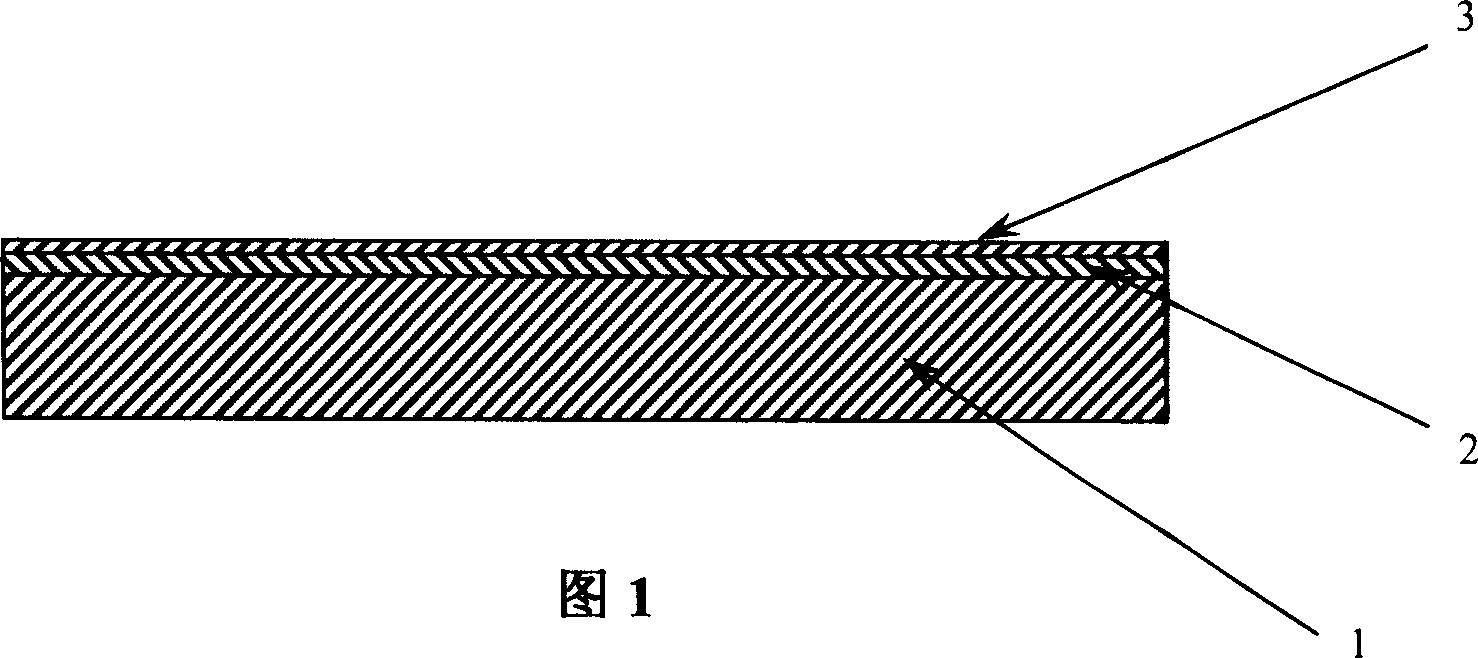

Light surface glass titanium metal planar reflector and a special glass

A surface glass and special glass technology, applied in mirrors, instruments, optics, etc., can solve problems such as glass deformation and affecting the stability of optical systems, and achieve the effects of stable surface quality, simple structure, and high reliability of assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Special glass composition is SiO 2 25wt%, PbO70wt%, Na 2 O1.2wt%, K 2 O1wt%, MgO2.0wt%, As 2 o 3 0.2wt%, of which, PbO with Pb 3 o 4 Introduce, Na 2 Na for O 2 CO 3 Introduced, K 2 O with K 2 CO 3 For introduction, MgO is introduced with basic magnesium carbonate, and the rest of the components are introduced with oxides. The introductions used analytically pure chemical reagents. Mix the raw materials well and evenly, add them into a platinum crucible with a temperature of 1260°C, melt for 10 hours, and stir to ensure good uniformity. The melt temperature is about 1050°C during casting, and the annealing temperature is 420°C. Obtain a glass blank, and then grind and polish it to make a 2mm glass plate.

[0017] Measured by industry standards, the expansion coefficient of the glass is 89×10 -7 / °C, the softening point is 460°C.

[0018] The titanium metal substrate is made of TC4 material, which is precision processed first, with a surface roughness of 1...

example 2

[0022] Special glass composition is SiO 2 40wt%, PbO5 2.5wt%, Na 2 O2.5wt%, K 2 O2.5wt%, MgO2.0wt%, As 2 o 3 0.5wt%, Pb for PbO 3 o 4 Introduce, Na 2 Na for O 2 CO 3 Introduced, K 2 O with K 2 CO 3 Introduction, MgO is introduced with basic magnesium carbonate, and the rest of the ingredients are introduced with oxides. The introductions used analytically pure chemical reagents. Mix the raw materials well and add them into a platinum crucible at a temperature of 1450°C. The melting time is 8 hours and stirred to ensure good uniformity. The melt temperature is about 1350°C during casting and the annealing temperature is 550°C. Obtain a glass blank, and then grind and polish it to make a 3mm glass plate. Measured by industry standards, the expansion coefficient of the glass is 80×10 -7 / °C, the softening point is 600°C.

[0023] The titanium metal substrate is made of TA2 material, which is precision processed first, with a surface roughness of 10 μm.

[0024] W...

example 3

[0027] Special glass composition is SiO 2 30wt%, PbO67.2wt%, Na 2 O1.5wt%, K 2 O0.5wt%, CaO0.5wt%, As 2 o 3 0.3wt%, of which, PbO with Pb 3 o 4 Introduce, Na 2 Na for O 2 CO 3 Introduced, K 2 O with K 2 CO 3 Introduced, CaO with CaCO 3 introduced, and the rest of the ingredients were introduced with oxides. The introductions used analytically pure chemical reagents. Mix the raw materials well, add them into a platinum crucible with a temperature of 1350°C, melt for 10 hours, and stir to ensure good uniformity. The melt temperature is about 1200°C during casting, and the annealing temperature is 490°C. Obtain a glass blank, and then grind and polish it to make a 3mm glass plate. Measured by industry standards, the expansion coefficient of the glass is 84×10 -7 / °C, the softening point is 520°C.

[0028] The titanium metal substrate is made of TC4 material, which is precision processed first, with a surface roughness of 15 μm.

[0029] Clean the glass and metal w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com