Exhaust gas system of a motor vehicle with a diesel engine

A diesel engine and exhaust system technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of reduced particle filter unit cost, simplified exhaust system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

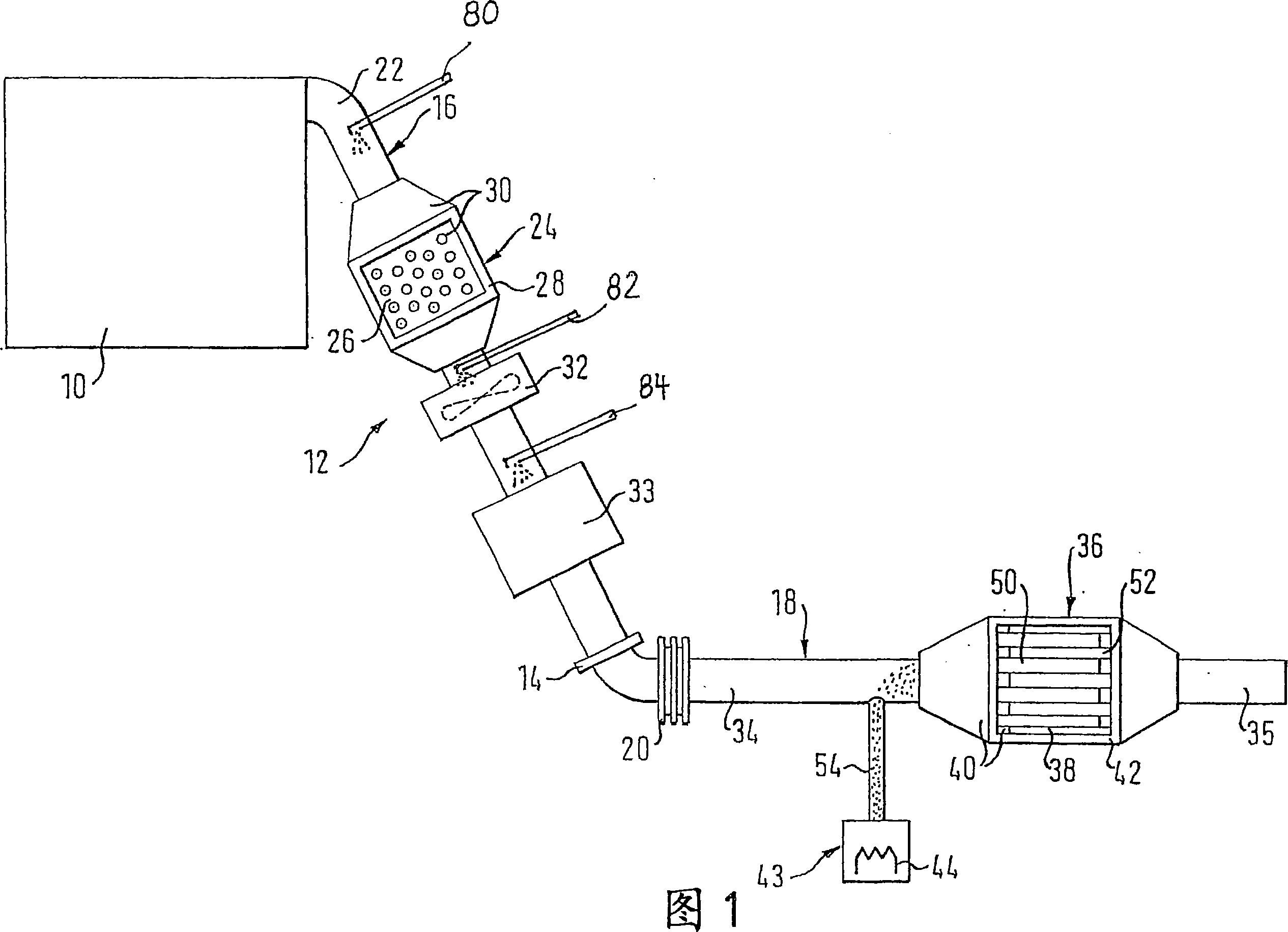

[0027]FIG. 1 shows a diesel engine 10 of a motor vehicle with a downstream exhaust system 12 . The exhaust system 12 has a manifold section 16 which extends as far as the flange 14 and a lower body section 18 adjoining the manifold section 16 downstream, which are connected to each other by vibration isolation means 20 .

[0028] The diesel engine 10 adjoins an exhaust pipe having a first pipe section 22 leading to a particle collector 24 which is arranged in the exhaust system 12 close to the engine.

[0029] The particle collector 24 includes an insert 26 made of ceramic foam or metal and disposed in an outer housing 28 of the particle collector 24 . An oxidation catalytic converter 30 is installed upstream of the insert 26 . However, the oxidation catalytic converter 30 is generally not required because the upstream portion of the insert 26 is properly coated. This means that the oxidation catalytic converter 30 is usually integrated in the insert 26 .

[0030] A turboch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com