Manufacturing method of multilayer gold-containing card

A production method and gold-containing card technology, applied in information-carrying cards, sports accessories, printing, etc., can solve the problems of embedding magnetic stripes or chips, unable to provide information, and affecting the appearance of cards, etc., to achieve long service life and beautiful appearance Luxurious, the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

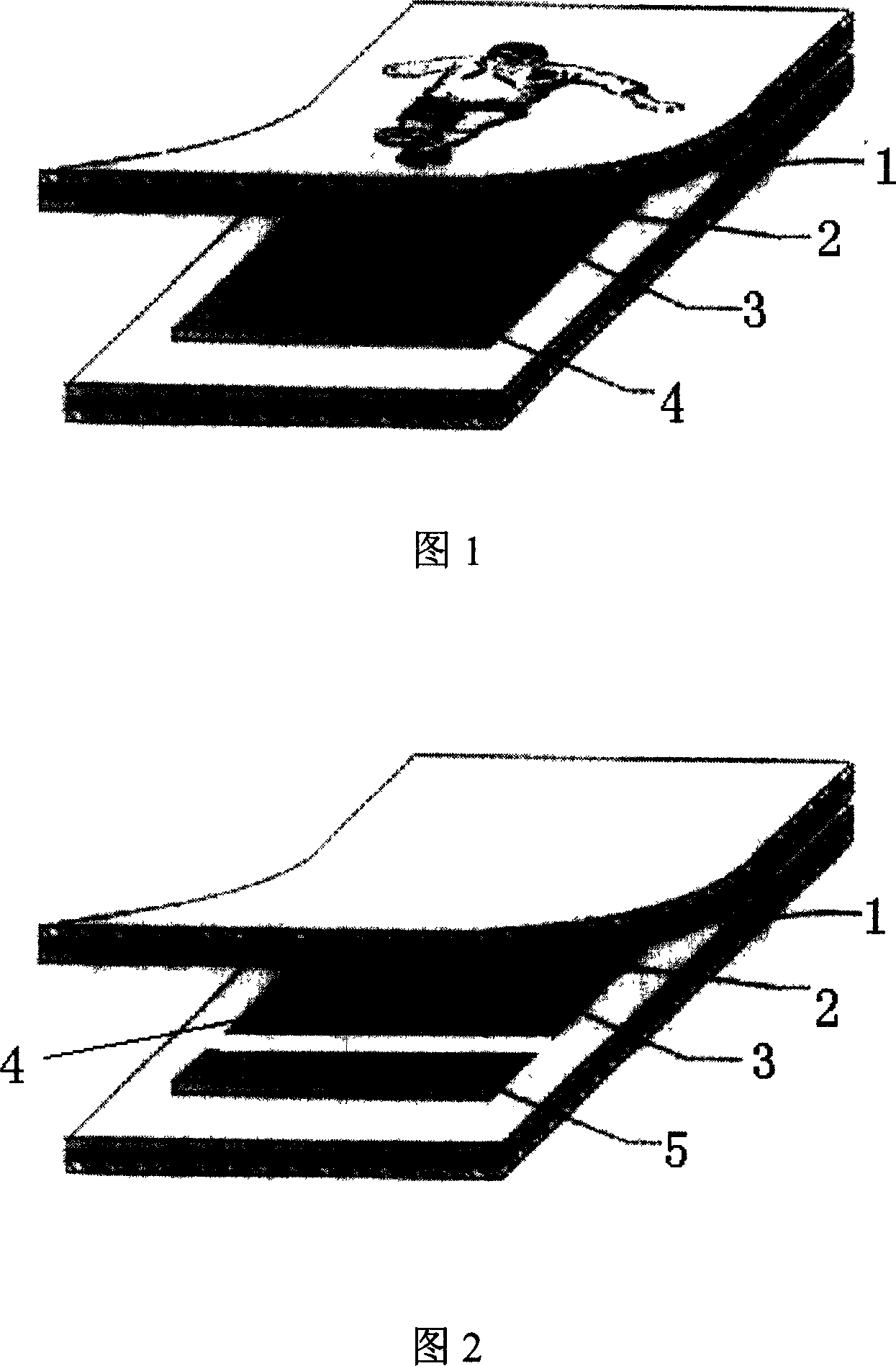

[0017] The multi-layer gold-containing playing cards as shown in Figure 1, its manufacture method is: be coated with thermosol on one side of the PET polyester film 2 that thickness is 30 μm, become the thermosol layer 3 that thickness is 55 μm, then on polyester film The other side of 2 is plated with a layer of gold with a thickness of 0.08 μm, that is, the gold-plated layer 1. Put two gold-plated film hot-sol layers 3 facing each other, sandwich a gold sheet 4 in the middle, composite molding under high temperature and high pressure, and then gold-plated Print the required characters or patterns on layer 1, and coat it with a protective layer to prevent abrasion.

Embodiment 2

[0019] The multi-layer gold-containing playing cards as shown in Figure 1, its manufacture method is: on one side of the PET polyester film 2 that thickness is 75 μ m, coat hot melt, become the hot melt layer 3 that thickness is 65 μ m, then on polyester film The other side of the 2 is plated with a layer of gold with a thickness of 0.12 μm, that is, the gold-plated layer 1. Two gold-plated film hot-sol layers 3 are put together facing each other, and a gold sheet 4 is sandwiched between them. They are compositely formed under high temperature and high pressure, and then gold-plated. Print the required characters or patterns on layer 1, and coat it with a protective layer to prevent abrasion.

Embodiment 3

[0021] The multi-layer gold-containing playing cards as shown in Figure 1, its manufacture method is: be coated with hot melt glue on one side of the PET polyester film 2 that is 55 μm in thickness, become the hot melt glue layer 3 that thickness is 60 μm, then on polyester film The other side of 2 is plated with a layer of gold with a thickness of 0.1 μm, that is, the gold-plated layer 1. Put two gold-plated thin film hot-sol layers 3 facing each other, sandwich a gold sheet 4 in the middle, composite molding under high temperature and high pressure, and then gold-plated Print the required characters or patterns on layer 1, and coat it with a protective layer to prevent abrasion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com