Corrosion resistant marsh gas tank and manufacturing method thereof

A manufacturing method and biogas tank technology, applied to biochemical equipment and methods, gas production bioreactors, biochemical instruments, etc., can solve problems such as easy generation of pores or delamination, uneven coating of slurry, and increase of unfavorable links , to achieve the effect of improving construction production efficiency, uniform slurry distribution and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

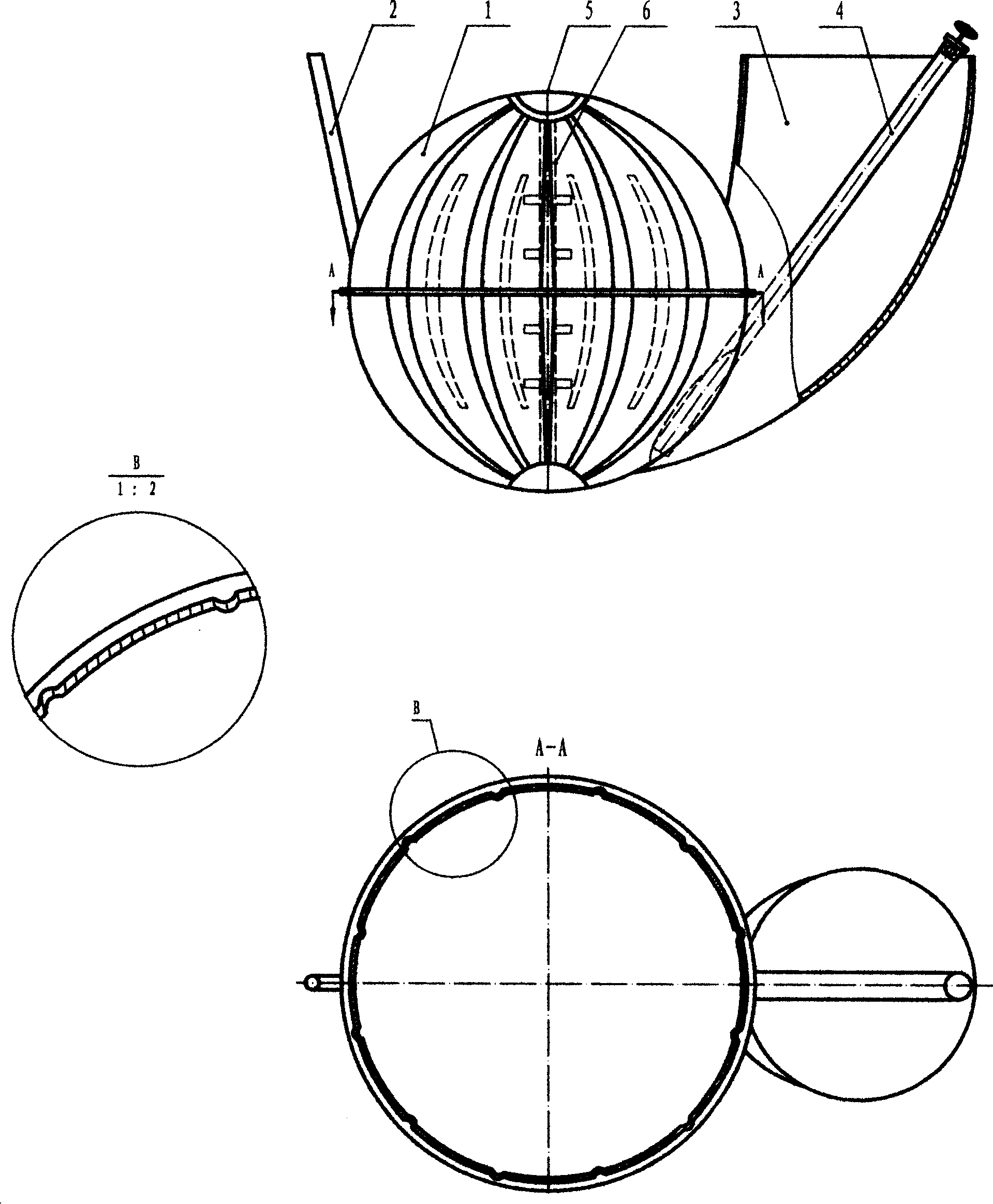

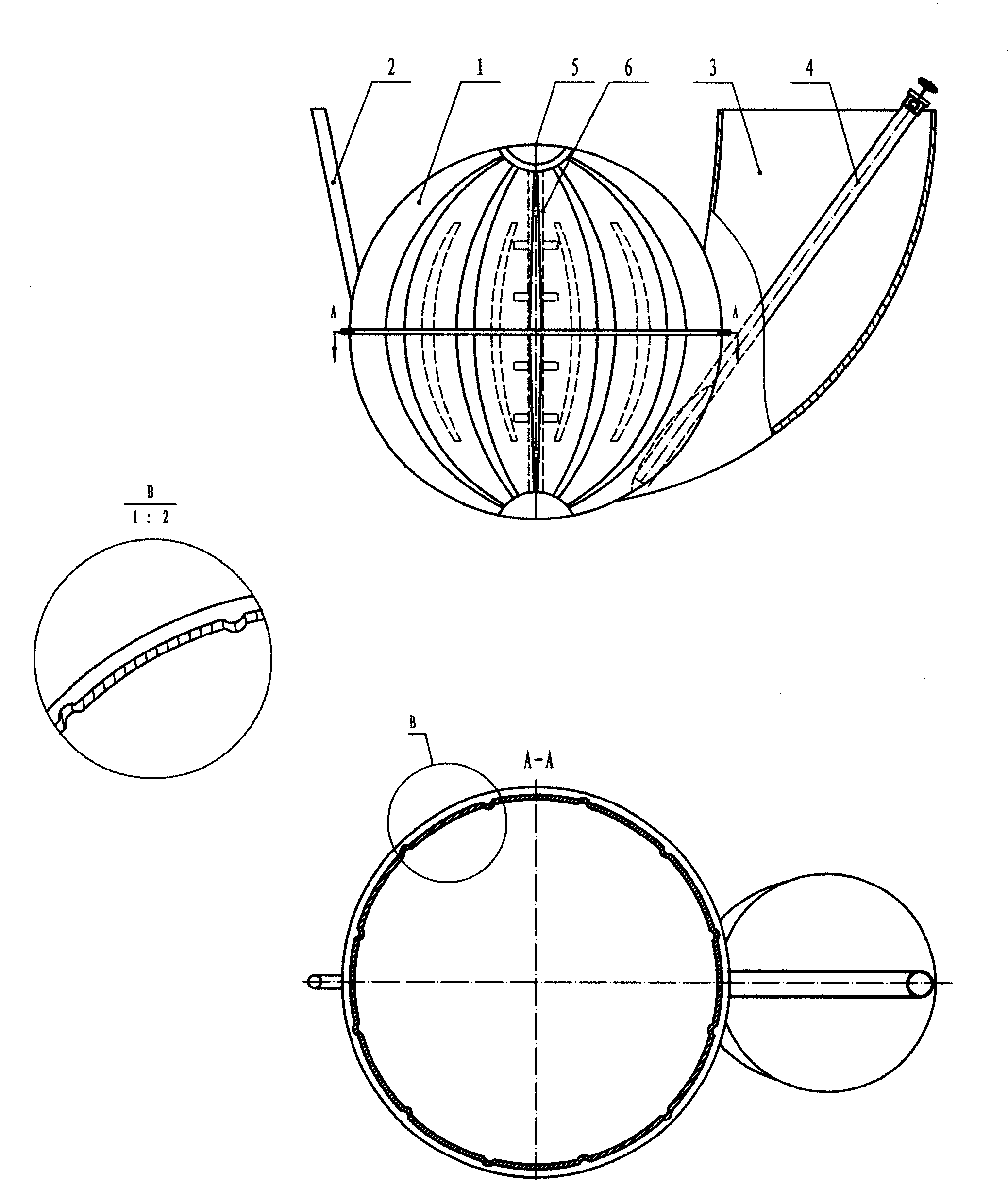

[0012] A novel corrosion-resistant biogas tank includes a tank body (1), a feed inlet (2), a water pressure chamber (3) and a slag extractor (4). The tank body is spherical, the feed liquid enters the tank body from the feed port, and there is a vent hole on the top of the tank body. After the biogas slurry is fermented in the tank body, gas is generated, which is comprehensively utilized through the gas outlet through the pipeline; it is made separately The special slag extractor is inserted into the hydraulic room to extract slag.

Embodiment 2

[0014] The surface of the novel rot-resistant biogas tank (1) is composed of an inwardly or outwardly concave-convex multi-arch hyperbolic structure, and the material of the tank (1) is sprayed with compressed air through a slurry spray gun for slurry spray coating. The middle part of the tank body (1) is provided with a shell-breaking post made of a vertically erected anti-corrosion material, on which several anti-corrosion-treated shell-breaking rods are fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com