High-speed measuring device for thickness of homogeneous material light penetrated thin plate

A technology for measuring devices and thin plates, applied in measuring devices, optical devices, optics, etc., to achieve the effect of low cost, simple structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

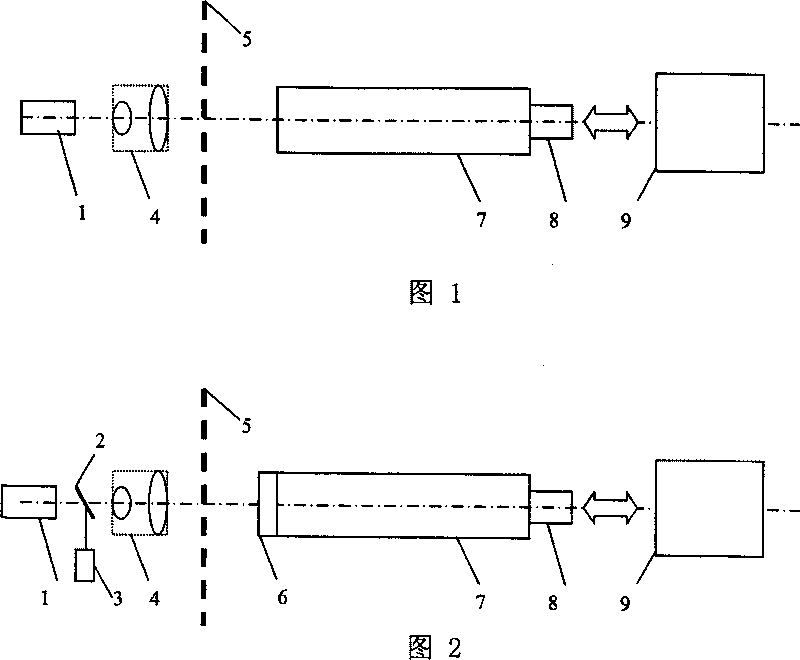

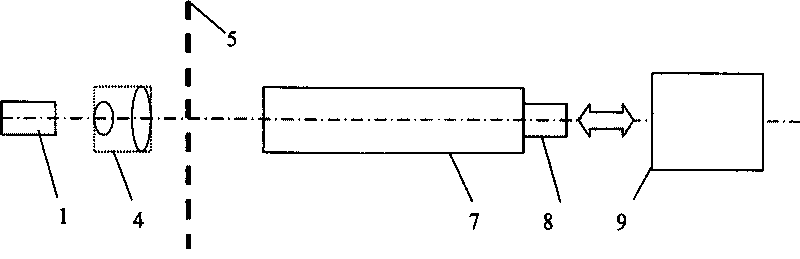

[0025] Such as figure 1 Shown embodiment 1 of the present invention, it comprises controller 9 and laser device 1, beam expander 4, spatial filter 7, photoelectric sensor 8 that are positioned on the same optical path successively; The output terminal of photoelectric sensor 8 and the input of controller 9 end connection. The measured thin plate 5 is placed between the beam expander and the spatial filter, and the optical absorption coefficient of the light-transmitting thin plate is uniform.

[0026] In this embodiment, a He—Ne laser or a semiconductor laser with a power of mW level and a wavelength of λ=0.6328 μm is used. The diameter D of the center area of the beam expander 4 is 14 mm; the length L of the spatial filter 7 is 100 mm, the aperture d is 10 mm, and the coaxiality is ≤0.3 mm (3%d).

[0027] The laser beam forms a relatively uniform plane wave through the beam expander 2, the diameter of the central area where the light intensity is basically the same D = 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com