Method and device for processing biological full degradation starch packing material and product thereof

A technology for packaging products and packaging materials, applied in the field of biodegradable starch packaging materials and their processing, can solve problems such as not meeting the needs of the market, and achieve the effects of clear signs, clean production sites, and short cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Example 1: The biodegradable starch packaging material is composed of the following raw materials: 70% starch, 4% viscose staple fiber, 8% pulp board, and 18% additives. Mix the raw materials in the above ratio, add water, the ratio of water to raw materials is 52:48, stir evenly, put it into a storage tank for standby. The material in the storage tank is injected into the heated mold with an injection gun, and it is made by foam molding. The additives include 70% of asbestos powder, 20% of glycerin and 10% of liquid paraffin.

Embodiment 2

[0046] Example 2: The biodegradable starch packaging material is composed of the following raw materials: 80% starch, 3% viscose staple fiber, 6% pulp board, and 11% additives. Mix the raw materials in the above ratio, add water, the ratio of water to raw materials is 52:48, stir evenly, put it into a storage tank for standby. The material in the storage tank is injected into the heated mold with an injection gun, and it is made by foam molding. The additives include 70% of asbestos powder, 20% of glycerin and 10% of liquid paraffin.

Embodiment 3

[0047] Example 3: The biodegradable starch packaging material is composed of the following raw materials: 76% starch, 3.4% viscose staple fiber, 7.2% pulp board, and 13.4% additive. Mix the raw materials in the above ratio, add water, the ratio of water to raw materials is 52:48, stir evenly, put it into a storage tank for standby. The material in the storage tank is injected into the heated mold with an injection gun, and it is made by foam molding. The additives include 70% of asbestos powder, 20% of glycerin and 10% of liquid paraffin.

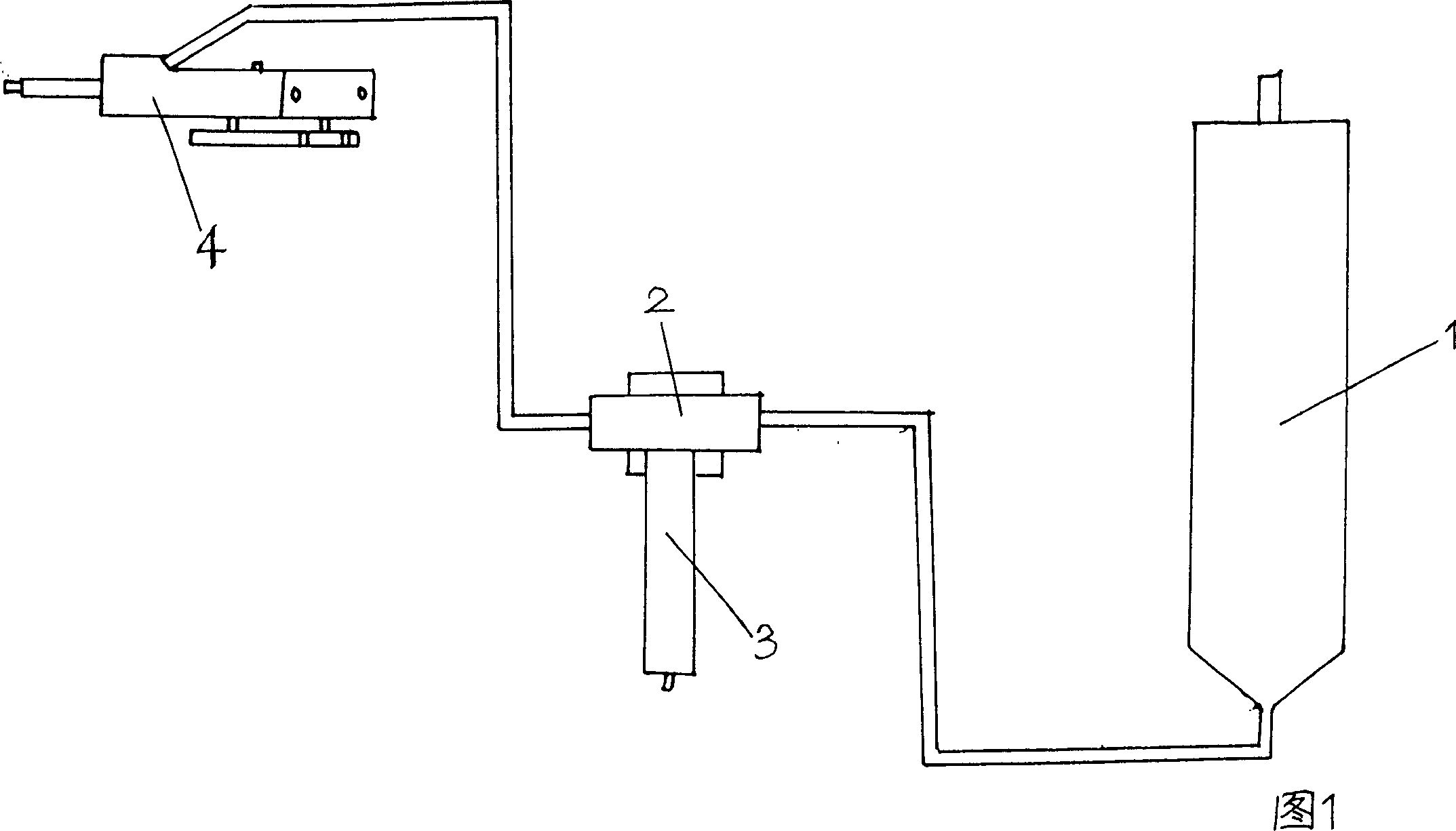

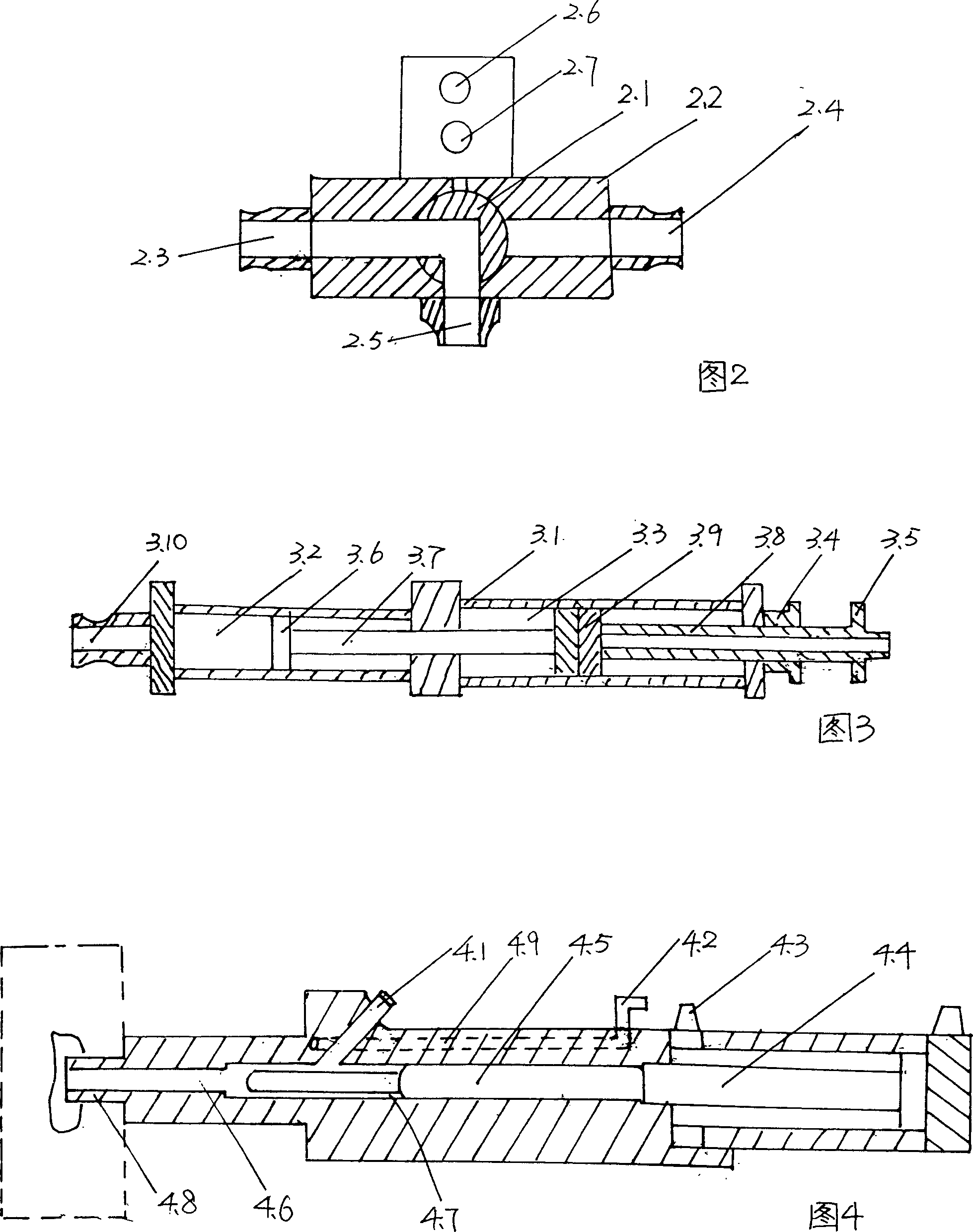

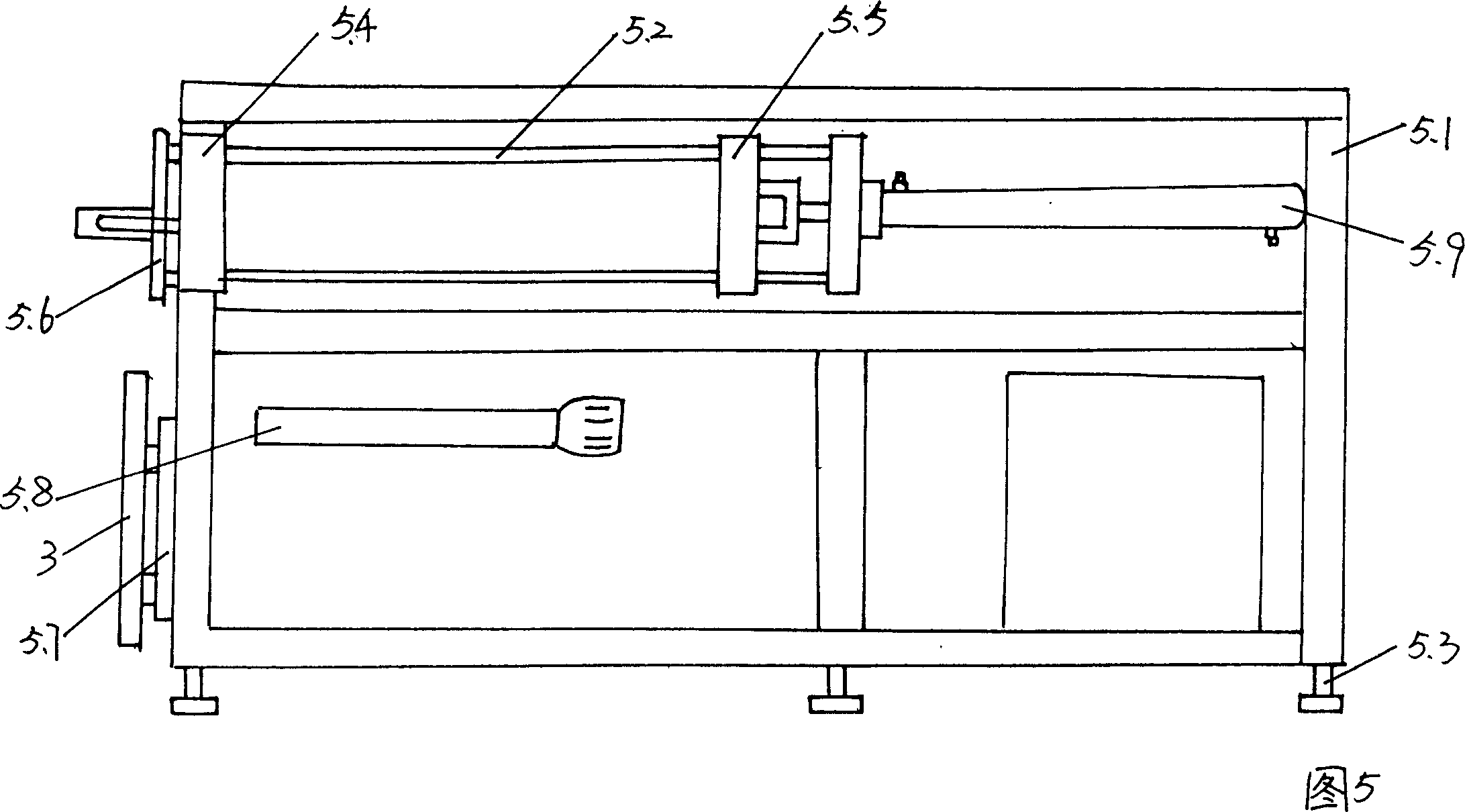

[0048] The manufacturing equipment for implementing biodegradable starch packaging materials and products according to the present invention includes a storage tank 1, a metering pump 3, an injection molding gun 4, a special injection molding machine (mainly composed of a frame 5.1, a horizontal hydraulic press 5.9, a pneumatic reversing feeder) material valve 2 and hydraulic, pneumatic and electrical control systems).

[0049] The top of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com