Glassy matrices for the stabilization of coffee aroma

A fragrance, glass-like technology, applied in the direction of coffee flavor, coffee, coffee extraction, etc., can solve the problem of not being disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Example 1: Preparation of an inert matrix by treatment with polyvinylpolypyrrolidone

[0073] A 2% aqueous solution of soluble coffee (90 g of soluble coffee, total weight 4500 g) was incubated intermittently with 225 g of polyvinylpolypyrrolidone. After stirring with a rotary stirrer for 1 h at room temperature, the suspension was filtered through a frit. Two washes were performed by resuspending the PVPP remaining on the frit in 900 ml of cold water (4° C.), stirring it for a few minutes, and filtering again. The filtrates were pooled and treated with a second crop of PVPP (113 g). After stirring for 1 h at room temperature, the suspension was worked up as before. Finally, all filtrates were collected and lyophilized to obtain 73 g of PVPP-treated matrix. As a result, the total recovery was 81%. Chlorogenic acid content was determined to be 20% of the feed.

Embodiment 2

[0074] Example 2: Preparation of an inert matrix by ultrafiltration

[0075] A laboratory scale hollow fiber system operated in feed discharge mode (continuous mode) was used for this ultrafiltration test. Backwash antifouling technology is applied, whereby the permeate is periodically backwashed back into the retentate. In feed-to-discharge operation, feedstock is continuously fed to the membrane system, and both retentate and permeate are discharged at constant flow rates.

[0076] The solids content of the coffee extract used for the ultrafiltration test was 7.5%. The coffee was heated to 60°C for 5 minutes, cooled to room temperature, and centrifuged (Sorvall RC 5C, rotor GS3, 8900 rpm at 16-20°C within 30 minutes) in batches of 500 ml to remove insoluble material. The final coffee solution (6.3% total solids) was stored frozen until used for ultrafiltration testing. This feedstock is called ultrafiltration feedstock.

[0077] To investigate the effect of the individ...

Embodiment 3

[0089] Example 3: Tests to Determine Reduction in Fragrance Breakdown Levels

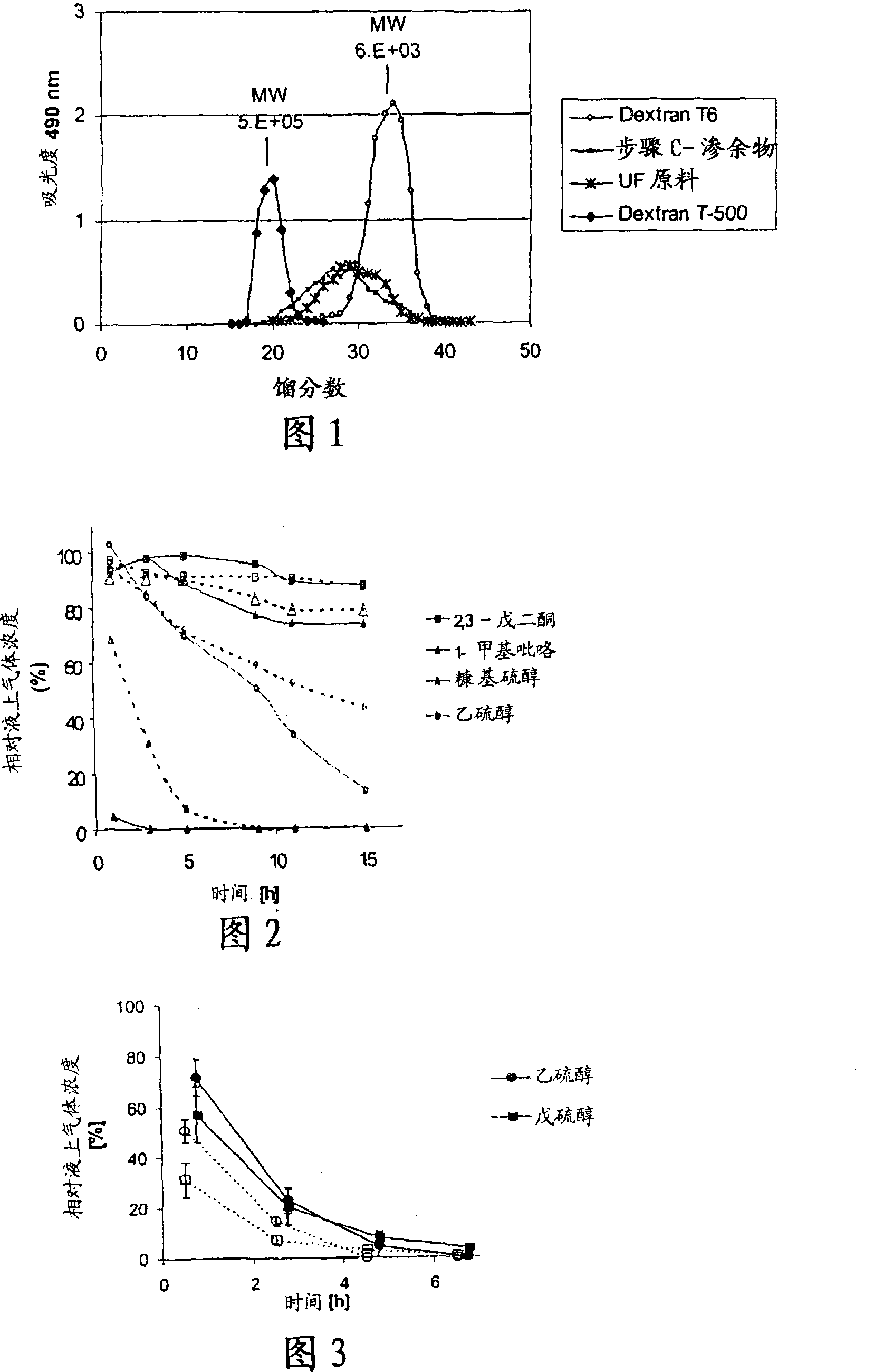

[0090]Evaluation of aroma potential stability of processed coffee extracts in solution. The relative change in headgas concentration of volatile simulated mixtures was tracked over time in the presence of untreated and treated coffee matrices. The SPME-GC-MS peak areas at given time intervals were measured and expressed as a percentage of the peak area in white water (blank reference) for the same volatile mock mixture. Figures 2 and 3 show that the kinetic rate constants for volatile decay are 10-100 times lower in the treated matrix than in the feedstock, where Figure 2 is for UF retentate sample B (dashed line) and UF feedstock (solid line ) in the presence of volatile simulated mixtures, Figure 3 is a graph of the decomposition kinetics of volatile thiols in the presence of PVPP-treated samples (solid line) and untreated coffee extract (dashed line) .

[0091] Coffee samples containing arom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com