Clamping five level variable frequency driving device utilizing internal and external ring double-group rectifier bridge

A variable frequency drive, rectifier bridge technology, applied in the direction of AC motor control, electrical components, control systems, etc., to achieve the effect of reducing the number and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

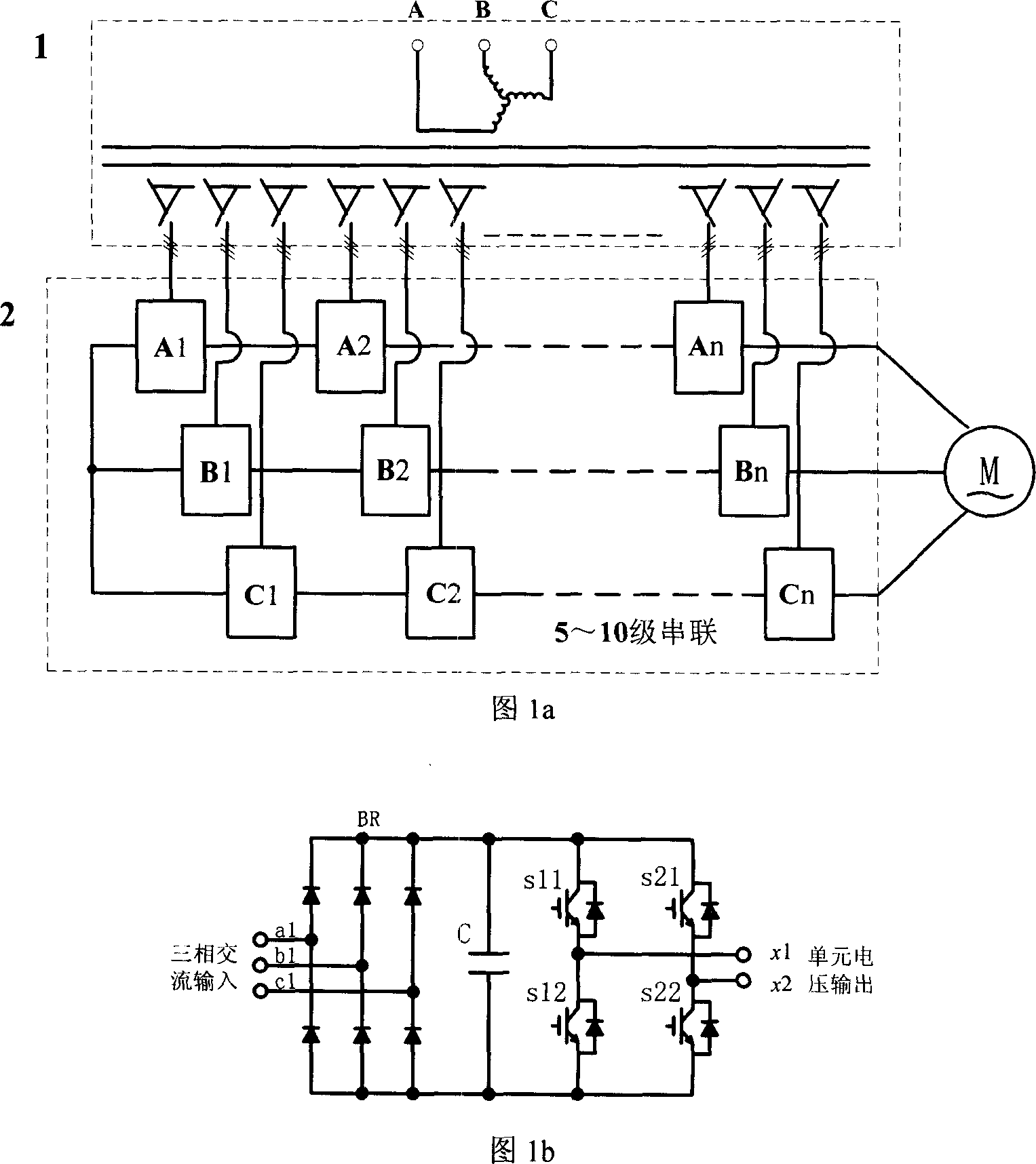

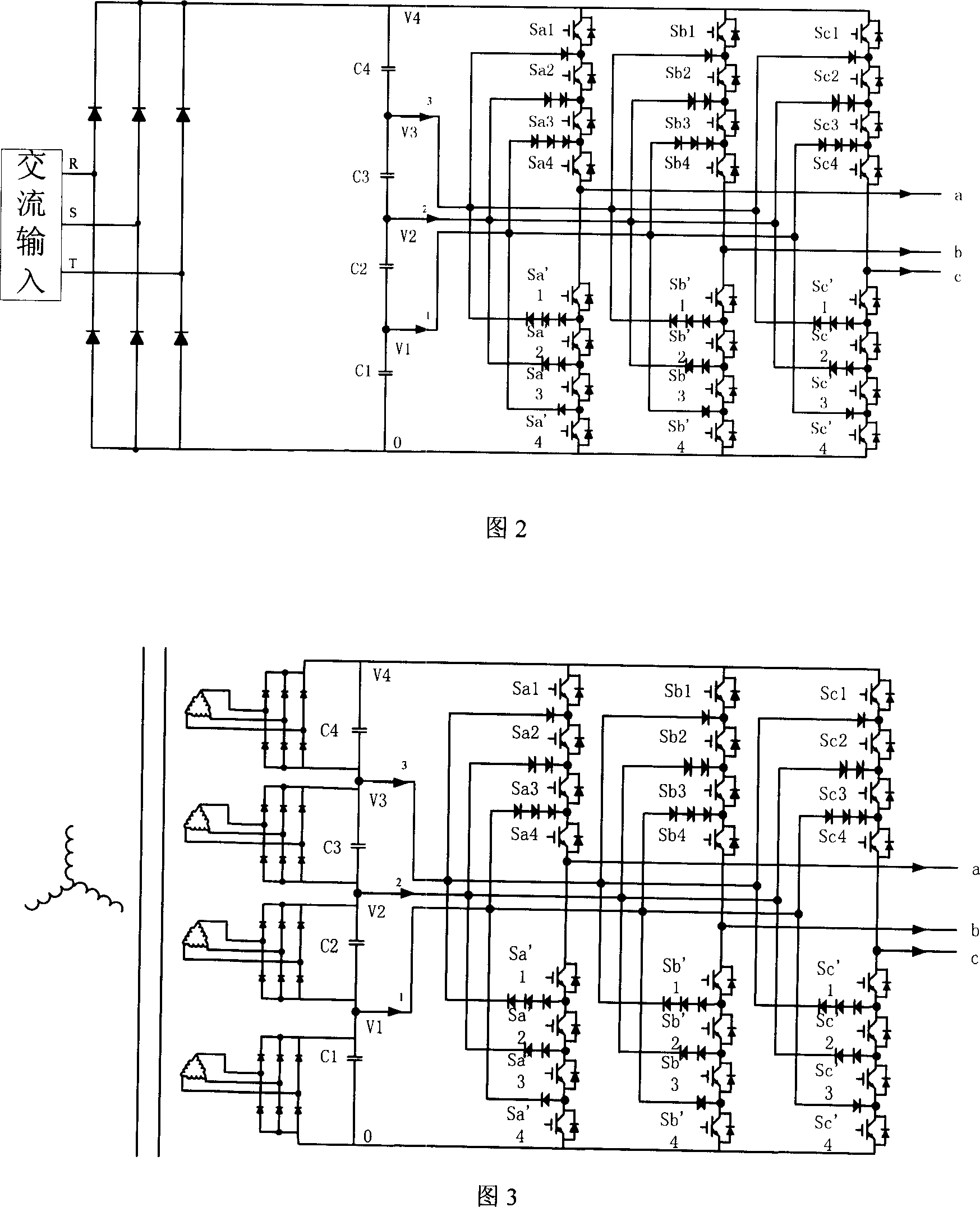

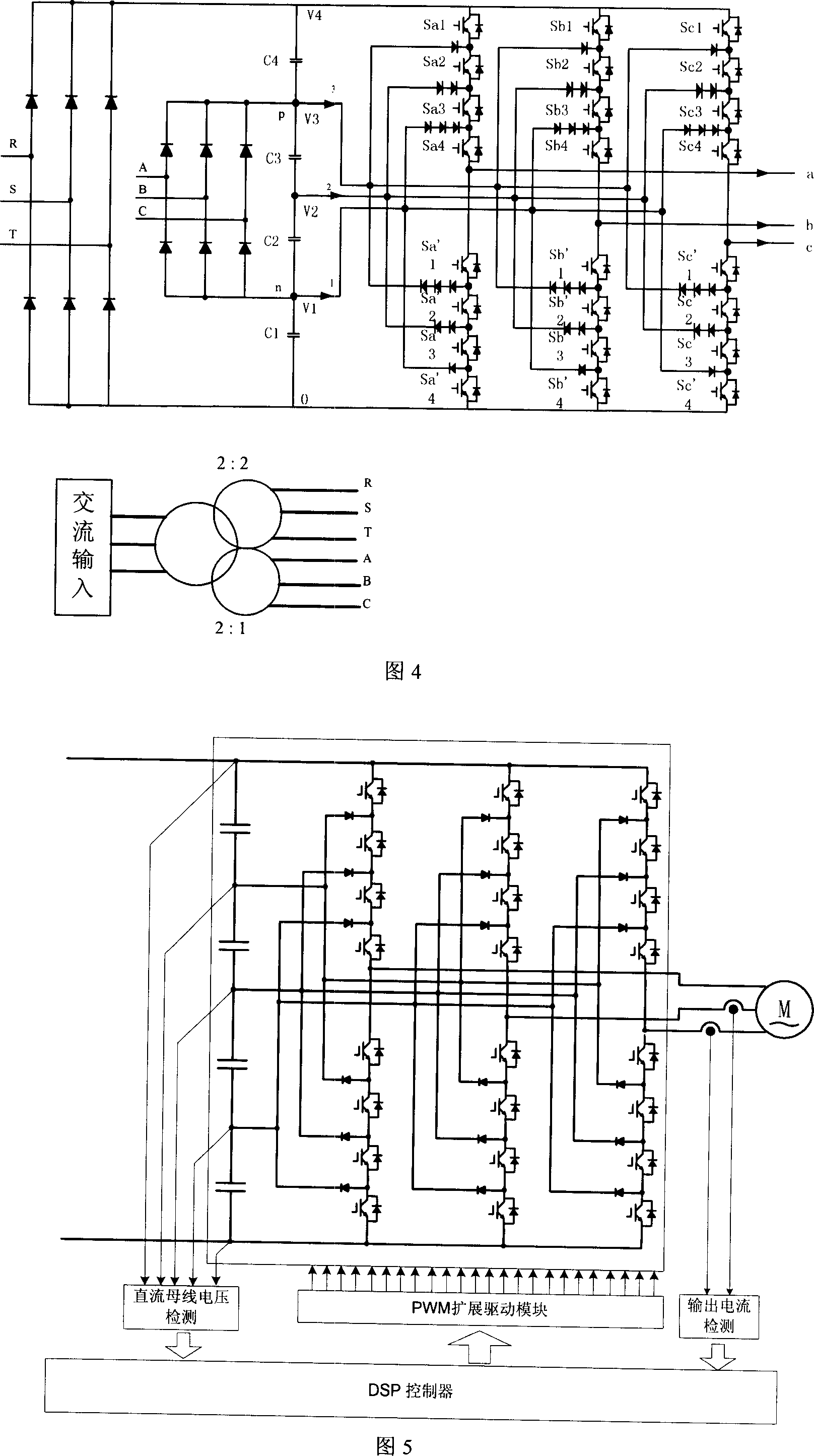

[0034] The structure of the present invention is shown in Figure 4. Two groups of rectifier bridges are respectively connected to the DC bus and the internal floating capacitors to control the voltage balance of each capacitor on the bus, thereby controlling the diode-clamped five-level inverter in the whole Stable output over load range:

[0035] The two groups of rectifier bridges are referred to below as the outer ring rectifier bridge and the inner ring rectifier bridge respectively. Both the inner and outer ring rectifier bridges are uncontrollable rectifier bridges, and the output DC voltage ratio is 1:2, that is, it is assumed that the output of the outer ring rectifier bridge is voltage is V dc , then the output voltage of the inner ring rectifier bridge is V dc / 2, so that the inner ring capacitor voltage can be guaranteed to be 1 / 2 of the total bus voltage value, which is equivalent to reducing the degrees of freedom of the bus voltage in the original five-level str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com