Efficient tobacco material conveying system

A conveying system and tobacco material technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as moisture, temperature loss, flow of people, unsmooth logistics, and long conveying time, so as to reduce the overall production cost , Conducive to three-dimensional application, reduce the effect of investment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

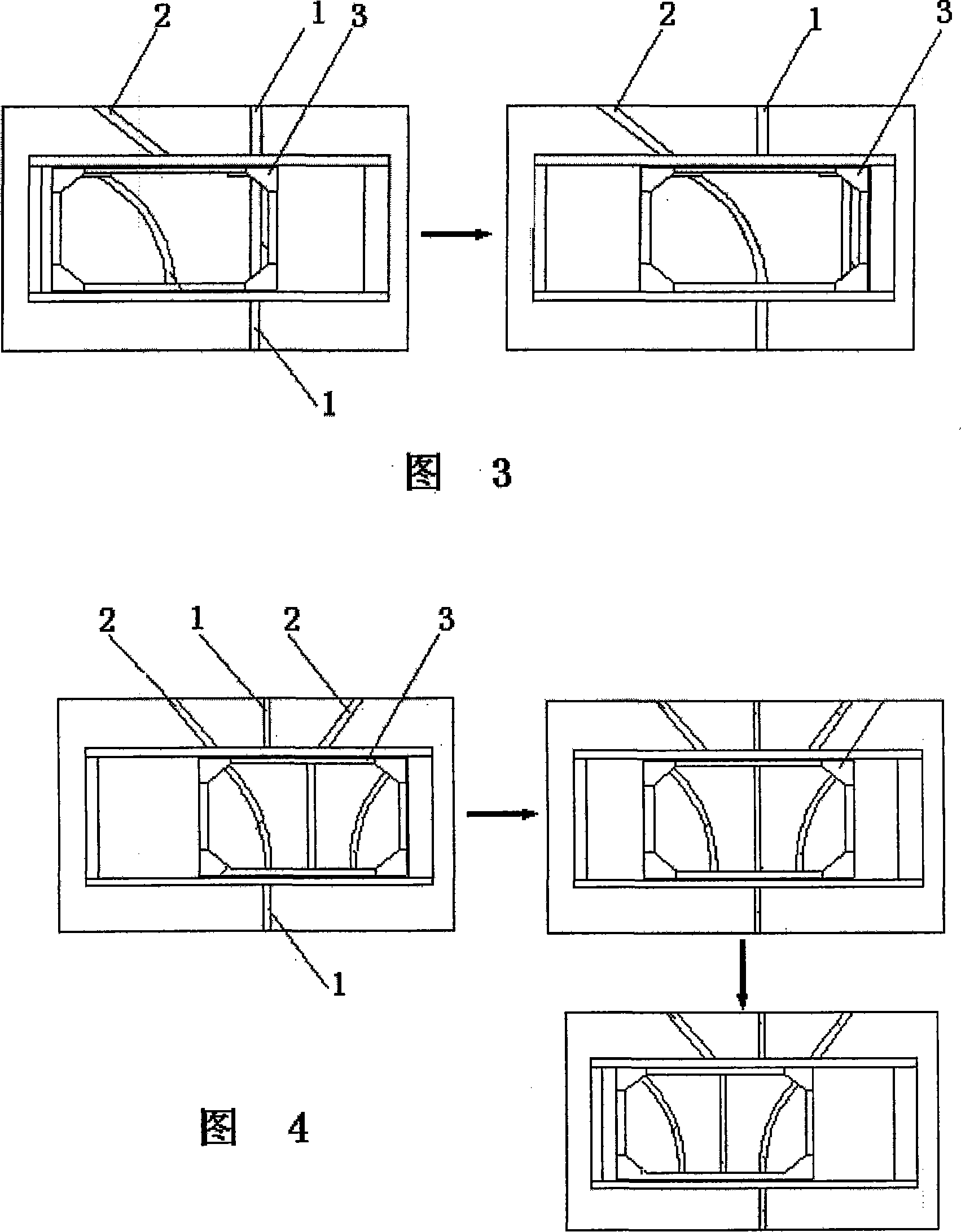

[0035] As shown in Figure 3, the guide car 5 runs along the main track 1, and the track change device 3 performs the track change operation according to the track change information sent by the control system. If the guide car 5 needs to run to the branch track 2, the track change device 3 moves To the right side, the guide car 5 runs along the arc track on the rail changing device 3 to the branch line track 2 required by the system; 8 runs to the main line track 1 to realize the two-way rail-changing operation of the guide car 5.

Embodiment 2

[0037] As shown in Figure 4, the diversion vehicle 5 runs along the main line track 1, and the rail changing device 3 performs the rail changing operation according to the track changing information sent by the control system. If the diversion vehicle 5 needs to run to the branch line track 2, the rail changing device 3 moves To the right side, the diversion vehicle 5 runs along the arc track on the rail changing device 3 to the branch line track 2 required by the system; when the rail changing device 3 moves to the middle position, the diversion vehicle 5 runs along the upper straight track 8 runs to the main line track 1; the track changing device 3 moves to the left, and the diversion vehicle 5 runs along the upper right circular arc track of the rail changing device 3 to the second branch line track 2, realizing the three-way movement of the diversion vehicle 5 Change track operation.

Embodiment 3

[0039] As shown in Figure 5, the diversion vehicle 5 runs along the main line track 1, and the track changing device performs a 90° rotating rail switching operation according to the track changing information sent by the control device, so that the diversion vehicle 5 runs along the upper straight track 8 of the rail changing device 3 to Mainline Track 1. It is also possible to run the diversion vehicle 5 along the main line track 1 to the upper straight track of the rail changing device 3 and pause after the track changing device 3 rotates according to the system requirements, and connect the upper straight track 8 of the rail changing device with the main line track 1 and the branch line track. Any one of the tracks in 2 is connected to realize the rotation and rail-changing operation of the diversion vehicle 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com