Crimple eliminating machine for cylindrical shape knitting cloth

A cylindrical and wrinkling machine technology, which is applied in the direction of setting/elongation circular fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of complex structure of smoothing finishing machines, affecting product appearance quality, and cloth quality, etc., to achieve Simple structure, reasonable design, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

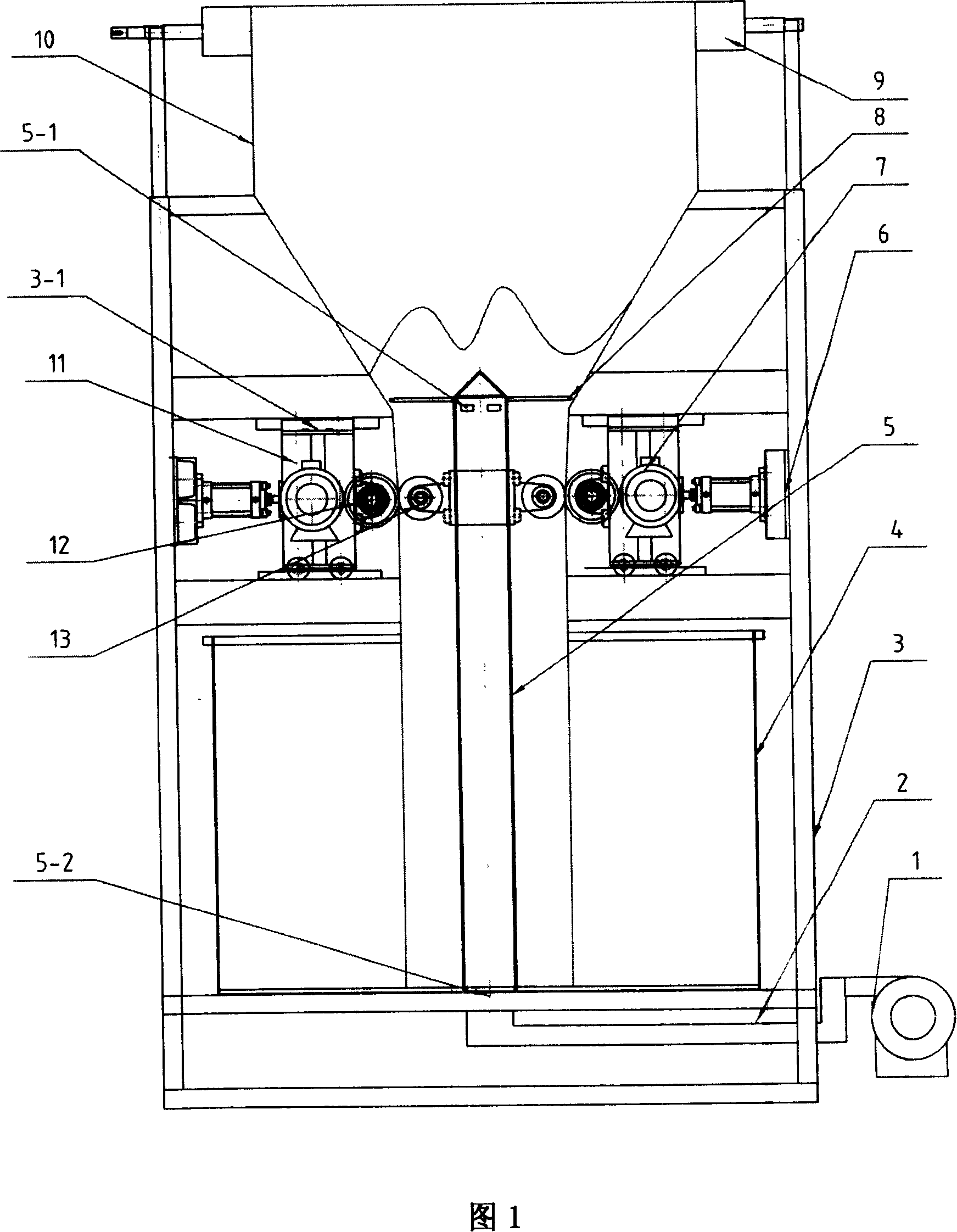

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0014] The present invention includes: frame 3, motor 7, motor frame 11, driving pressure roller 12, driven pressure roller 13, fan 1, air duct 2, cloth guiding roller 9, ventilation pipe 5, cloth support frame 8 and cloth bucket 4 The upper end of the frame 3 is equipped with a cloth-leading roller 9 through a bearing, and the cloth-leading roller 9 can introduce the cloth 10 to be sorted into the machine, and it can rotate with the friction force generated by it and the cloth 10; The bottom is provided with a cloth bucket 4, and the inside of the cloth bucket 4 is concentrically provided with a ventilation pipe 5, and the bottom air inlet 5-2 of the hollow ventilation pipe 5 communicates with the fan 1 through the air duct 2; the upper end of the ventilation pipe 5 is sealed, and the upper end side The wall is provided with several air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com