Angelica yellow wine and its making process

A technology for yellow rice wine and angelica, applied in the field of functional rice wine products and their manufacturing, can solve the problems of turbid wine body, poor taste of rice wine products, and low functionality of rice wine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

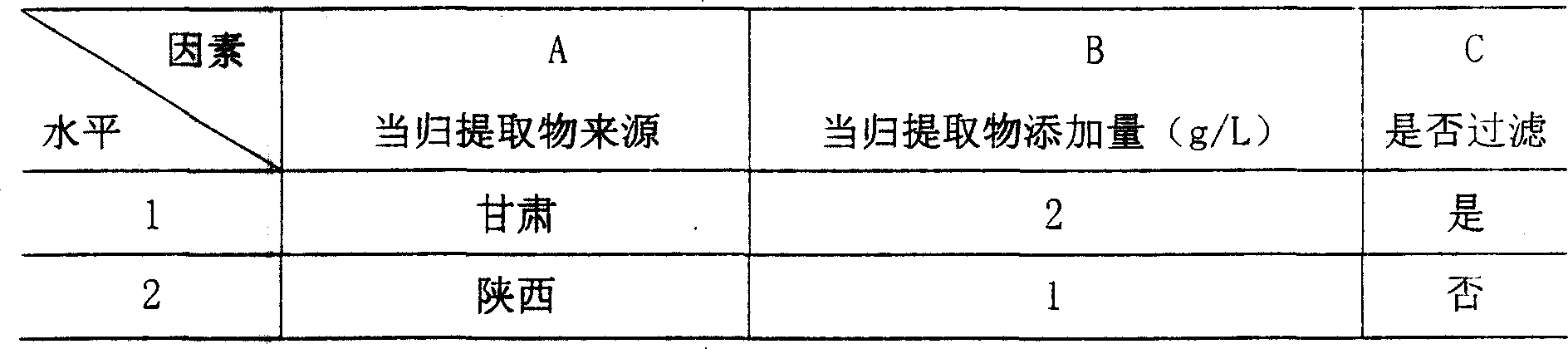

Method used

Image

Examples

Embodiment 1

[0079] The production of Angelica yellow rice wine product of the present invention mainly is made up of following steps:

[0080] (1), prepare the mature raw wine of rice wine: prepare the mature raw wine of yellow rice wine according to the basic production process of yellow rice wine.

[0081] (2), ingredients: first dissolve the Chinese angelica extract in an appropriate amount of rice wine according to the weight ratio of 0.1% of the rice wine, and then add it to the rice wine.

[0082] (3) Clarification treatment: add 8% tannin and 6% gelatin by weight to the wine liquid, control the difference in room temperature after shaking, and let it stand for 30 hours within 5°C, filter and remove the precipitate, then set aside at 60°C for 2h and 0 ℃ 24h cold and hot treatment three times, filter each time to remove the precipitate, and then freeze at -2 ℃ for 72h.

[0083] (4) Filtration: the above-mentioned yellow rice wine is respectively treated with diatomaceous earth filte...

Embodiment 2

[0100] Embodiment 2 main technology is basically the same as example 1

[0101]The production of Angelica yellow rice wine product of the present invention mainly is made up of following steps:

[0102] (1), prepare the mature raw wine of rice wine: prepare the mature raw wine of yellow rice wine according to the basic production process of yellow rice wine.

[0103] (2), ingredients: first dissolve the extract of angelica sinensis in the rice wine in a proportion of 0.2% by weight of the rice wine, and then add it to the rice wine.

[0104] (3) Clarification treatment: add 8% tannin and 6% gelatin by weight to the wine liquid, control the temperature difference of the treatment after shaking, and stand still within the range of 5°C for 48 hours, filter to remove the precipitate, and then cool it at 55°C for 2h and 0°C 24h cold and hot treatment three times, filter each time to remove the precipitate, and then freeze at -2°C for 72h.

[0105] (4) Filtration: the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com