Storied-building board energy-eliminating shock-insulating structure

A floor and energy-dissipating technology, which is applied in the direction of floors, earthquake resistance, and building components, can solve the problems of increased housing cost, large building space, and occupancy, and achieve the effects of enhancing the ability to consume earthquake energy, increasing initial stiffness, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

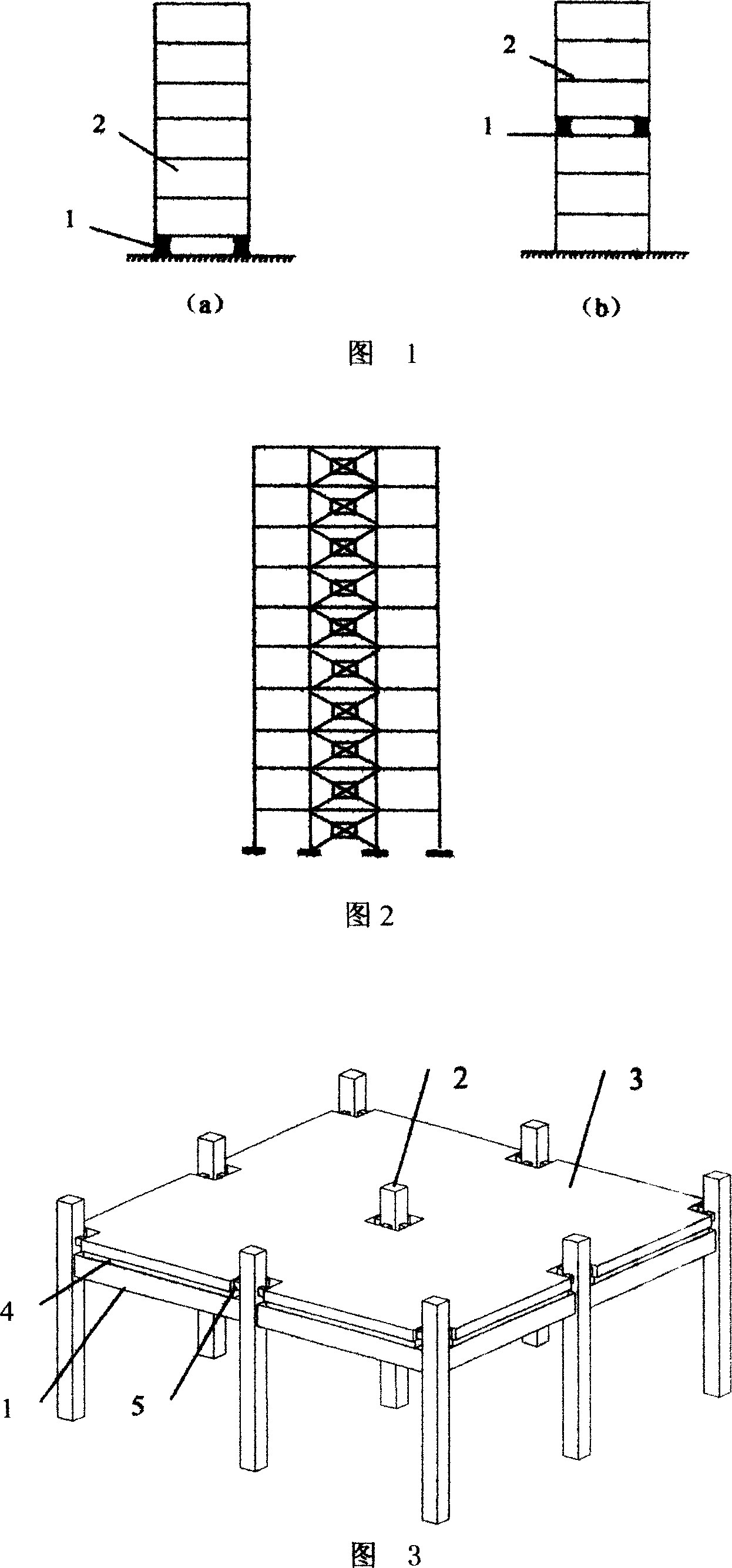

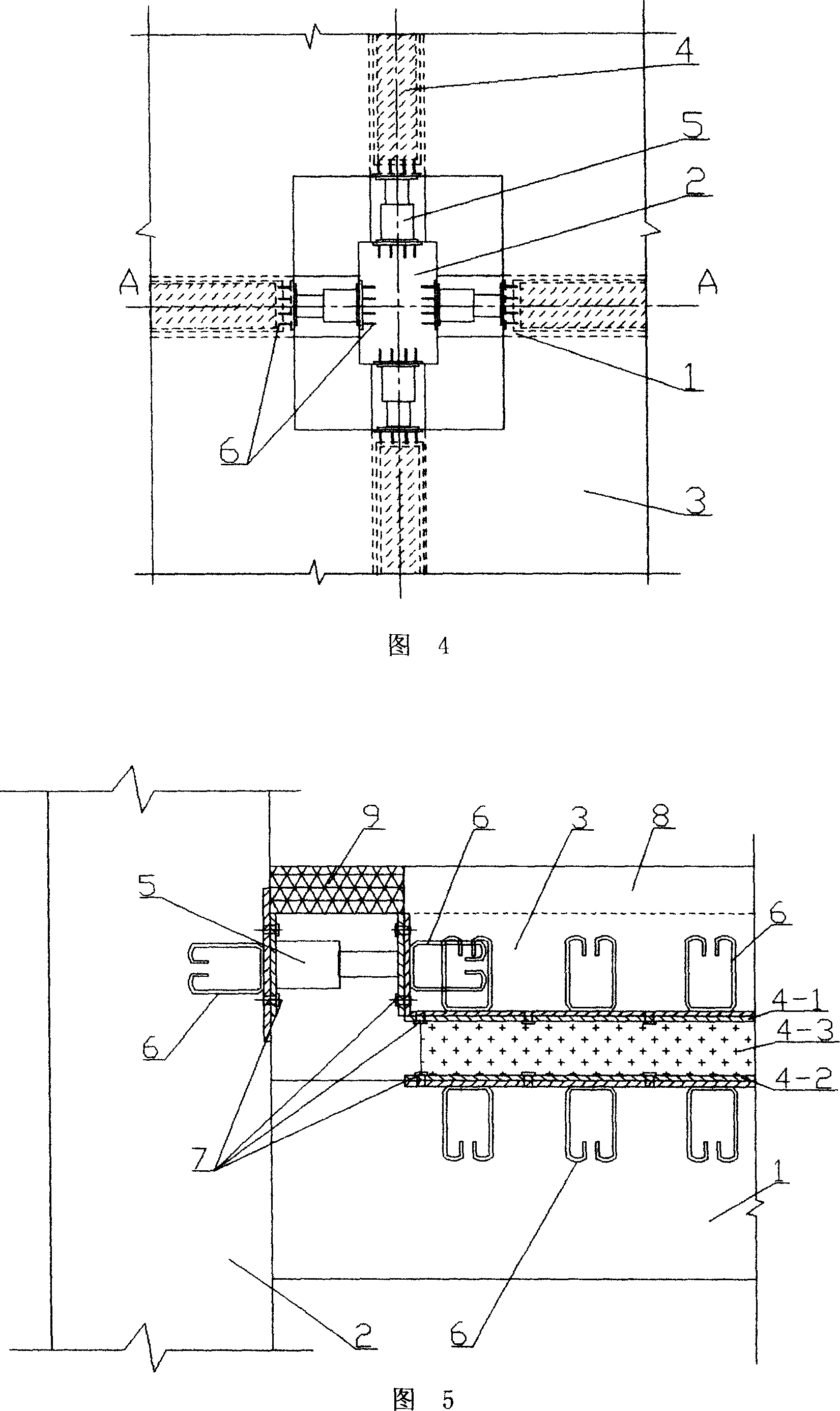

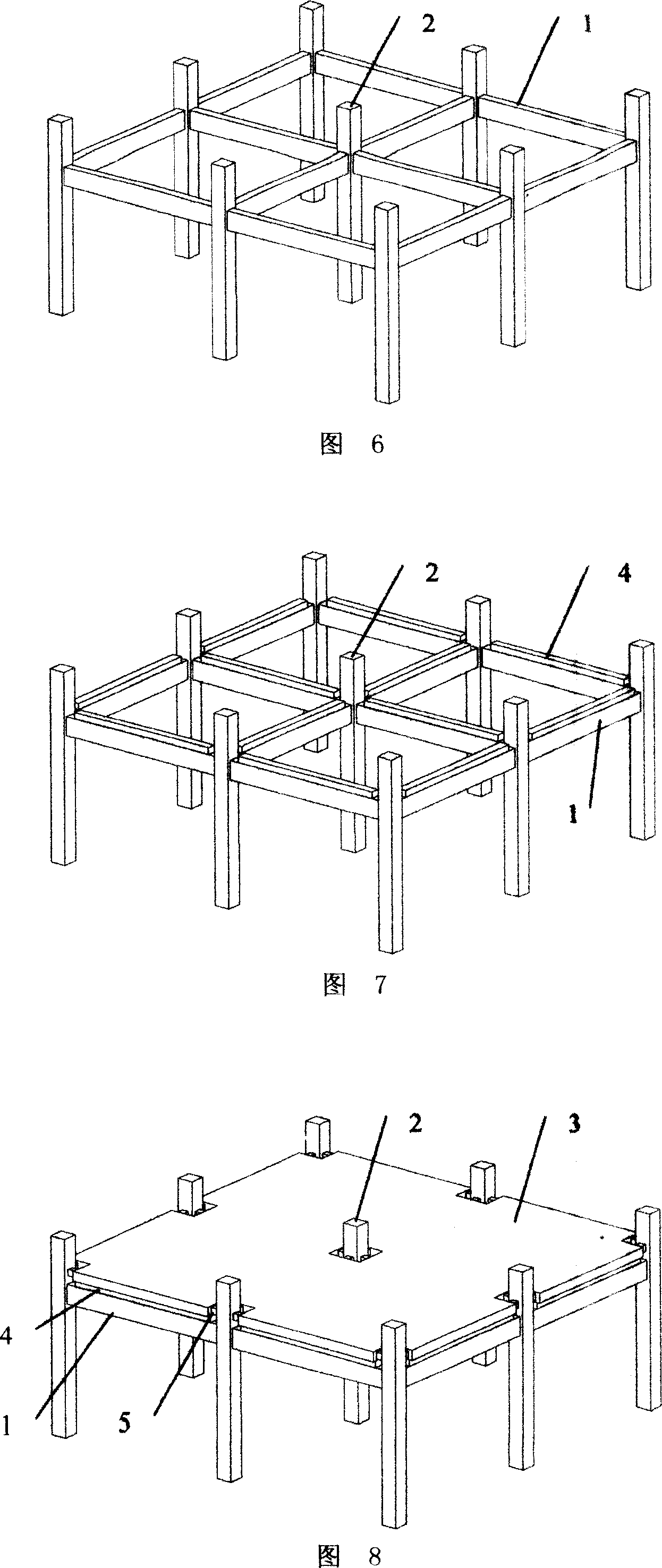

[0047] Referring to Fig. 3, Fig. 4 and Fig. 5, this embodiment is an energy-dissipating and seismic-isolation structure between a floor slab and a reinforced concrete frame beam-column. A damping and shock-isolation layer 4 is provided between the floor 3 and the concrete beam 1 , and an energy dissipation damper 5 is provided between the end face of the floor 3 and the concrete column 2 . Among them, the connecting parts of the concrete beam 1, the floor 3 and the damping and isolation layer 4 are all provided with a connecting piece 6, and the connecting piece 6 uses bolts 7 to connect the concrete beam 1, the floor 3 and the damping and isolating layer 4 into one The connecting part of the concrete column 2 and the end surface of the floor 3 is also provided with a connector 6, and the energy dissipation damper 5 is connected to the connector 6 to connect the concrete column 2 and the floor 3 into one. The damping and isolation layer 4 described in this example is made of l...

example 2

[0055] Referring to Fig. 9, Fig. 10, Fig. 11 and Fig. 12, this embodiment is an energy-dissipating and seismic-isolation structure between a floor slab, a reinforced concrete frame beam column and a shear wall, and the energy-dissipating and seismic-isolation structure is constituted as follows: Concrete beams 1, columns 2, a cylinder surrounded by shear walls 2a, and concrete secondary beams 1' spanning between the two concrete beams 1 form the main structure. Each room is provided with a damping and isolation layer 4, and an energy dissipation damper 5 is provided between the end face of the floor 3 and the concrete column 2 and the shear wall 2a. Among them, the connecting parts of the concrete secondary beam 1', the floor 3 and the damping and isolation layer 4 are provided with connectors 6, and the concrete beam 1', the floor 3 and the damping and isolation layer 4 are connected by the connectors 6 with bolts 7. Linked into one; the concrete column 2, the connecting part...

example 3

[0059] Referring to Fig. 13, in the embodiment described in Example 1 (or Example 2), only a gap 13 may be left between the floor 3 and the vertical load-bearing member (column 2 or shear wall 2a), so that the floor 3 and the vertical Complete isolation from load-bearing members. If this floor is inhabited, described gap 13 also does not need sealing. Other structures of this embodiment can be implemented with reference to Example 1 or Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com