Vehicle component

A component and automobile technology, applied to engine components, metal processing equipment, machines/engines, etc., can solve the problems of chip formation, high cost, blocking hydraulic channels, etc., and achieve low cost, good sealing effect, and simple manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

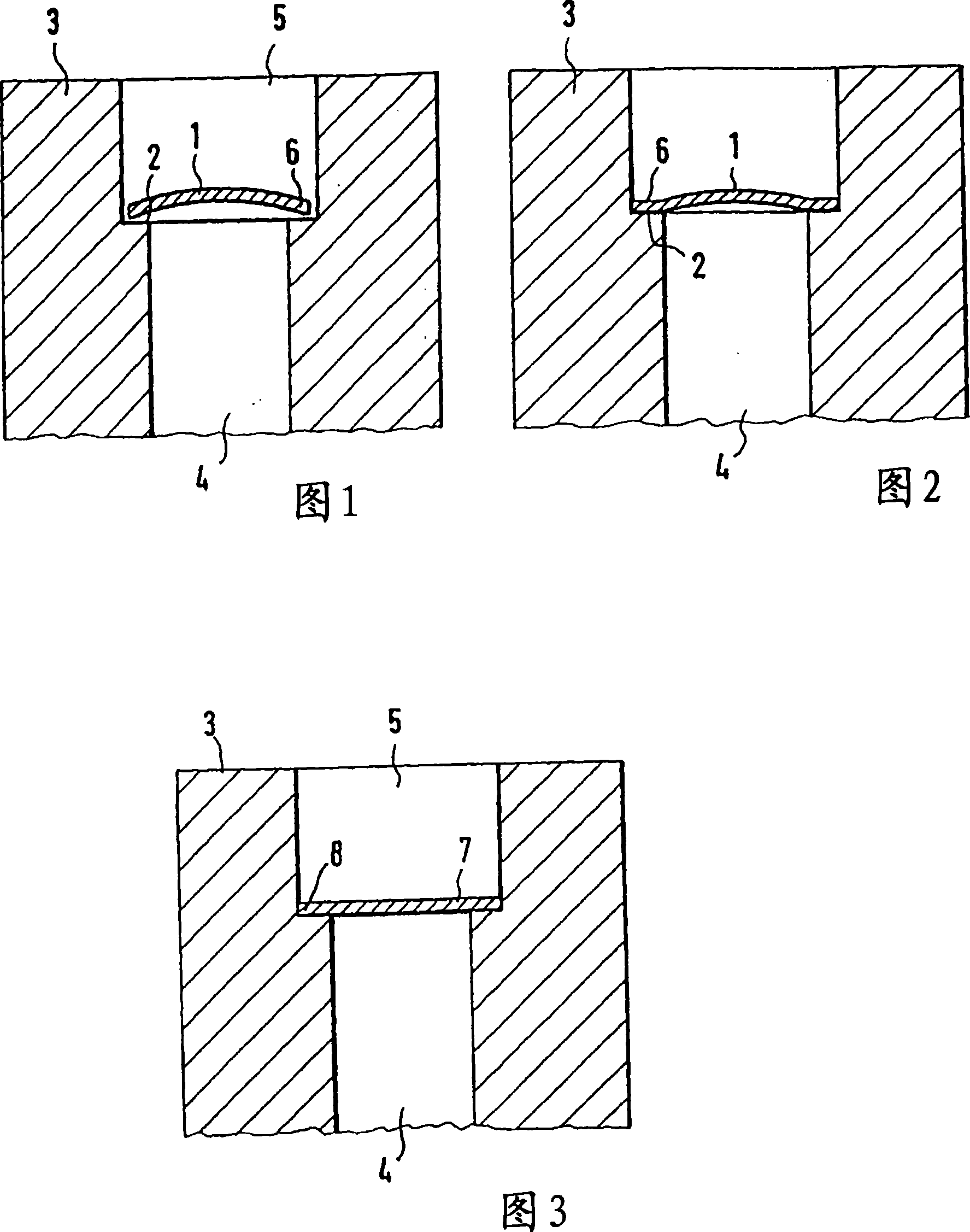

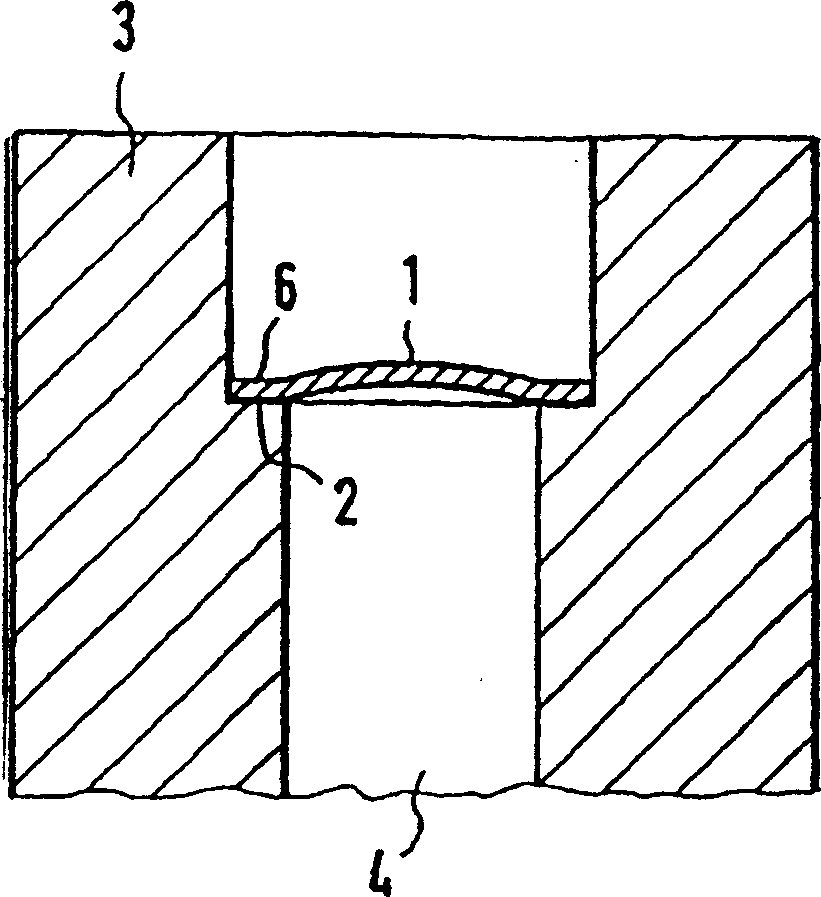

[0019] The sealing disc 1 has a round basic shape with a dome. In the exemplary embodiment shown, a sealing disc according to DIN 470 is used which, for example, has a thickness of 1.6 mm and a bending radius of 22 mm at a diameter of 16 mm. The sealing sheet 1 is provided with an electroplated surface protection layer, which can be phosphated, for example.

[0020] as in figure 1 It can be seen from the figure that the sealing sheet 1 rests on the shoulder 2 of the vehicle component 3 during installation. This vehicle component 3 is a module carrier for a chain tensioner, which is provided with an orifice 4 for creating a built-in oil sump for the hydraulic system.

[0021] Such as figure 1 As shown, for mounting, the sealing disc 1 is inserted loosely with its convex side outwards into the opening 5 of the vehicle component, wherein the inner diameter of the opening 5 is chosen to be somewhat larger than the outer diameter of the sealing disc 1 . Since there is a small g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com