drive the impeller to rotate, and uses the principle of electromagnetic induction to generate pulse numbers, which are then converted into corresponding flow rates and converted into heat. The combined use of the inlet water flow sensor 6 and the return water flow sensor 3 can play a role in balancing measurement and overcome many shortcomings of a single sensor heat meter. For example, users are prohibited f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com