Heat-treatment method for storage tank body of large-scale total pressure type LPG carrying vessel

An overall heat treatment and transport ship technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as poor hot air flow, poor hot air fluidity, and obstruction of hot air flow, etc., to achieve heat treatment time The effect of shortening, good temperature control effect, and easy heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0029] A method for integral heat treatment of a storage tank of a large full-pressure LPG carrier, which comprises the following steps:

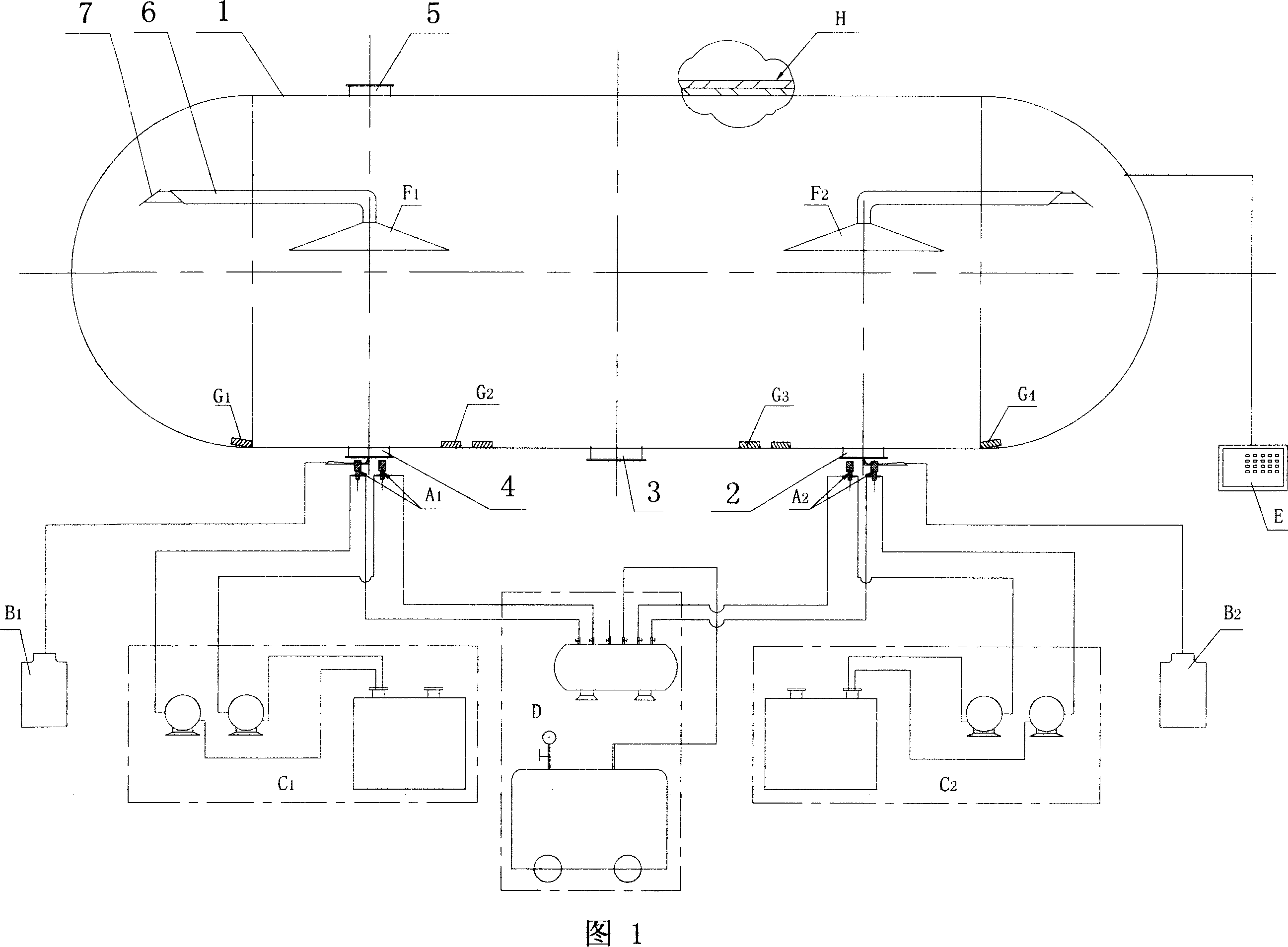

[0030] 1) Before the heat treatment, put the manhole 2 and the deep well pump seat 4 of the storage tank at the bottom of the tank as the air inlet; the storage tank above the manhole is equipped with a second tank internal diversion device F 2 , the storage tank above the base of the deep well pump is provided with a first diversion device F in the tank 1 ;

[0031] The deflector in the tank includes an umbrella cover, a heat pipe 6, a deflector 7, and a support frame. One end of the heat pipe is fixed with an umbrella cover, and the other end of the heat pipe is fixed with a flow guide plate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com