A semiconductor pump micro-slice laser

A technology of microchip lasers and semiconductors, applied in the field of lasers, can solve problems affecting the structure, application and cost of semiconductor pumps, and achieve the effects of easy implementation and adjustment, cost saving, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

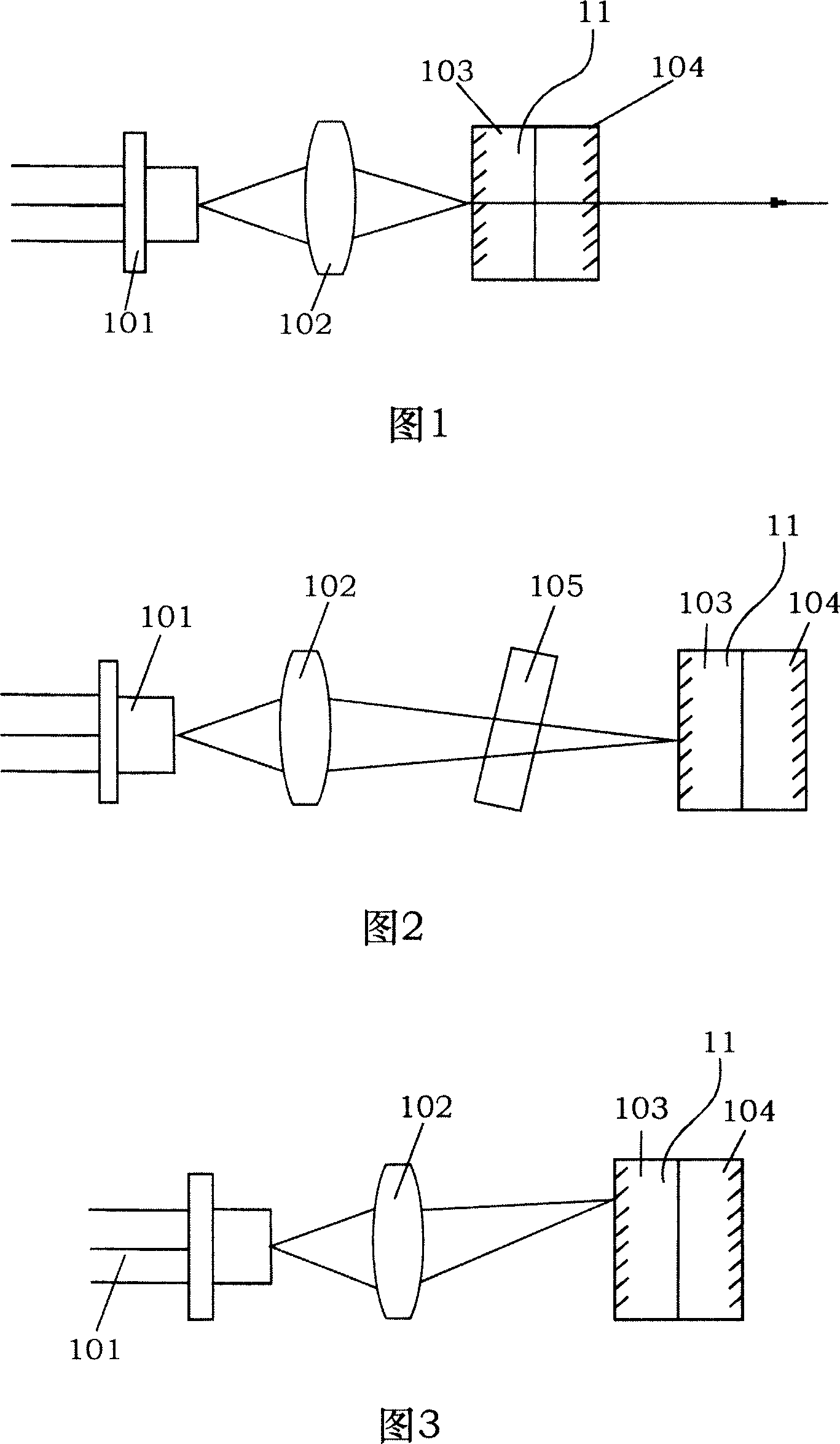

[0021] Embodiment 2: As shown in FIG. 3 , the optical lens coupling system 102 is made rotatable, and its central axis is offset parallel to the rotational central axis, so as to achieve the goal of moving the pumping point.

[0022] The third embodiment: as shown in Figure 4, a mechanical structure 114 is set outside one, two or three of the pumping source semiconductor laser 101, the optical lens coupling system 102 and the microchip laser 11, so that they pass through the light vertically The surface translation of the direction can make the position of the pumping spot on the microchip laser 11 move.

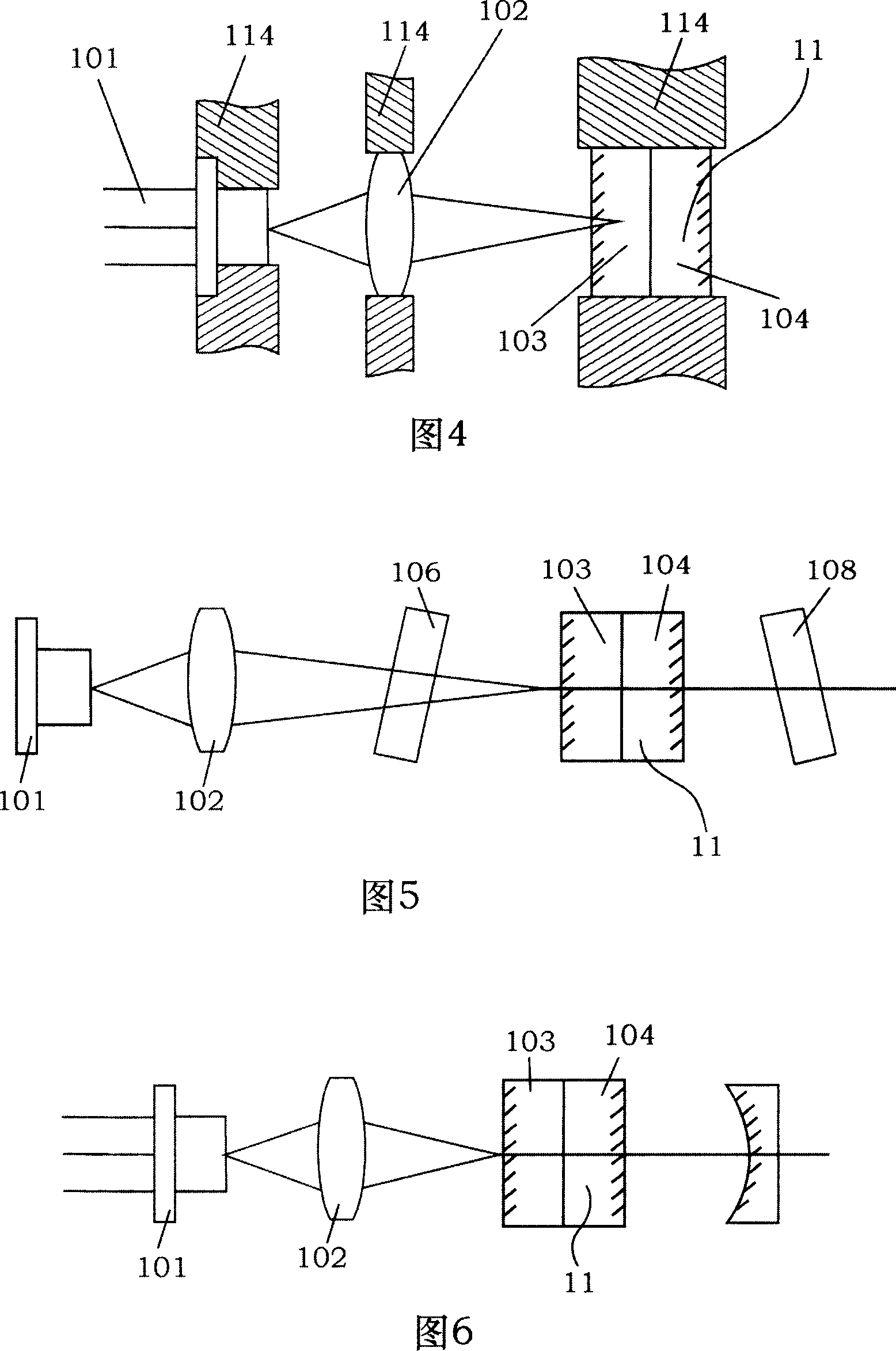

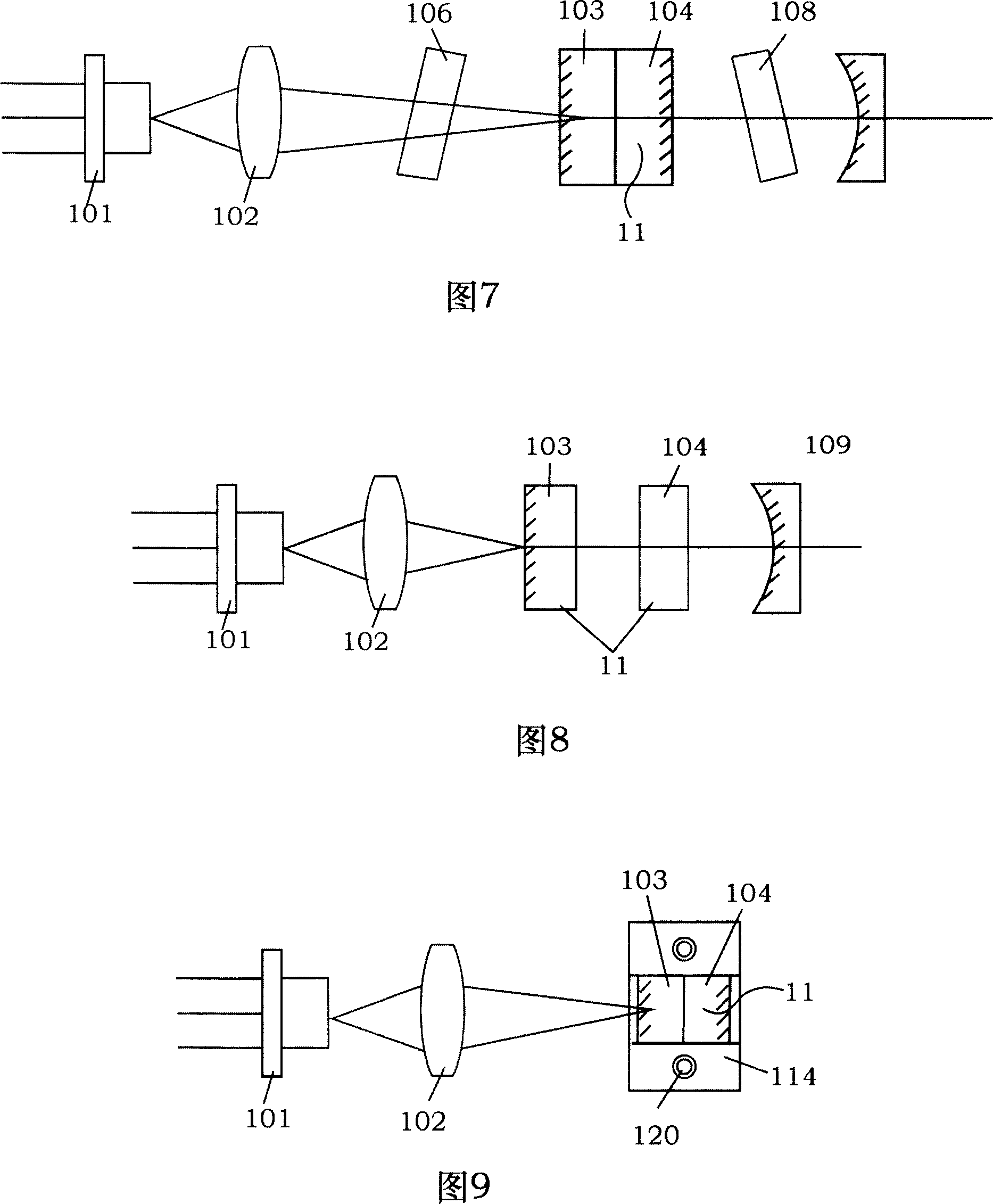

[0023] Embodiment 4: As shown in Figure 5, the first optical parallel plate 106 is inserted between the optical lens coupling system 102 and the microchip laser 11, and the pumping point is moved on the microchip laser 11. Then insert the second optical parallel plate 108, and translate the optical path back to the original output position.

[0024] Embodiment 5: As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com