Apparatus and method for fabricating cathode collectors for lithium/oxyhalide electrochemical cells

A technology of current collectors and mixtures, applied in the field of electrochemical batteries, can solve problems such as not being able to be used as active cathode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

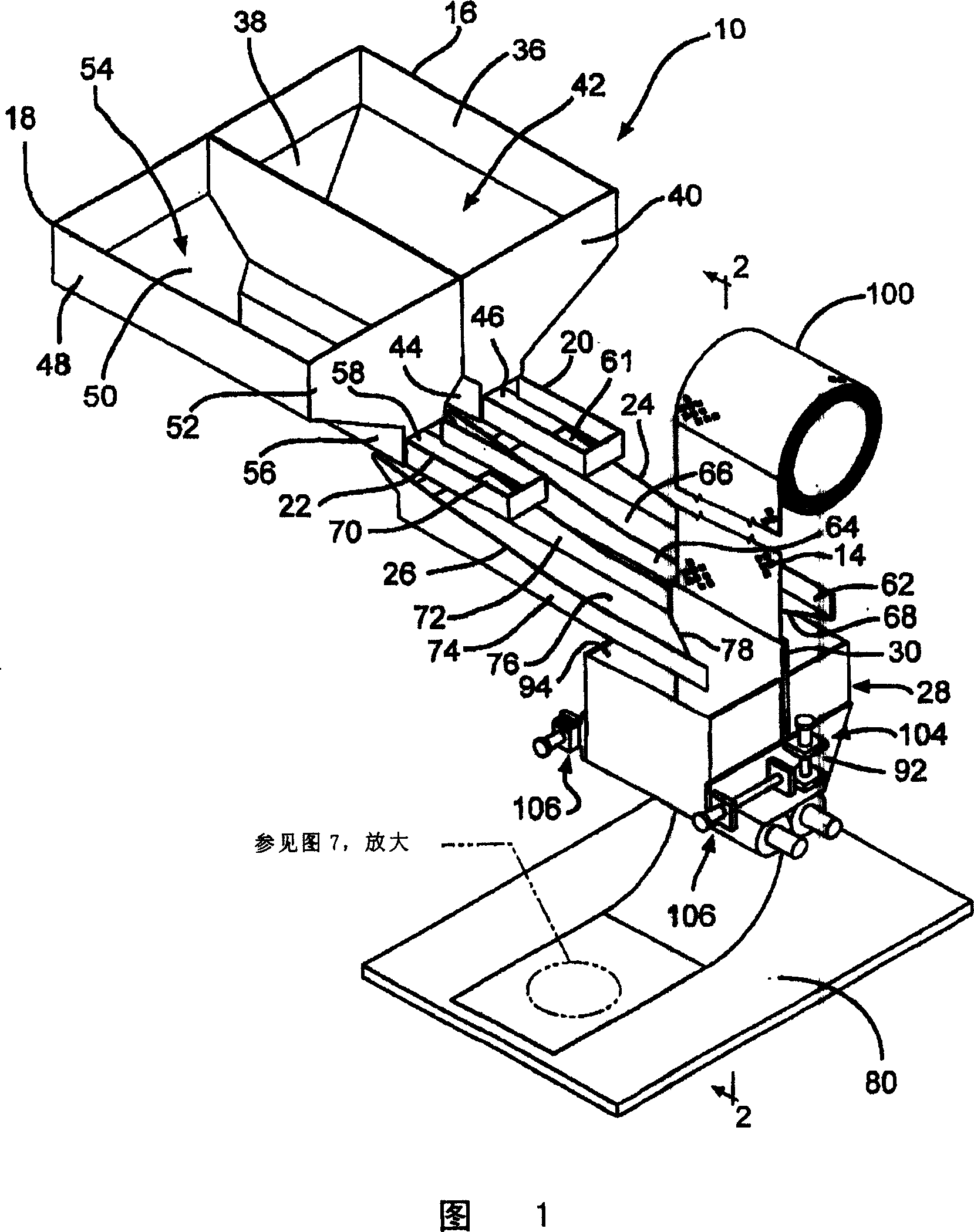

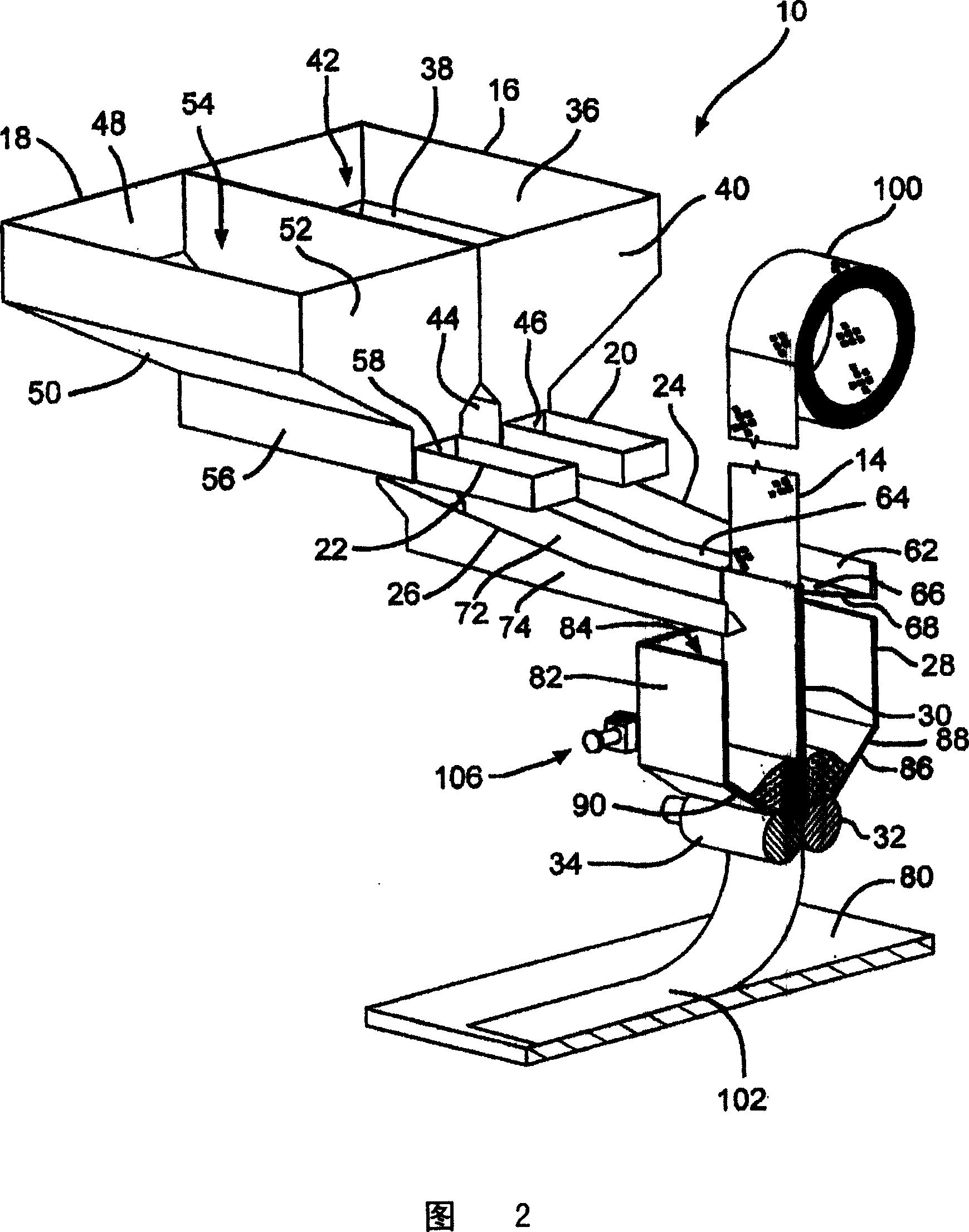

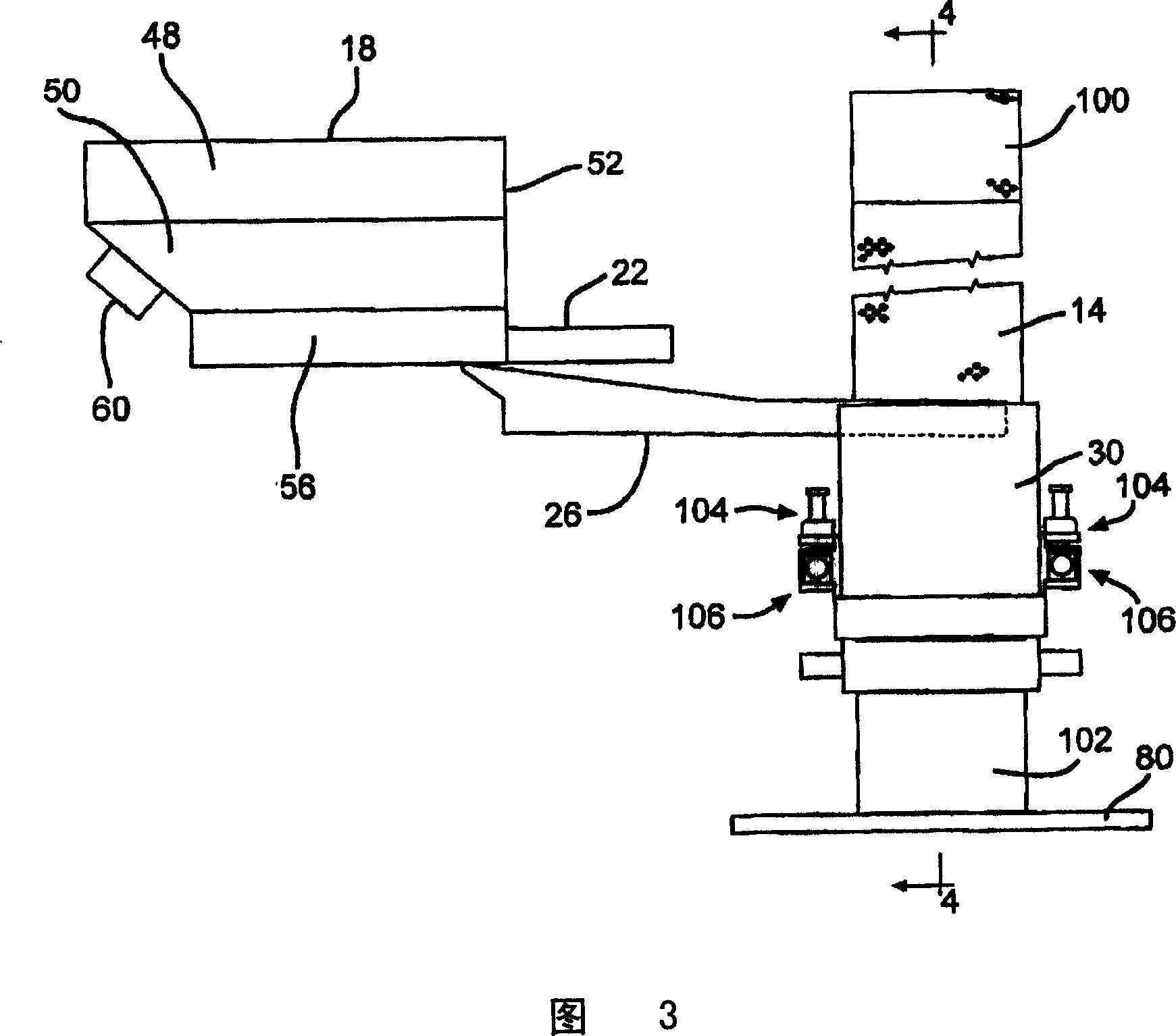

[0019] The present apparatus is particularly useful in the manufacture of cathode current collector structures such as pressed carbonaceous powder current collectors for lithium / oxyhalide electrochemical cells. More specifically, however, the present device can be used to fabricate "electrode" structures for primary and secondary chemical batteries. The structure of a galvanic cell includes a positive electrode with a liquid catholyte system of conductive or electroactive material supported on a current collector substrate or a solid cathode active material supported on a current collector.

[0020] Regardless of the configuration of the cell, such cells preferably comprise an anode active material of a metal selected from Group IA, IIA or IIIB elements of the Periodic Table of the Elements, including the alkali metals lithium, sodium, potassium, etc., and alloys and intermetallic compounds thereof, such as Li-Mg, Li-Si, Li-Al, Li-B, Li-Al-Mg and Li-Si-B alloys and intermetall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com