Clathrate of chloramine phosphate and cyclodextrin or its derivative and the prepn process

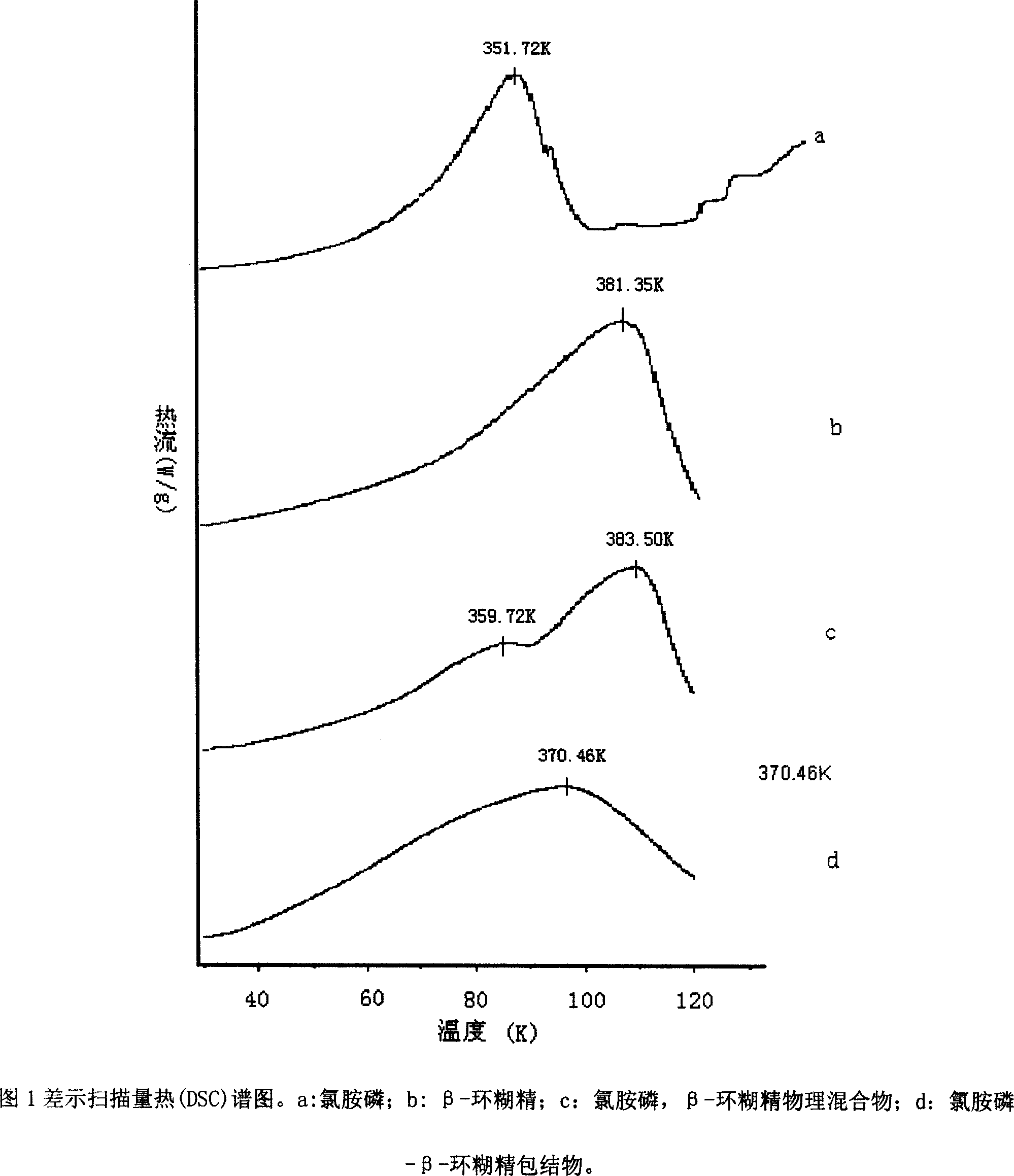

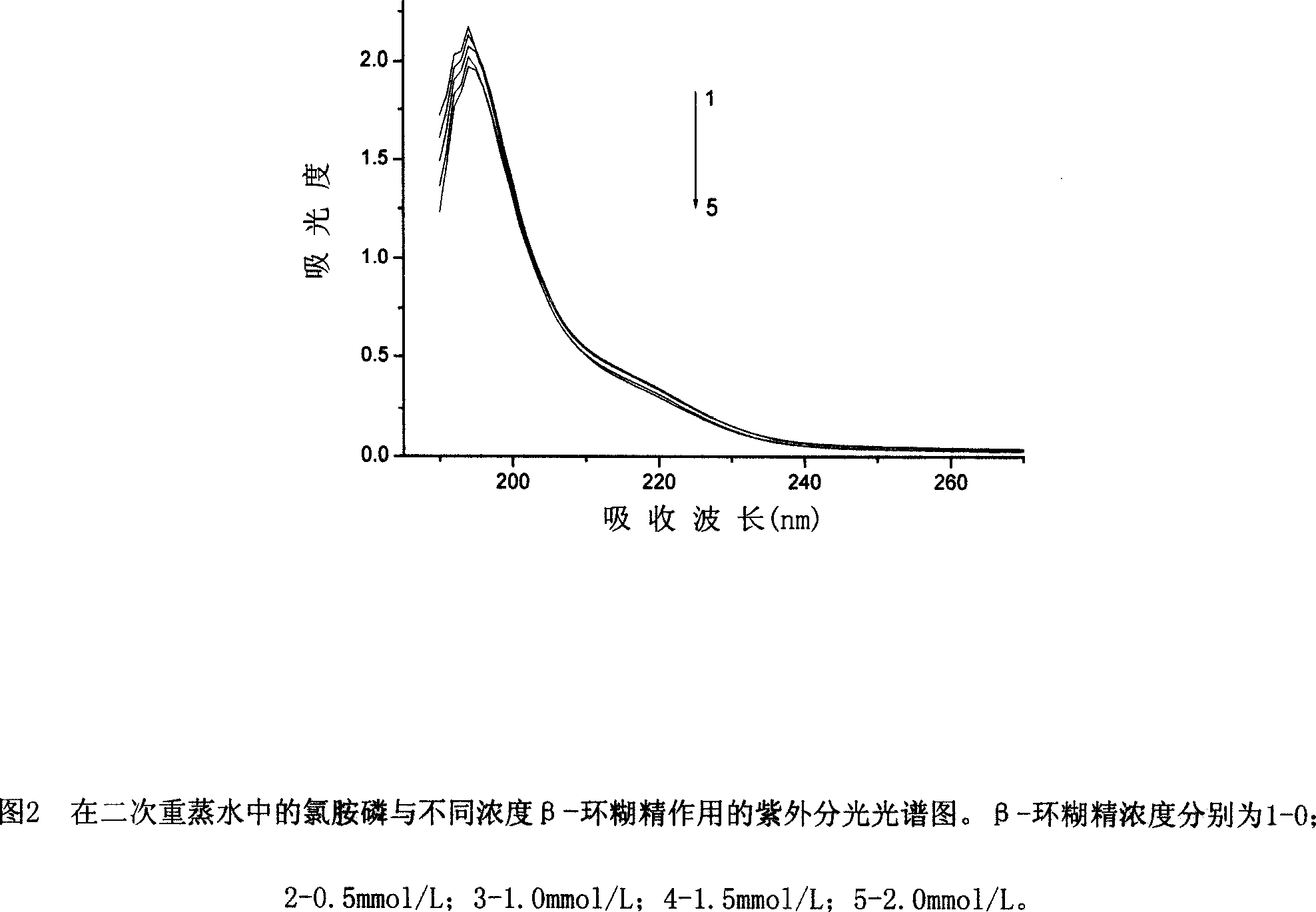

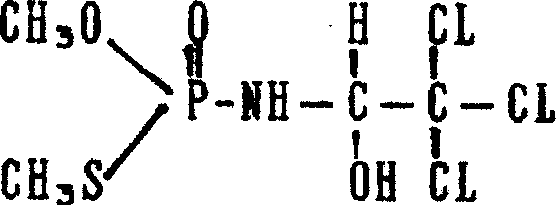

A cyclodextrin and derivative technology, which is applied in the field of inclusion complexes formed by chloramidophos and cyclodextrin or cyclodextrin derivatives and its preparation, can solve problems in the preservation of unfavorable pesticides, the prevention and control of pests, the decomposition of samples, and the Thermal decomposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take β-cyclodextrin to recrystallize twice and dry to constant weight at 110°C. Place β-cyclodextrin (1.135g, 1mmol) after drying to constant weight in a glass bowl, add a small amount of water to make it Make a paste; dissolve chloramine (577mg, 2mmol) in acetone (25ml). The acetone solution of chloramine phosphine was slowly added dropwise to the pasty cyclodextrin, and the dropwise addition was milled. The dropwise addition time was 1 hour, and after the dropwise addition was completed, milled for another 1 hour. After the milling is completed, the resulting product is placed in an oven and dried at 30°C for at least 3 hours. A small amount of organic solvent is used to remove the unincorporated chloramine, and the inclusion compound of chloramine and β-cyclodextrin can be obtained, and the product is a white powder.

Embodiment 2

[0046] Take β-cyclodextrin to recrystallize twice and dry to constant weight at 110°C. Place β-cyclodextrin (1.135g, 1mmol) after drying to constant weight in a glass bowl, add a small amount of water to make it Make a paste; dissolve chloramine (1.154g, 4mmol) in methanol (25ml). The acetone solution of chloramine phosphine was slowly added dropwise to the pasty cyclodextrin, and the dropwise addition was milled. The dropwise addition time was 1 hour, and after the dropwise addition was completed, milled for another 1 hour. After the milling is completed, the resulting product is placed in an oven and dried at 30°C for at least 3 hours. A small amount of organic solvent is used to remove the unincorporated chloramine, and the inclusion compound of chloramine and β-cyclodextrin can be obtained, and the product is a white powder.

Embodiment 3

[0048] Take 2-hydroxypropyl-β-cyclodextrin and recrystallize it twice and dry it to constant weight at 110°C. Place the β-cyclodextrin (1.425g, 1mmol) dried to constant weight in a glass bowl , Add a small amount of water to make it into a paste; dissolve chloramine (1.154g, 4mmol) in acetone (50ml). The acetone solution of chloramine phosphine was slowly added dropwise to the pasty cyclodextrin, and the dropwise addition was milled. The dropwise addition time was 1 hour, and after the dropwise addition was completed, milled for another 1 hour. After the milling is completed, the resulting product is placed in an oven and dried at 30°C for at least 3 hours. A small amount of organic solvent is used to remove the unincorporated chloramine, and then dried again to obtain the inclusion compound of chloramine and 2-hydroxypropyl-β-cyclodextrin, and the product is a white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com