DC motor and dynamo

A DC motor and armature technology, applied in the direction of electric components, transmission devices, mechanical equipment, etc., can solve the problems of dispersion and consumption of the torque of the rotating shaft of the motor rotor, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

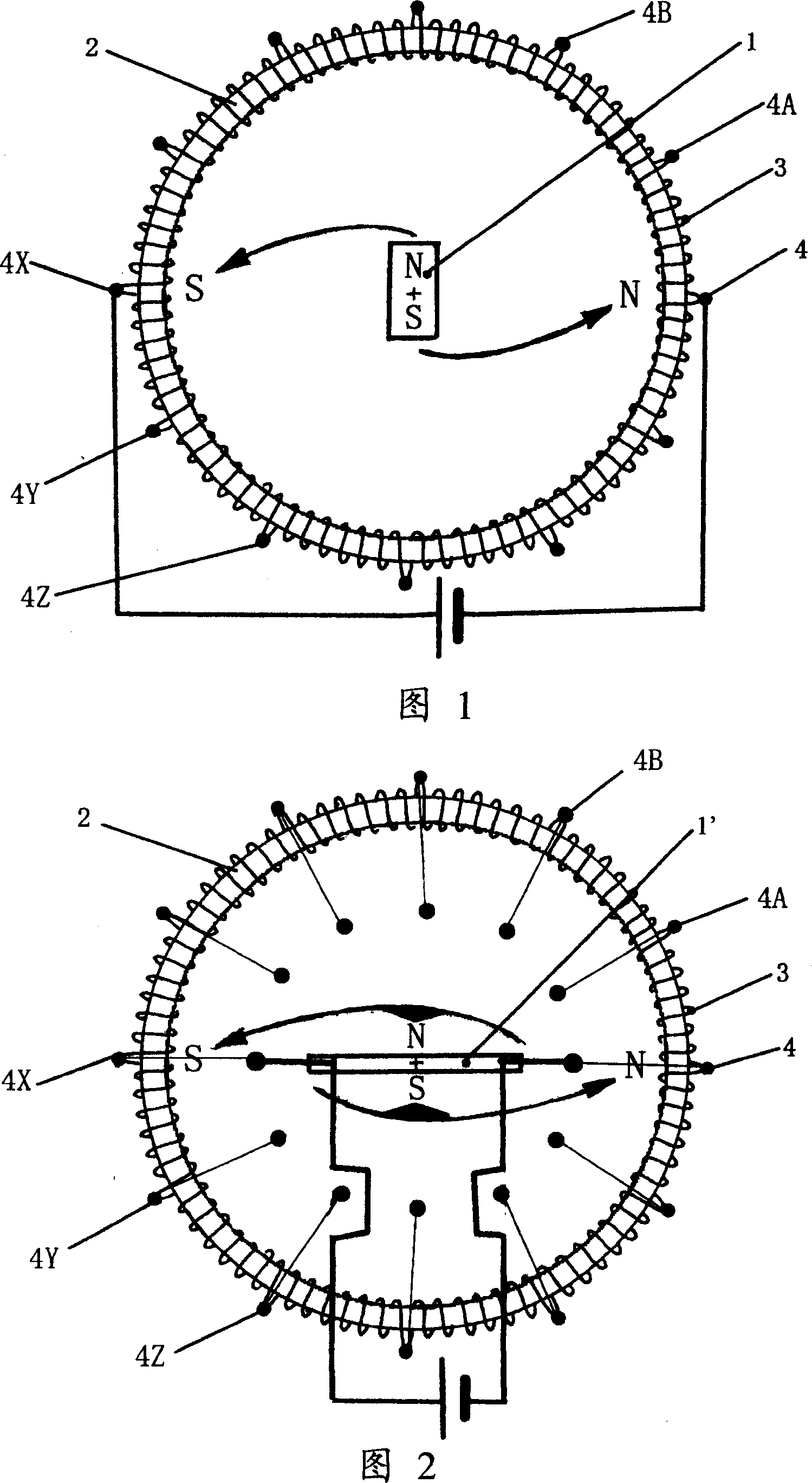

Embodiment 1

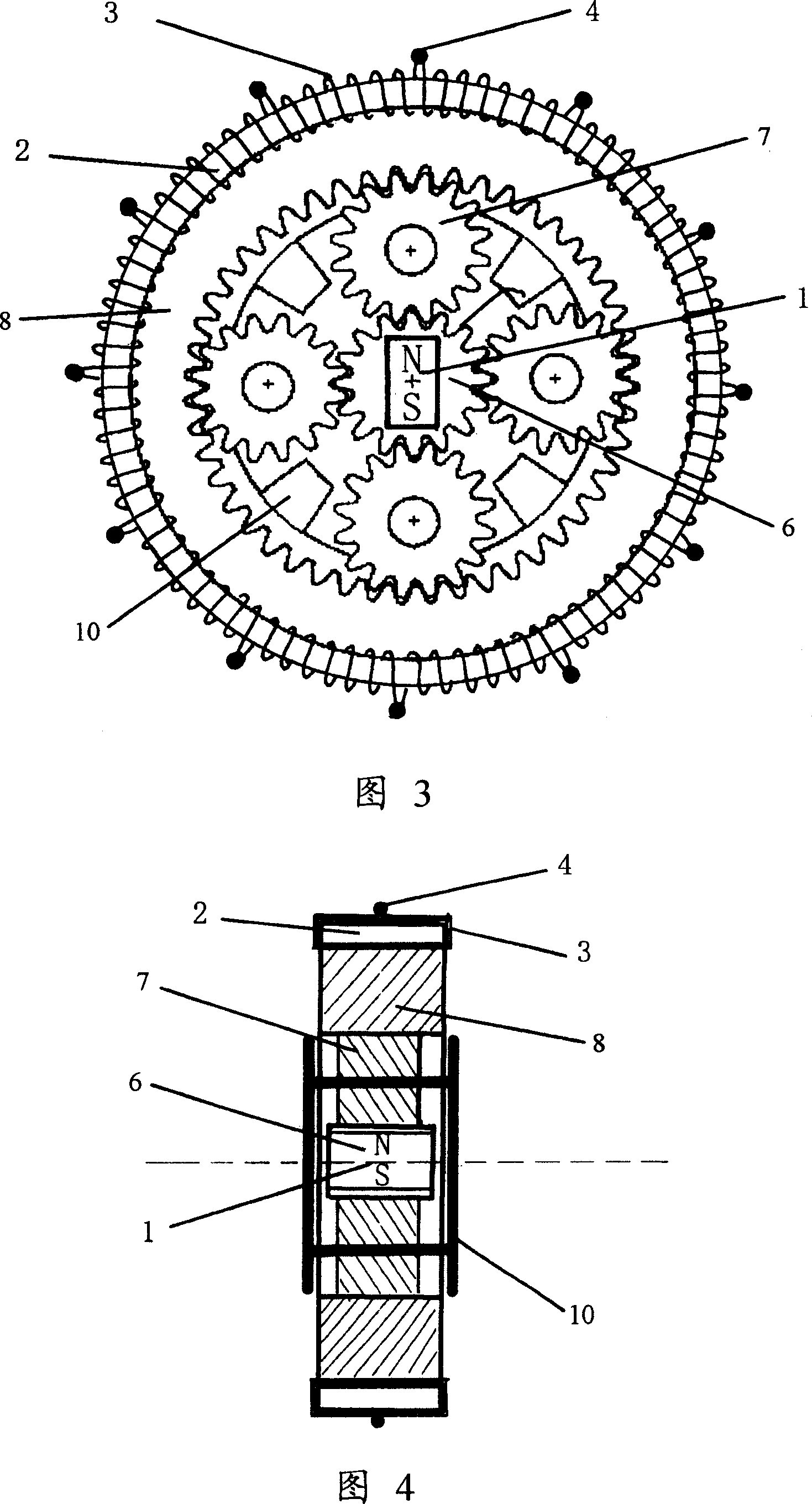

[0095] Fig. 3 is a front view of the planetary gear motor of the present invention. The permanent magnets of the two-pole inner magnet rotor 1 of the present invention are integrally provided on the sun gear 6 , and the four planetary gears 7 are held so as to mesh with the sun gear 6 . The number of planetary gears is just an example. The planetary gear 7 is rotatably held by the carrier 10 , and is held rotatably by the meshing of the internal gear 8 and the planetary gear 7 . As an example, 12 toroidal coils 3 are neatly wound around the seamless toroidal core 2 on the outer periphery of the internal gear 11, and 12 input terminals 4 are provided. The method of generating the rotational force of the sun gear 6 is the same as that of the two-pole DC motor of the present invention.

[0096] Fig. 4 is a side sectional view of the planetary gear motor of the present invention. As can be seen from this cross-sectional view, the sun gear 6, the planetary gear 7, the internal g...

Embodiment 2

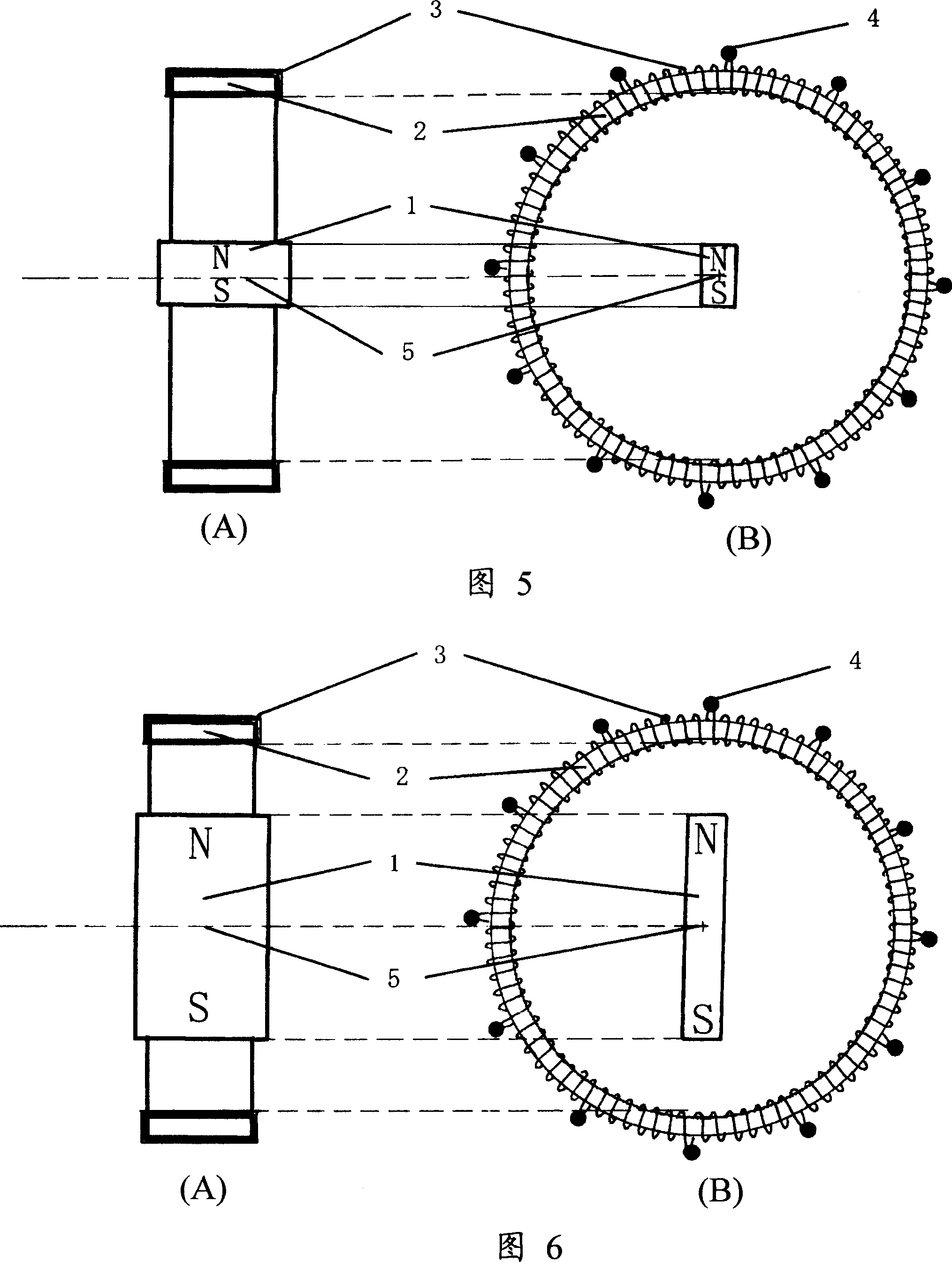

[0098] What Fig. 6 shows is that the ratio of the rotation diameter of the magnetic pole front end of the two-pole internal magnet rotor 1 of the present invention to the inner diameter of the annular iron core 2 conforms to the golden section ratio, that is, 61.80339%. The ratio of the magnetic attraction force between the poles inside the rotor 1 to the influence of the rotational torque is measured and derived from the results. What Fig. 7 shows is that the two-pole inner magnet rotor 1' of the plate magnet magnetic field is arranged according to the rotational diameter of the above-mentioned golden section ratio.

[0099] Compared with the two-pole internal magnet rotor 1 and the two-pole internal magnet rotor 1' shown in Fig. 5 and Fig. 8, the two-pole internal magnet rotor 1 and the two-pole internal magnet rotor 1' have large torque and slow rotation speed, so they are suitable for low-speed and high-speed rotation. moment.

[0100] As an example, the two-pole DC motor...

Embodiment 3

[0105] Fig. 11 and Fig. 12 are the figure that the two-pole inner magnet rotor 1 of the bar magnet magnetic field and the two-pole inner magnet rotor 1' of the plate magnet magnetic field are arranged at the armature center 5 deviated from the gapless annular iron core 2.

[0106] In the above-mentioned figures, the gap between the annular iron core 2 and the two-pole internal magnet rotor 1 or the two-pole internal magnet rotor 1' deviates as the feature of the present invention, and mechanical devices such as gears formed of non-magnetic materials can also be provided at the armature center 5.

[0107] As an example, the two-pole DC motor of the present invention is formed in the following manner, that is, the two-pole internal magnet rotor 1 having a bar magnet-type magnetic field as shown in FIG. Twelve toroidal coils 3 in which enamel copper wires with a diameter of 0.5 mm are wound 250 times are evenly arranged on the entire circumference of a toroidal iron core with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com