Contact surface positive pressure varying piezoelectric rotating driver

A rotary drive, positive pressure technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the complex control circuit of asymmetric wave signals, change friction Force and other problems, to achieve the effect of large stroke drive, small movement influence, and simple drive circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

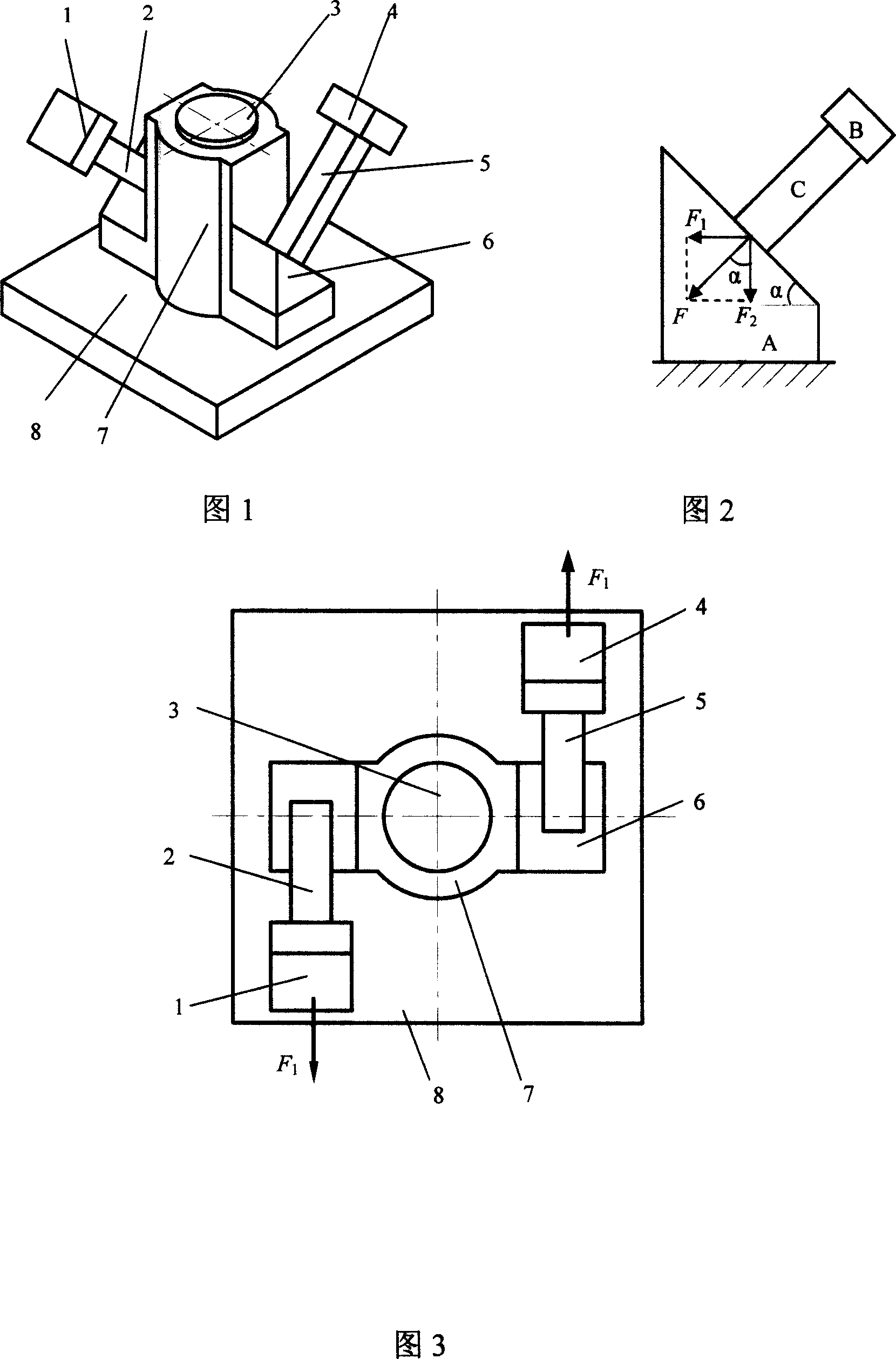

[0014] The shaft 3 is fixedly connected to the driver base 8, the shaft sleeve 7 is connected to the base 8 in rotation, the shaft sleeve 7 rotates around the geometric center of the shaft 3, and the ends of the piezoelectric stack 1 2 and the piezoelectric stack 2 5 are respectively bonded to the adjustment triangular block 6 On the inclined surface, the other end is respectively bonded with the inertial mass block 1 and the inertial mass block 2 4, the piezoelectric stack 1 2 and the inertial mass block 1 constitute the piezoelectric stack vibrator 1, and the piezoelectric stack 2 5 is connected to the inertial mass block 1. The mass block 2 4 constitutes the piezoelectric stack vibrator 2, and the adjustment triangular block 6 is fixedly connected with the driving platform on the shaft sleeve 7. The piezoelectric stack vibrator 1 and the piezoelectric stack vibrator 2 are arranged symmetrically at 180°, and installed in reverse. And it is the same as the included angle α of ...

Embodiment 2

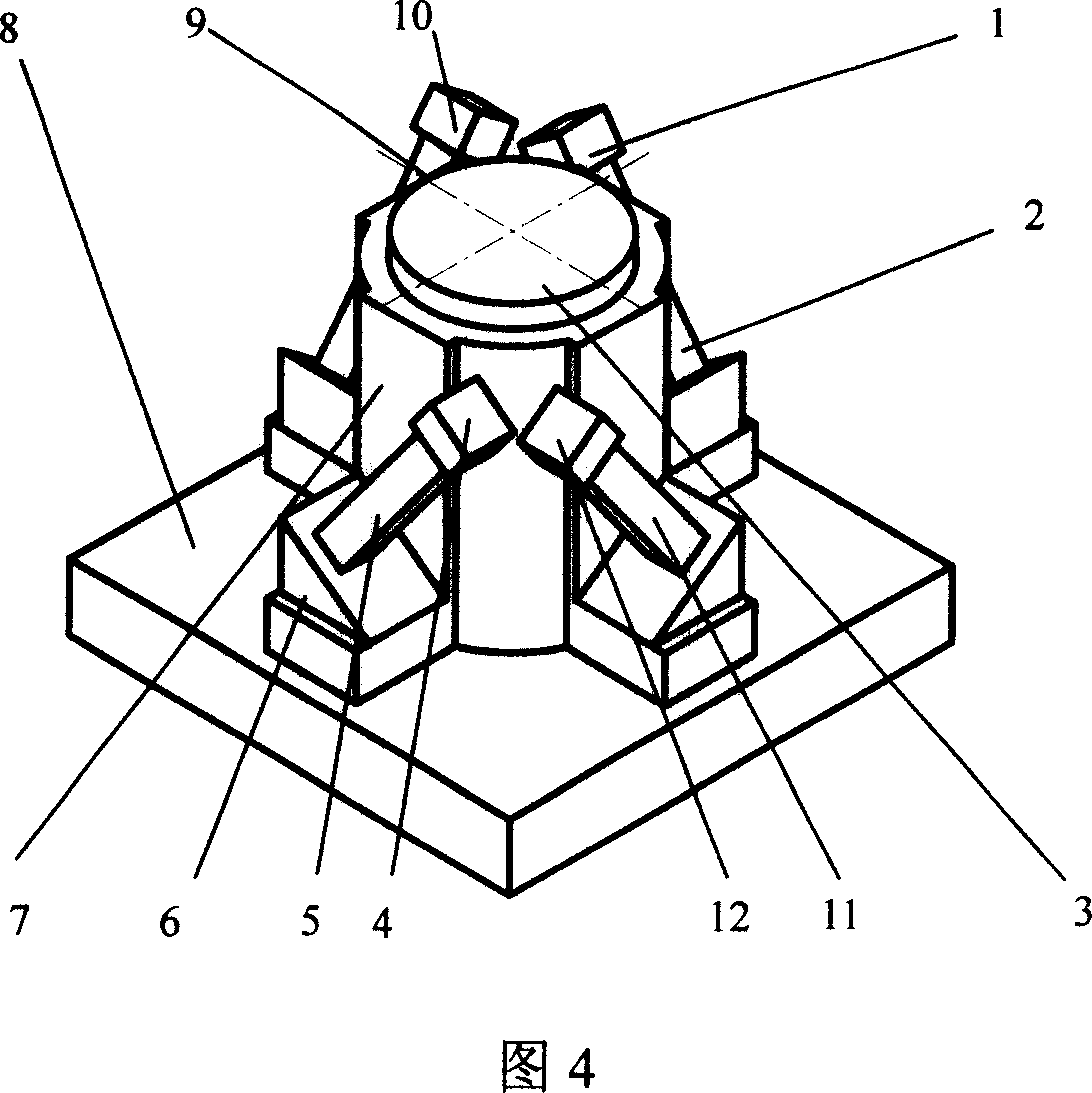

[0020] As shown in Figure 4. The shaft 3 is fixedly connected to the driver base 8, the shaft sleeve 7 is rotationally connected to the base 8, the shaft sleeve 7 rotates around the geometric center of the shaft 3, and the ends of the piezoelectric stack 1 2 and the piezoelectric stack 2 5 are respectively bonded to the adjustment triangular block 6 On the inclined surface, the other end is respectively bonded with the inertial mass block 1 and the inertial mass block 2 4, the piezoelectric stack 1 2 and the inertial mass block 1 constitute the piezoelectric stack vibrator 1, and the piezoelectric stack 2 5 is connected to the inertial mass block 1. The mass block 2 4 constitutes the piezoelectric stack vibrator 2, and the adjustment triangular block 6 is fixedly connected with the driving platform on the shaft sleeve 7. The piezoelectric stack vibrator 1 and the piezoelectric stack vibrator 2 are arranged symmetrically at 180°, and installed in reverse. And it is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com