Method for generating plasma photon crystal having three refractivities

A plasma and photonic crystal technology, applied in the field of plasma photonic crystals, can solve problems such as troubles, and achieve the effects of simple device, easy maintenance and easy fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

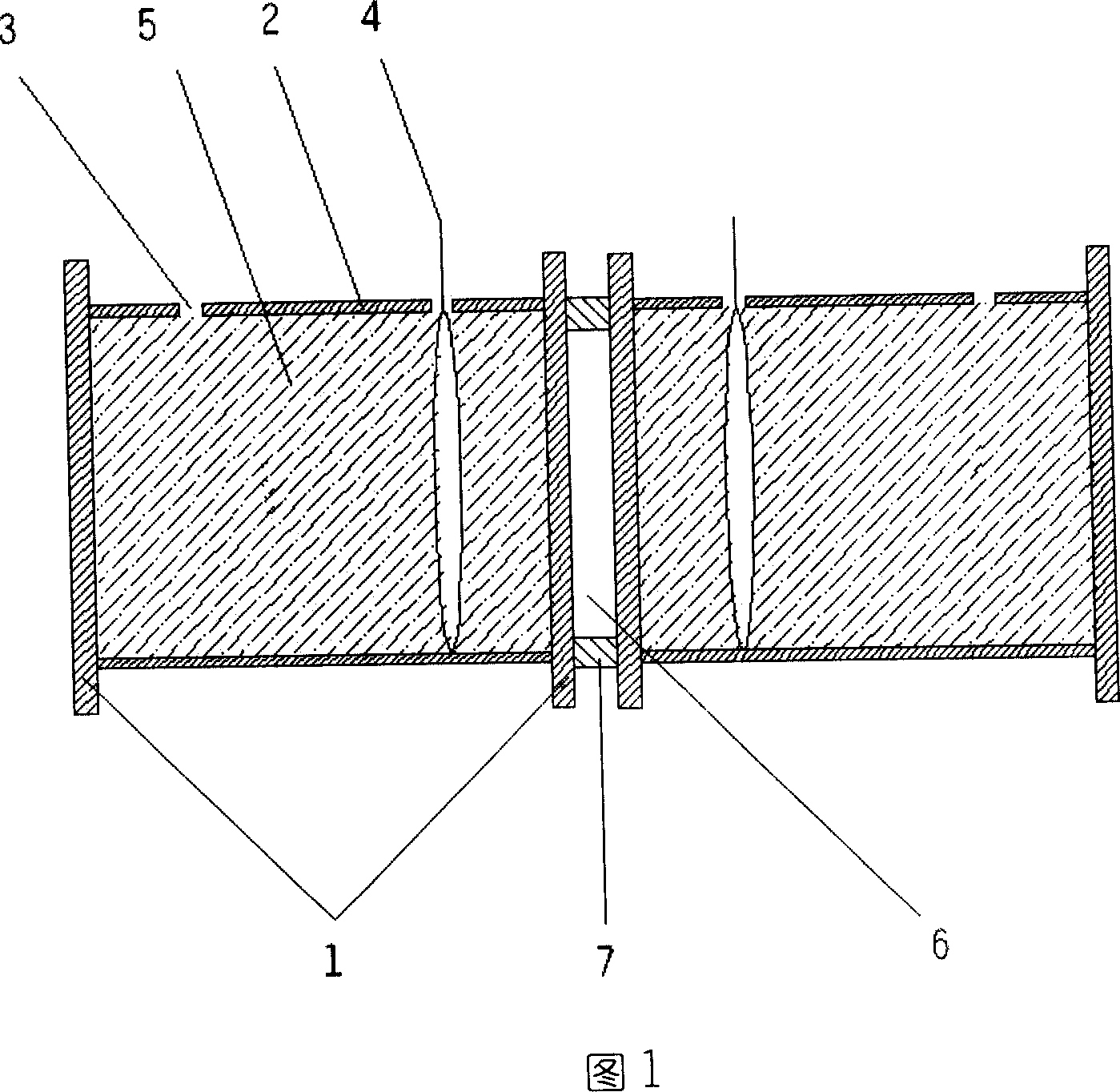

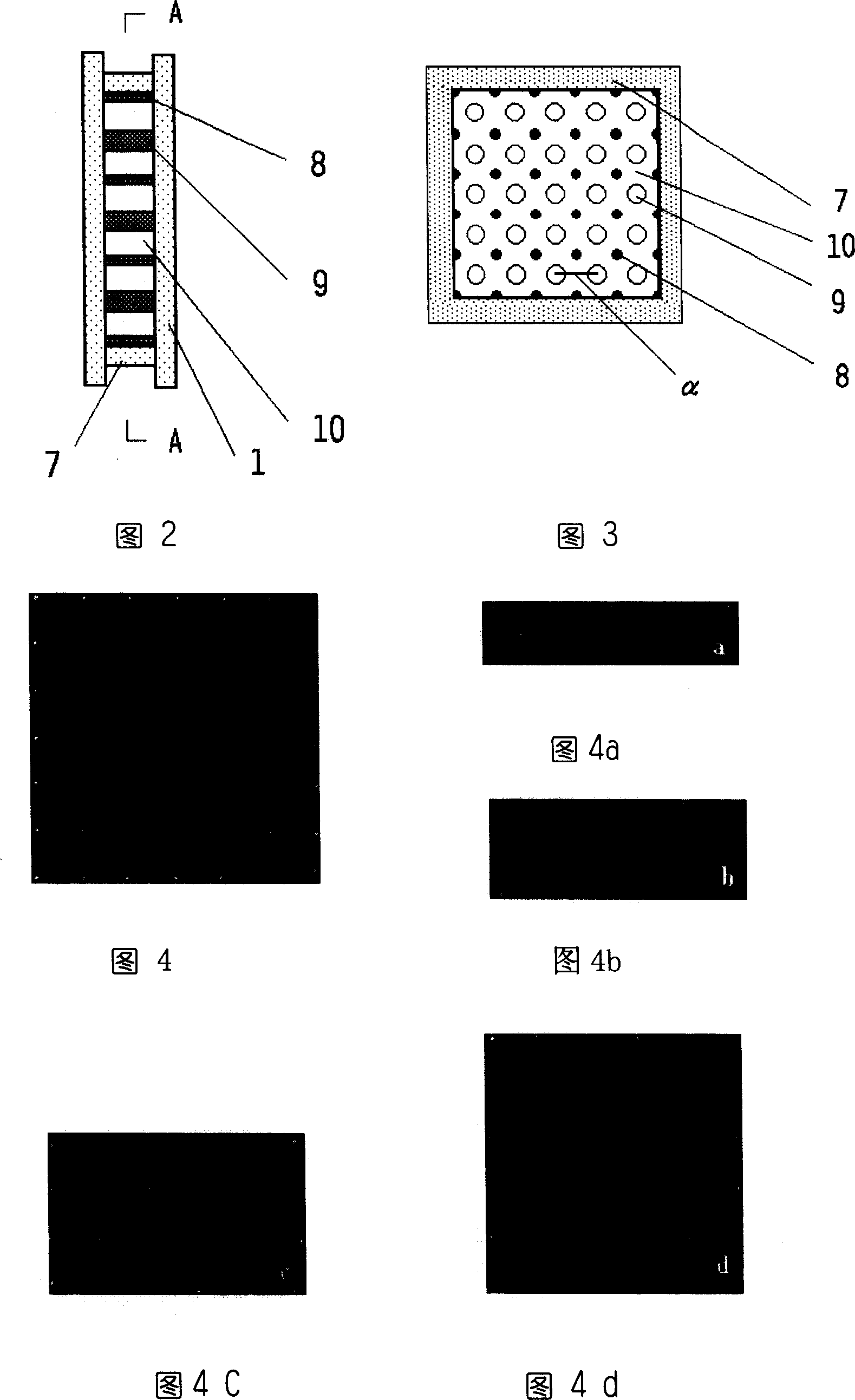

[0031] The manufacturing method of the water electrode dielectric barrier discharge device shown in Fig. 1 of the present invention is to seal the flat transparent dielectric end surface 1 and the hollow tubular dielectric cylinder surface 2 together with silica gel to make two symmetrically arranged dielectric containers, and inject water through the small hole 3 Fill the sealed space with water or other liquids, set a discharge gap 6 between the two containers, seal argon, helium, a mixture of argon and air in the cavity, and connect the high-voltage end and the ground end of the high-voltage power supply to the container respectively. The electrode leads 4 of the two water electrodes provided are connected. The length of the discharge gap 6 can be adjusted by the thickness of the discharge gap boundary 7 . As the applied voltage increases, the gas in the air gap is broken down to form a discharge, which appears as many bright discharge filaments. When the voltage frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com