Method and device for producing and storing tows

A technology of tow and monofilament, which is applied in the field of devices according to the preamble of claim 9, can solve the problems of unsuitability for the processing process of the fiber production line, changes in the number of monofilament bundles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

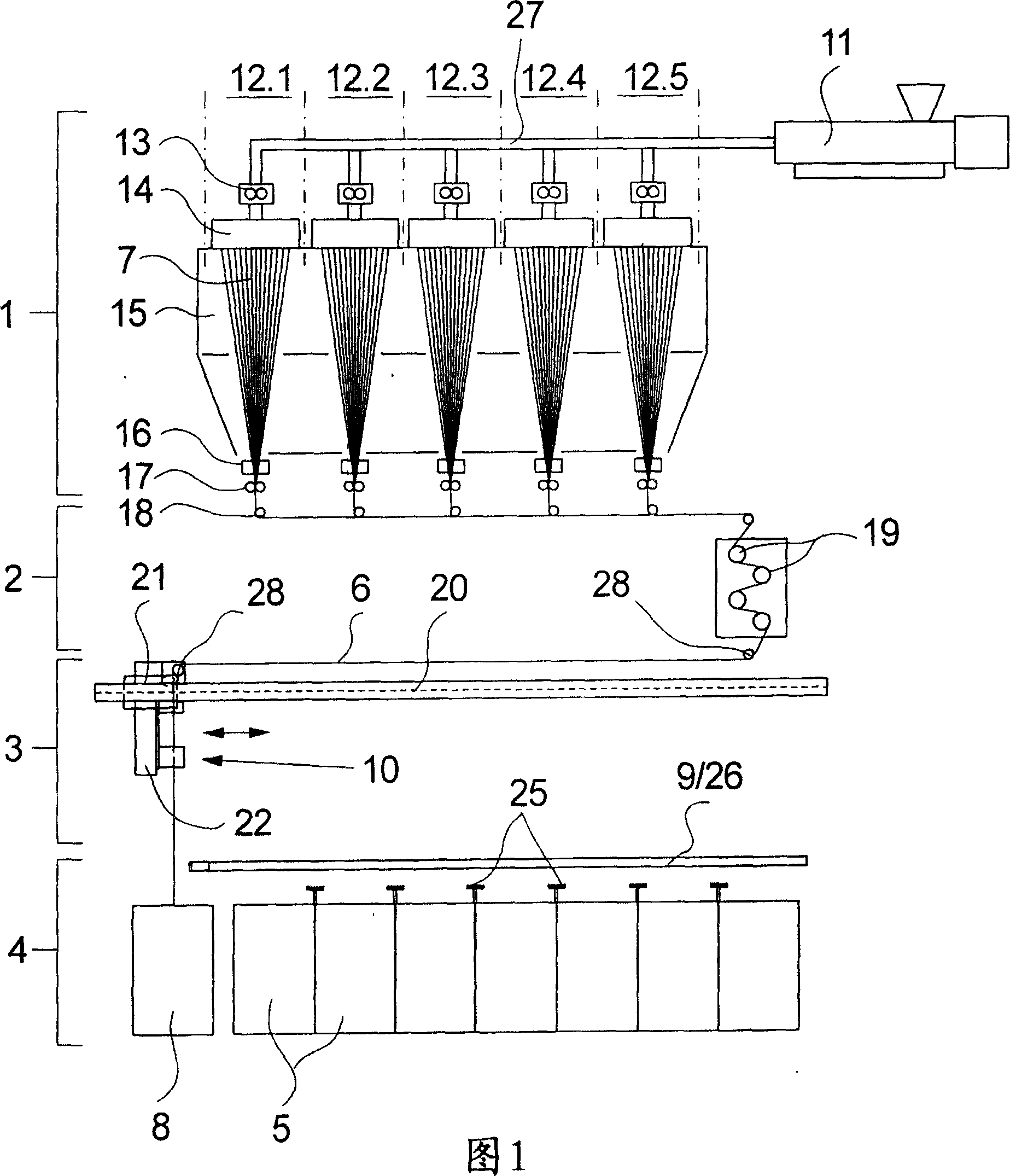

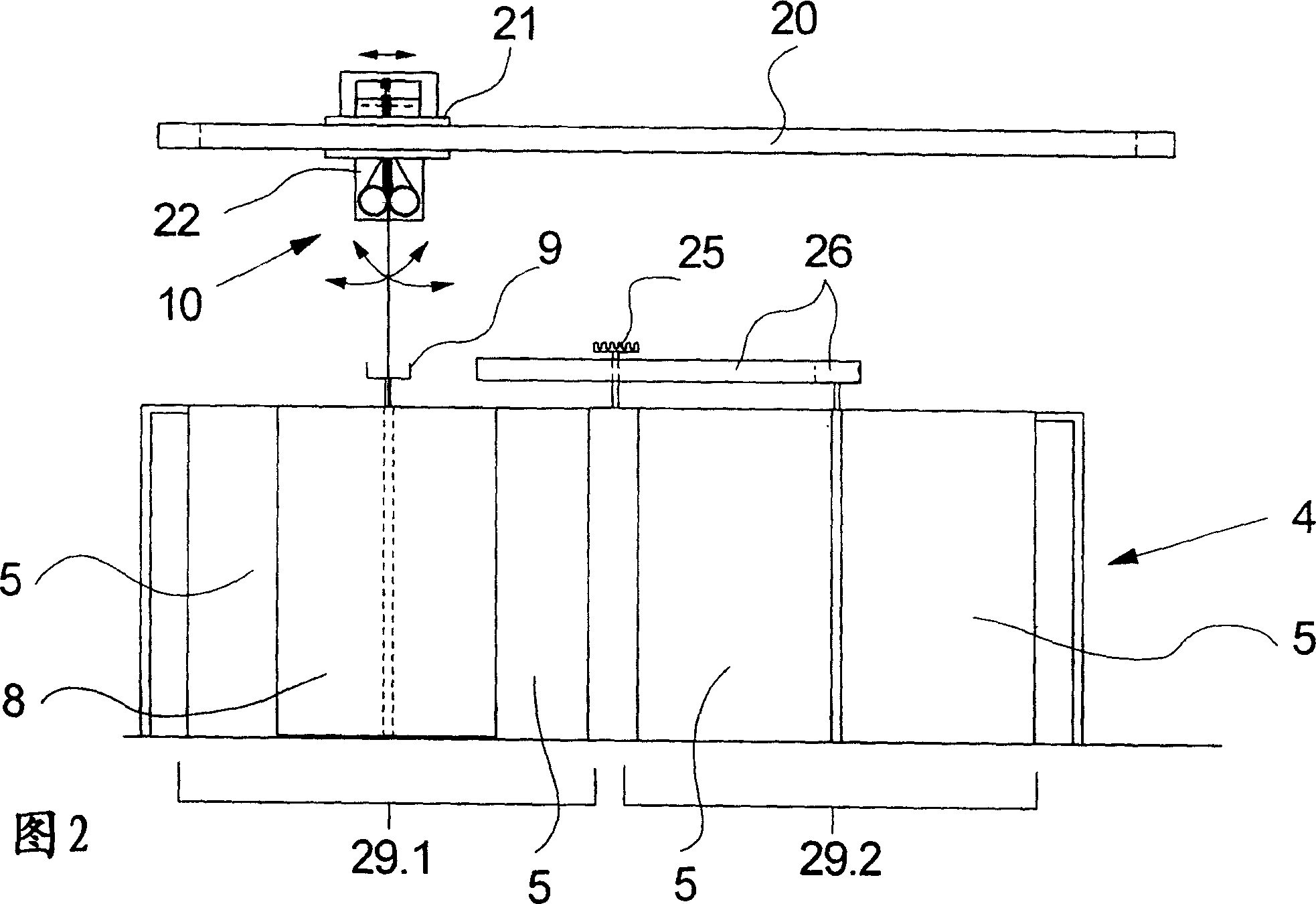

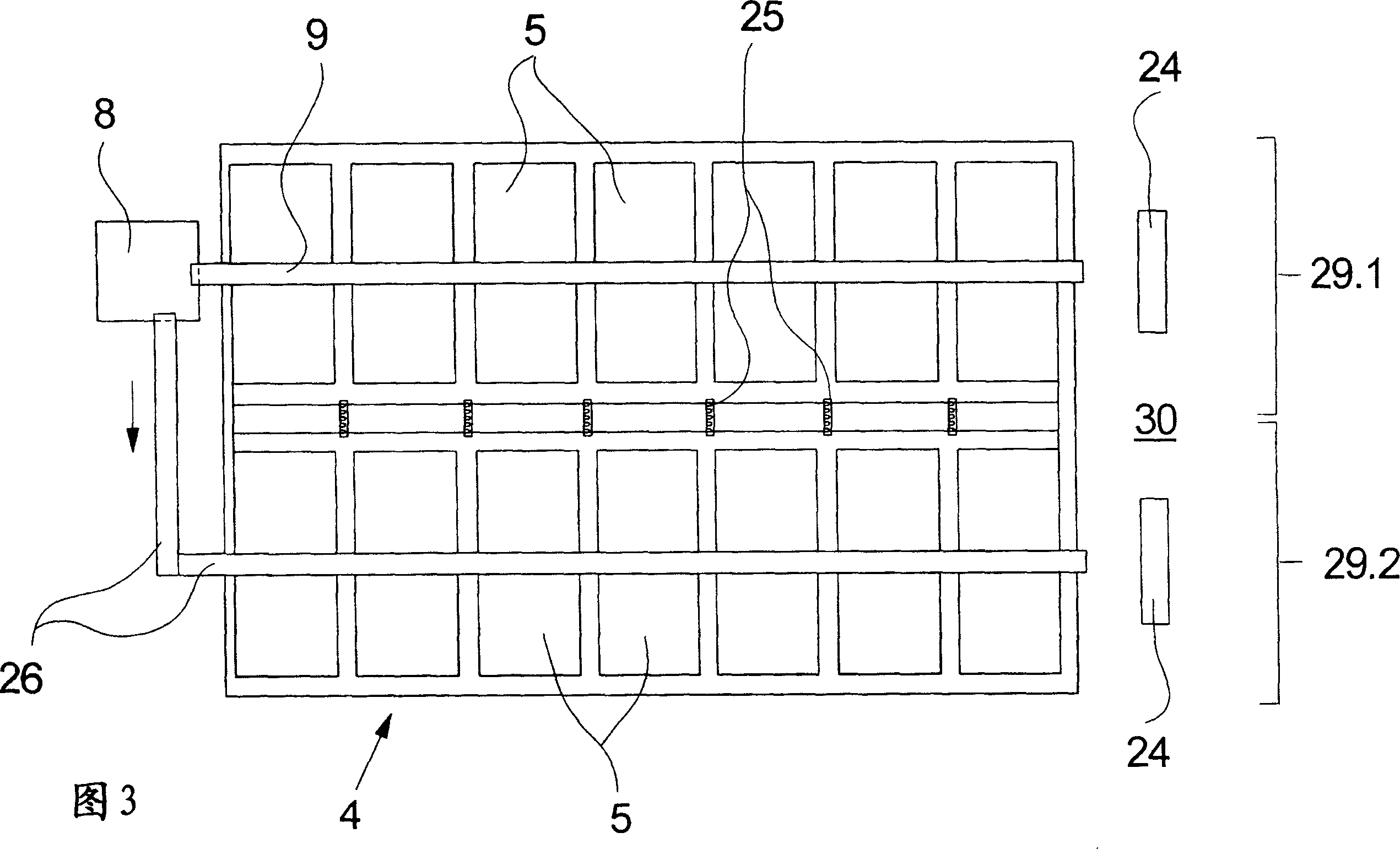

[0030] A first embodiment of the device according to the invention for carrying out the method according to the invention is schematically represented in FIG. 1 .

[0031] The device has a spinning device 1, a drawing device 2, a laying device 3 and a creel 4, which are arranged in layers relative to one another. The can creel 4 arranged on the lowermost level has a plurality of cans 5 which are alternately filled with tow 6 by means of a depositing device 3 arranged movably above the can creel 4 . For the melt spinning of a large number of monofilament bundles which are combined into a tow, the spinning device 1 comprises a plurality of spinning positions. In the exemplary embodiment according to FIG. 1, five spinning positions 12.1 to 12.5 are shown by way of example. The number of spinning positions is exemplary. Spinning units of this type may have 20, 30 or more spinning positions for making tows. Each spinning position has a spinning pump 13, which is connected via a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com