Section type rectifier for electronic accelerator

A technology of electron accelerators and rectifiers, which is applied in the direction of electrical components, accelerators, etc., can solve the problems of occupying limited internal space of rectifiers, difficult maintenance, and tip discharge, so as to overcome the problem of tip discharge, good rectification effect, and save internal space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

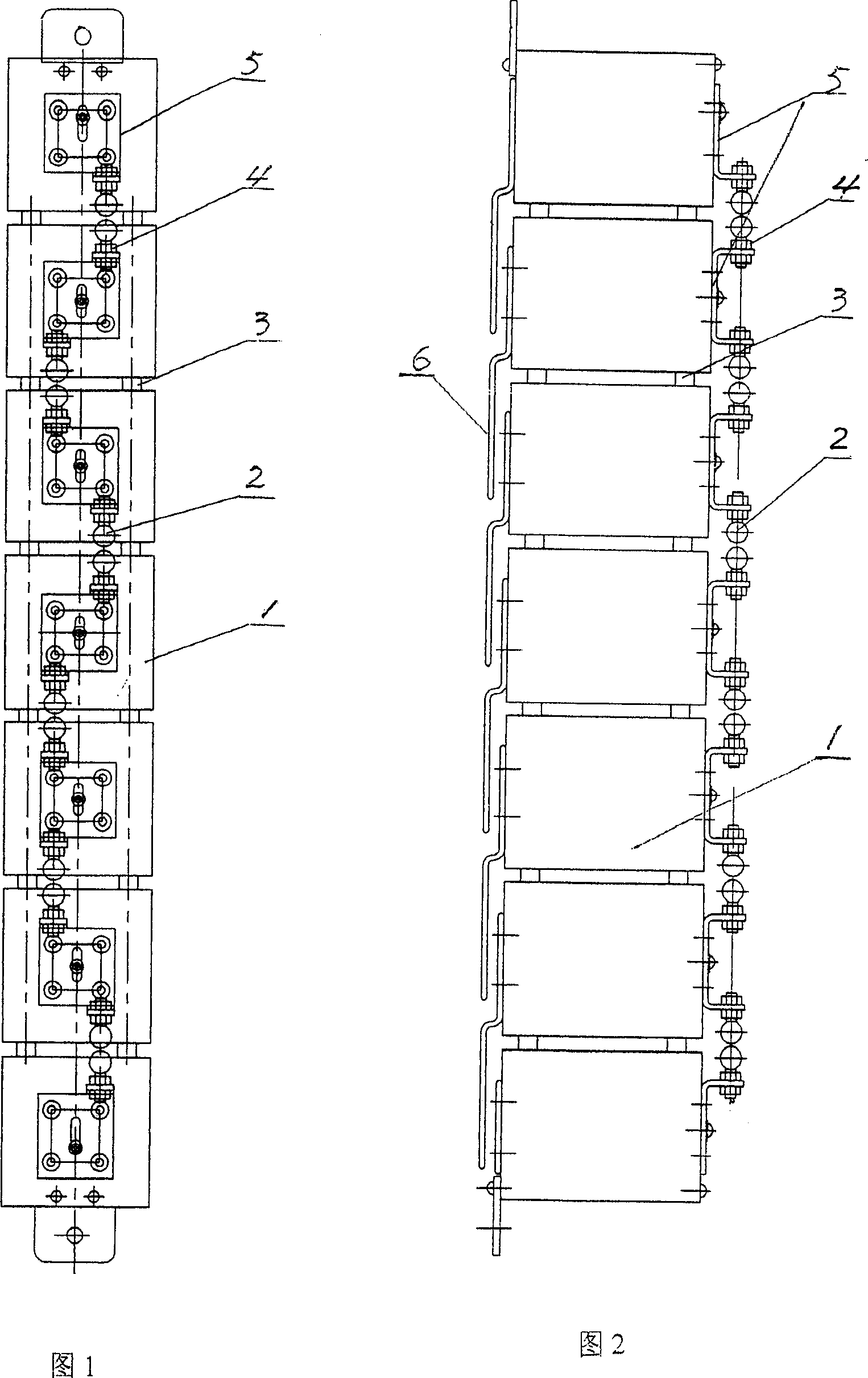

[0011] As shown in Fig. 1 and Fig. 2, the segmented rectifying device for an electron accelerator of the present invention contains seven rectifying boxes 1, and these rectifying boxes 1 are cuboids with shielding sleeves on their outside, and they pass through four connecting rods 3 connected together. The same end surface of the rectifier box 1 is provided with a fixing plate 5, which is processed into a U-shape so that their two ends are tilted upward. The horizontal section of the U-shaped fixing plate 5 is fixed on the end face of the rectifier box 1, and they are arranged along the connection direction of the rectifier box 1, and discharge balls 2 are installed on their two tilted ends. Said discharge ball 2 is all welded with a screw mandrel, and the two ends of the fixed plate 5 are all processed with through holes, and the discharge ball 2 is fixed on the two ends of the fixed plate 5 by means of the nut 4, the screw mandrel on it and the through hole. There is a gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com