Thermal expansion inhibitor, zero thermal expansion material, negative thermal expansion material, method for inhibiting thermal expansion, and method for producing thermal expansion inhibitor

一种负热膨胀系数、热膨胀的技术,应用在零或负热膨胀材料,热膨胀抑制剂的制造领域,能够解决不能热膨胀抑制剂使用、相变幅度窄等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] (1) Manufacture of thermal expansion inhibitors

[0159] mn 3 A 1 N 3 and Mn 3 A 2 N(A 1 and A 2 is Mn, Co, Ni, Cu, Zn, Ga, Ge, Pd, Ag, In or Sn, the same below) is by Mn 2 N and A are Mn:A 1 or A 2 After weighing and stirring at a molar ratio of =3:1, vacuum seal the quartz tube (approximately 10 -3 torr), obtained by heating and roasting at 500-770°C for 60-70 hours. However, Mn 3 GaN is based on Mn 2 N and GaN are used as raw materials, and they are obtained by heating and roasting at 760°C for 60 hours in 1 atmosphere of nitrogen. In addition, Mn 4 N is obtained by heating and calcining metal Mn at 450°C for 120 hours under 1 atmosphere of nitrogen gas.

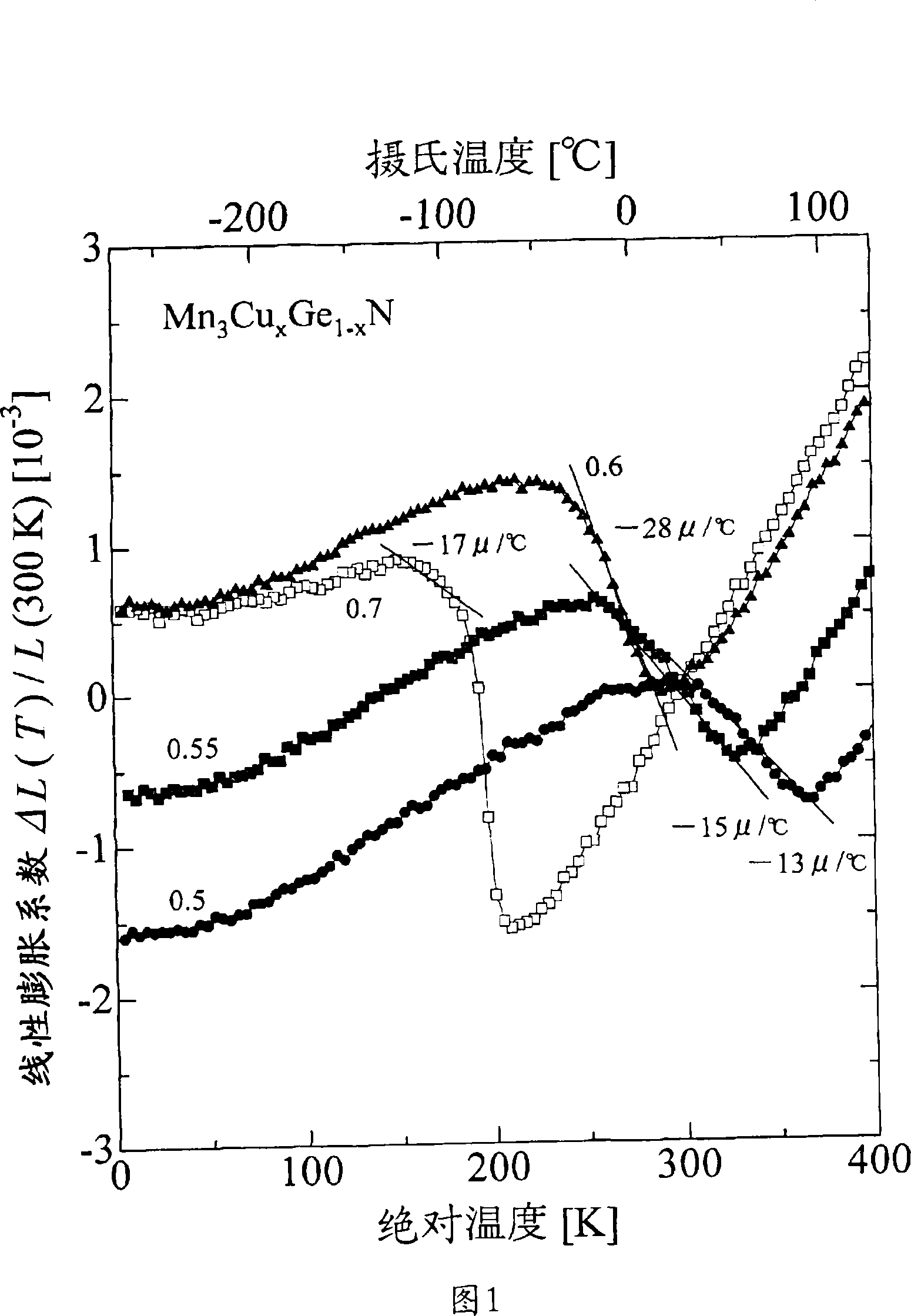

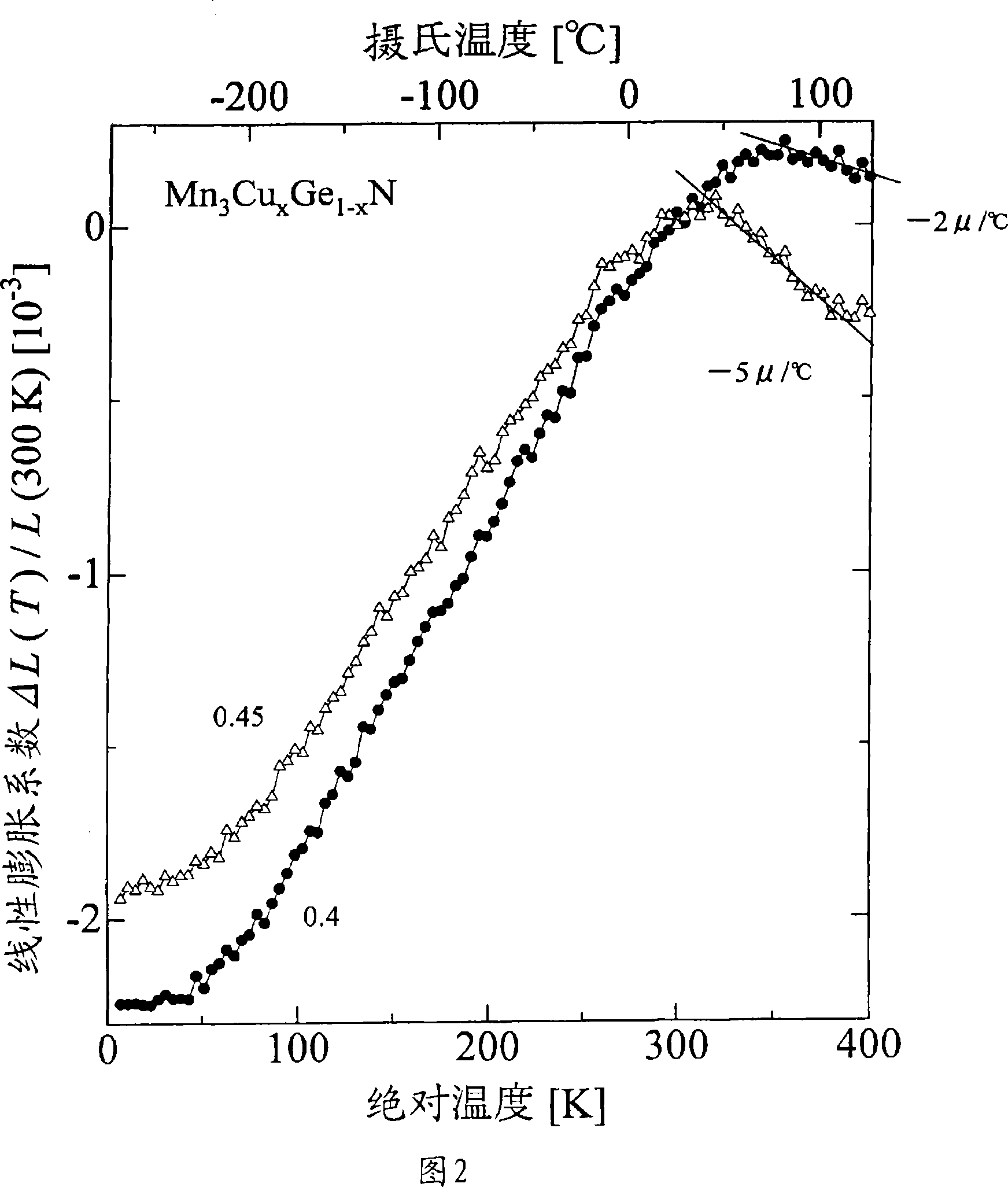

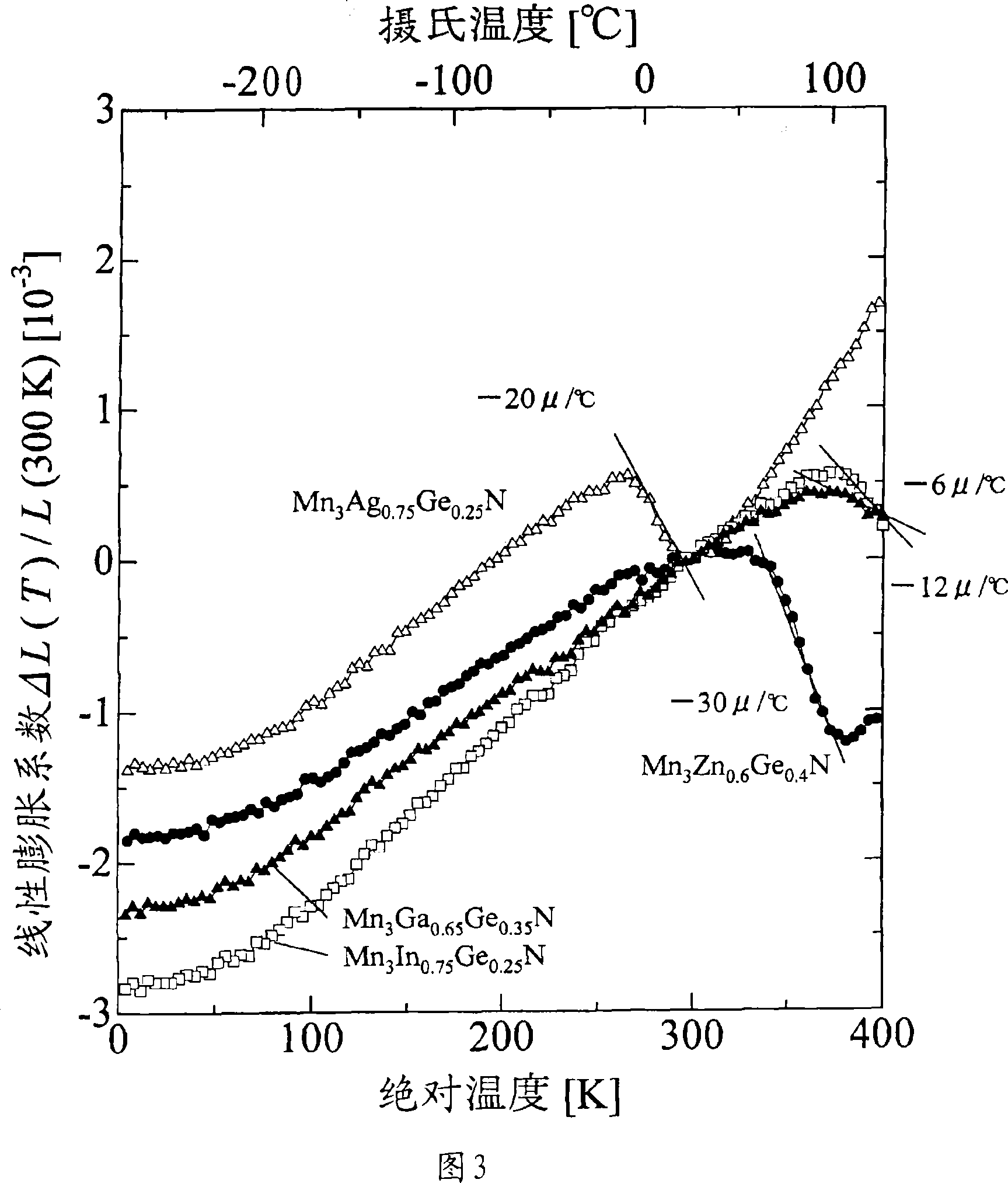

[0160] Moreover, Mn 3 A 1 1-x1 A 2 x1 N is the Mn produced by the above method 3 A 1 N and Mn 3 A 2 The powder of N is mixed and stirred according to the required molar ratio (1-x1): (x1), then compacted into a sheet, sealed in vacuum or heated for 60 hours at 800°C in a nitrogen atmosphere o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com