Processing method and apparatus for rack

A processing equipment and processing method technology, applied in metal processing equipment, mechanical equipment, metal sawing equipment, etc., can solve the problem of relatively high torque output requirements of machine tools, racks that cannot meet processing requirements, and long processing time, etc. problems, to achieve the effect of improving the smoothness, increasing the service life and reducing the amount of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

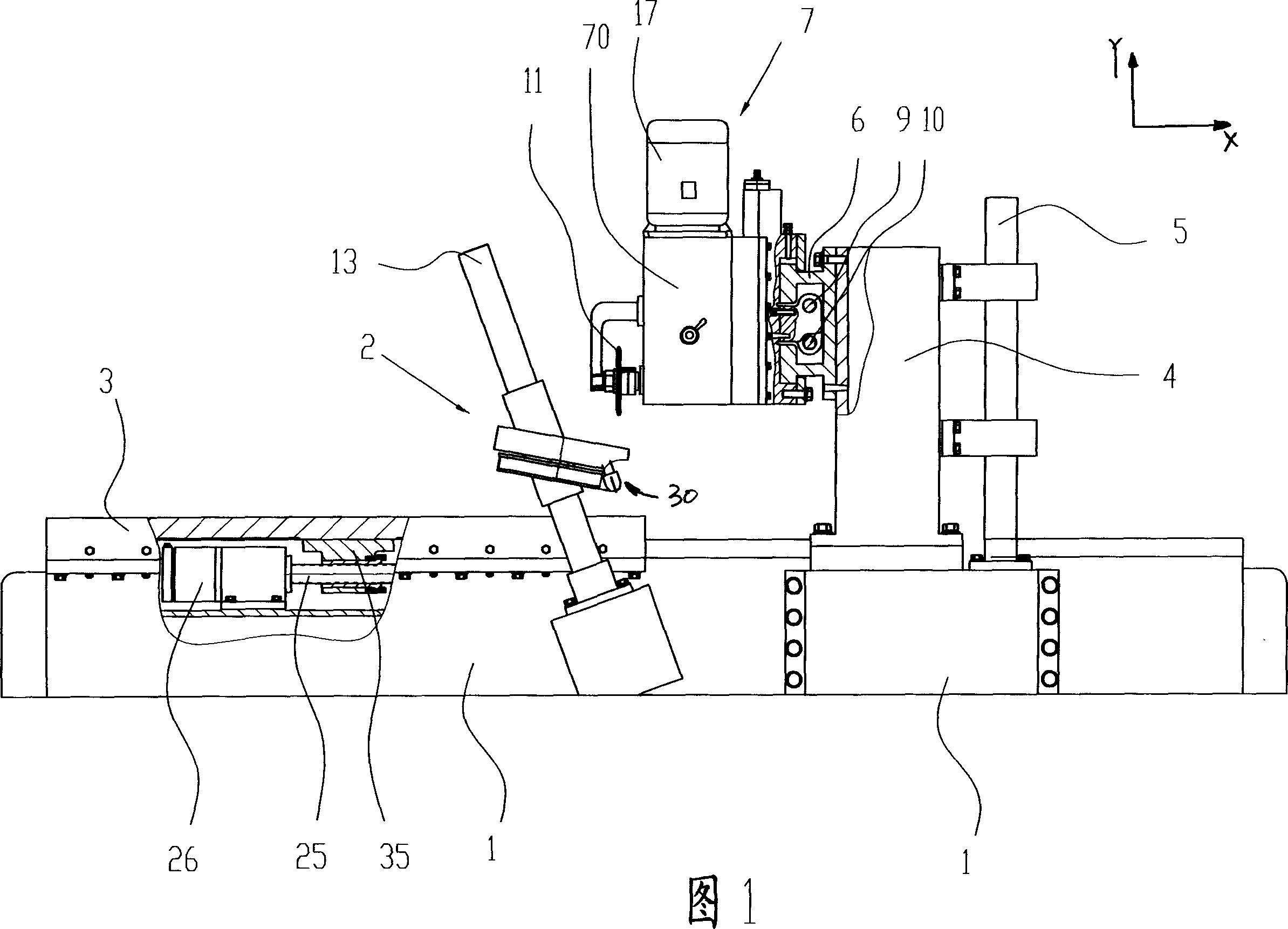

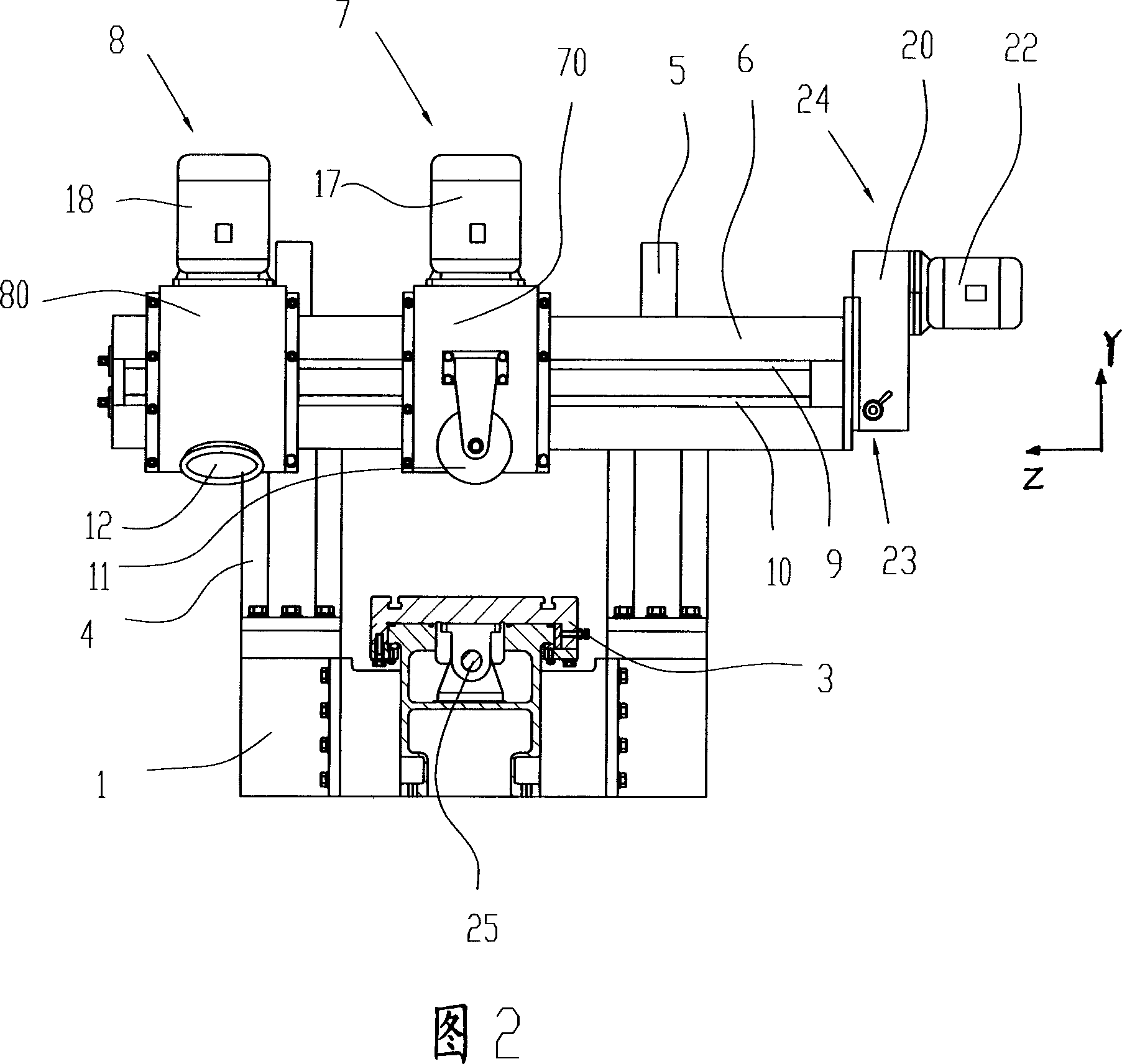

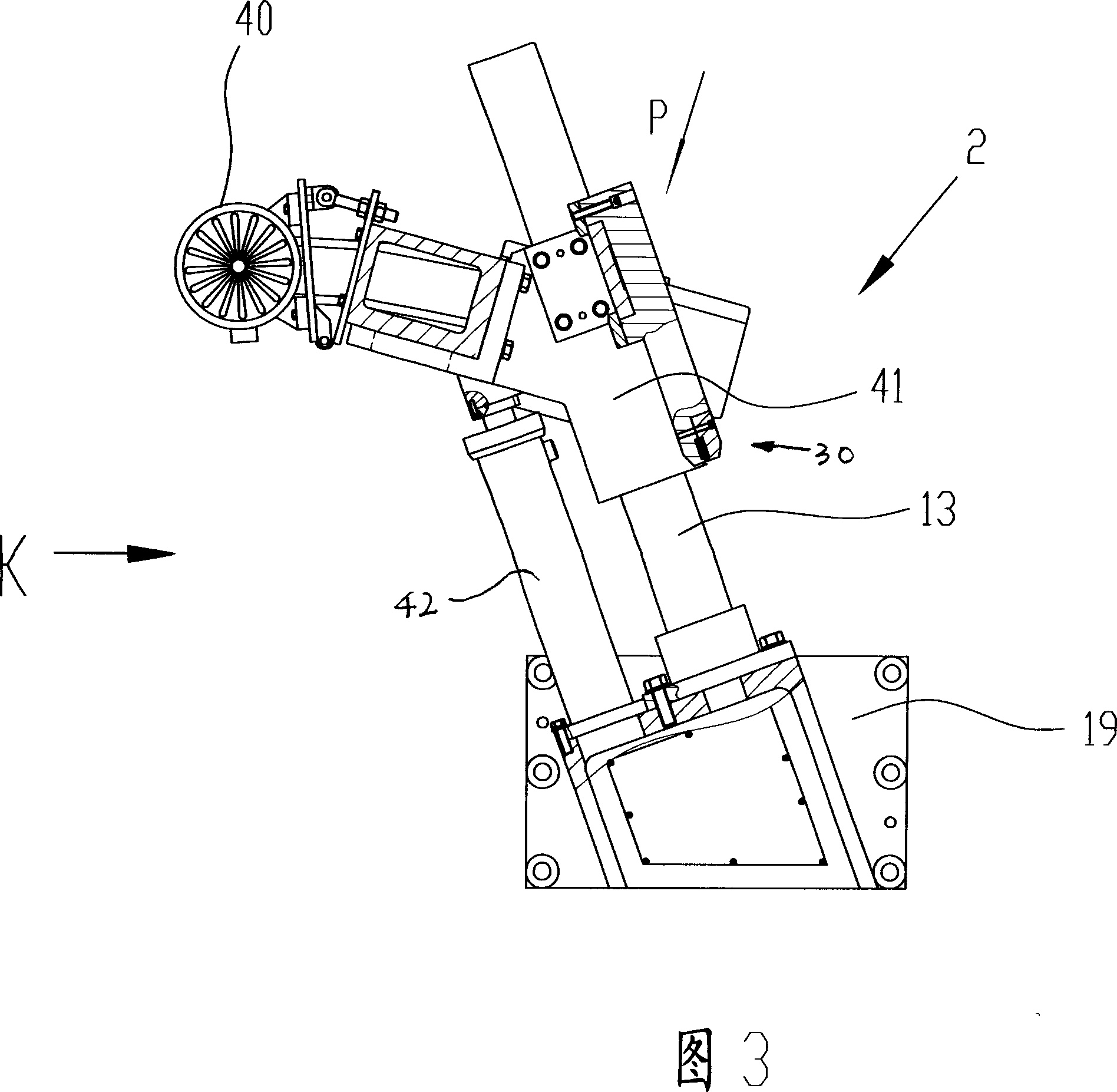

[0049] Referring to the accompanying drawings, the present invention provides a rack processing method, comprising the following steps:

[0050] a. Place the blank 91 to be processed on the drilling machine, predetermine the specifications of the tooth grooves 95 to be processed, and drill holes 92 on the blank 91 according to the preset tooth grooves 95 (as shown in Figures 19-21), to ensure The hole 92 is tangent to the groove bottom 96 of the formed alveolar 95, and the surfaces where the hole 92 and the groove walls 97 on both sides of the alveolar 95 are located are also tangent to each other;

[0051]B, cut along the groove wall 97 of the tooth groove 95 with a saw, remove the scrap piece 93 after cutting, and obtain the preliminary formed tooth rack 94' (seeing in Figure 22);

[0052] c. Carry out milling processing to the preliminary formed rack 94' to obtain the required rack 94 (see Figure 23).

[0053] Wherein, the milling processing method of step c is to feed the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com