Apparatus for cold aseptic filling of a liquid into bottles or similar containers

A filling material and liquid technology, which is applied in the field of equipment for filling liquid filling material into bottles or similar containers with low temperature sterilization, can solve problems such as large structural costs and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

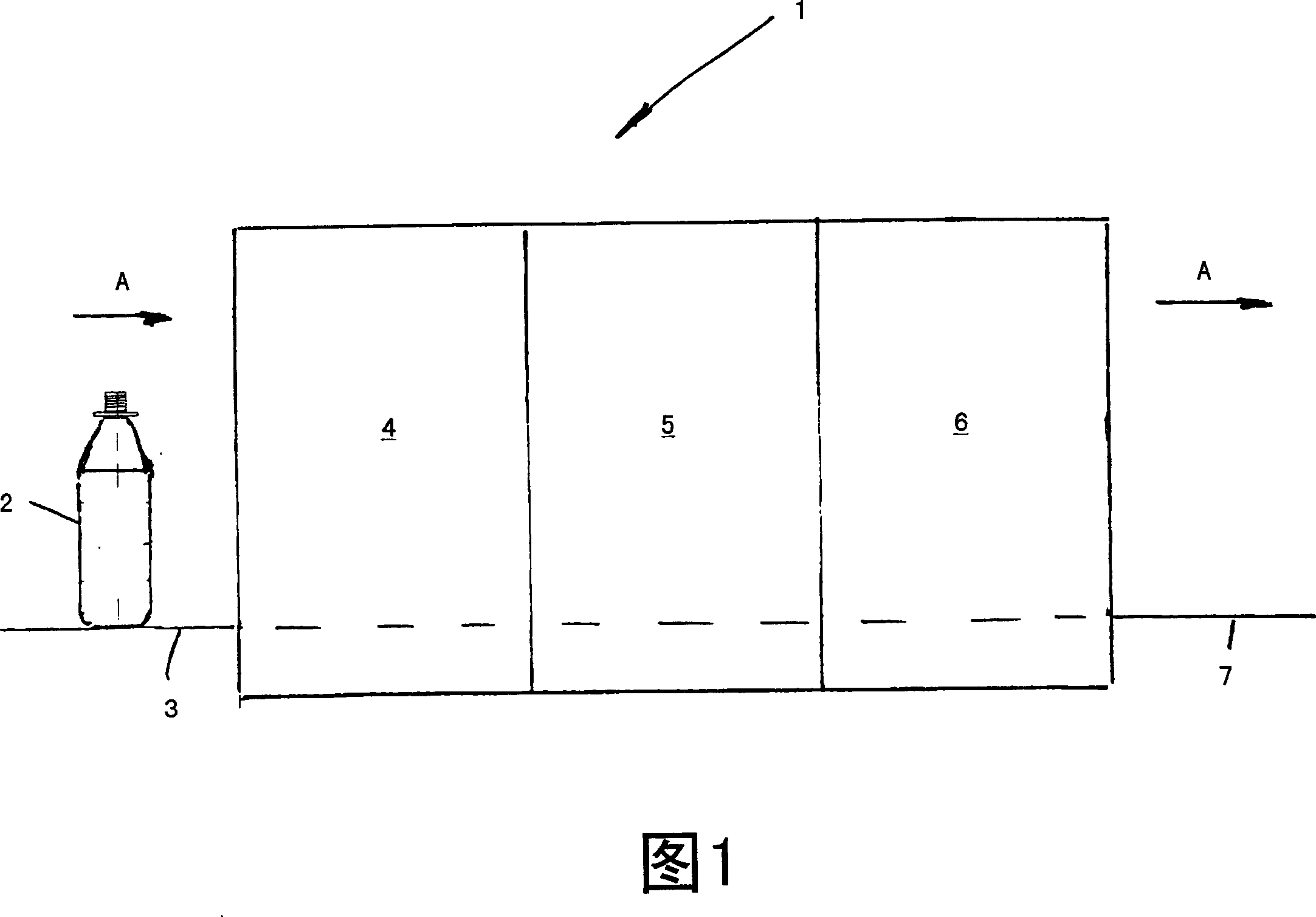

[0038] The overall plant marked with 1 in FIG. 1 is used for the low-temperature aseptic filling of liquid filling products into bottles 2, which are transported in the plant 1 by a conveying device 3 (arrow A), for example in the plant In the first cleaning, in the disinfection device 4 with a suitable treatment medium, mainly by air and hydrogen peroxide (H 2 o 2 ) composed of heated or evaporated gas solvent, then filled with filling in the filling machine 5, and finally sealed in a sealing machine 6, thus, the bottle 2 filled and sealed can be It is fed via the conveyor device 7 to further workstations, for example a labeling machine.

[0039] Inside the device 1 , the bottles move in a sterile, externally sterile-sealed space formed by a corresponding enclosure. However, because the disinfection device 4 is also configured as a machine in the form of a ring structure like other individual machines, such as the filling machine 5 and the sealing machine 6, and possibly al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com