Hot air gun circuit device and its working method

A circuit device and heat gun technology, applied in electric heating devices, electrical components, induction heating, etc., can solve problems such as non-conformity, inaccurate temperature adjustment, interference, etc., and achieve improved control accuracy, simple and convenient operation, and stable and reliable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

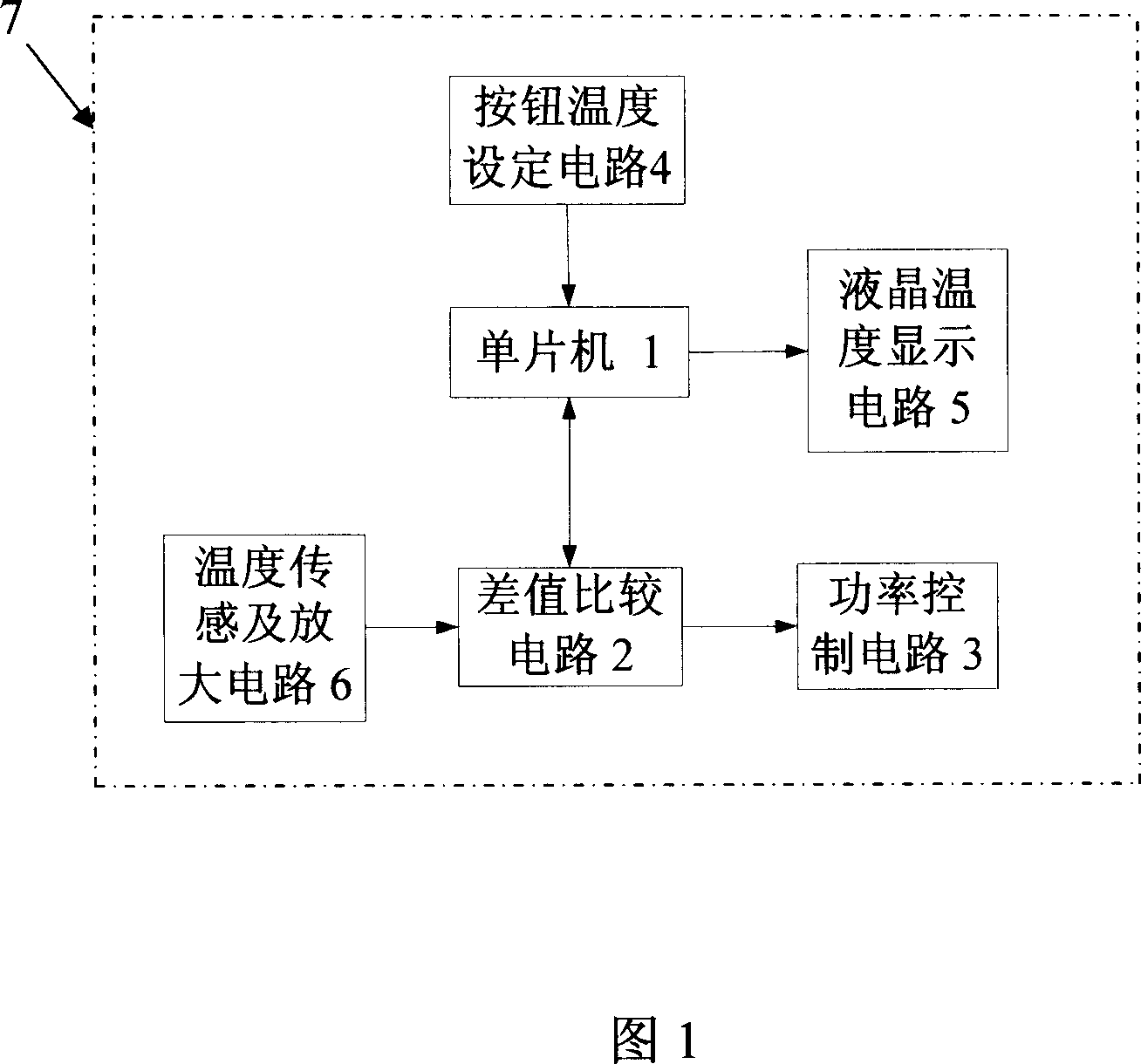

[0020] See Fig. 1, the circuit device of the heat gun of the present embodiment, comprise power supply circuit 8, the temperature control circuit 7 that links to each other with power supply circuit 8 and blower motor, be provided with wind wheel on the blower motor, heating element and temperature control circuit 7 connected.

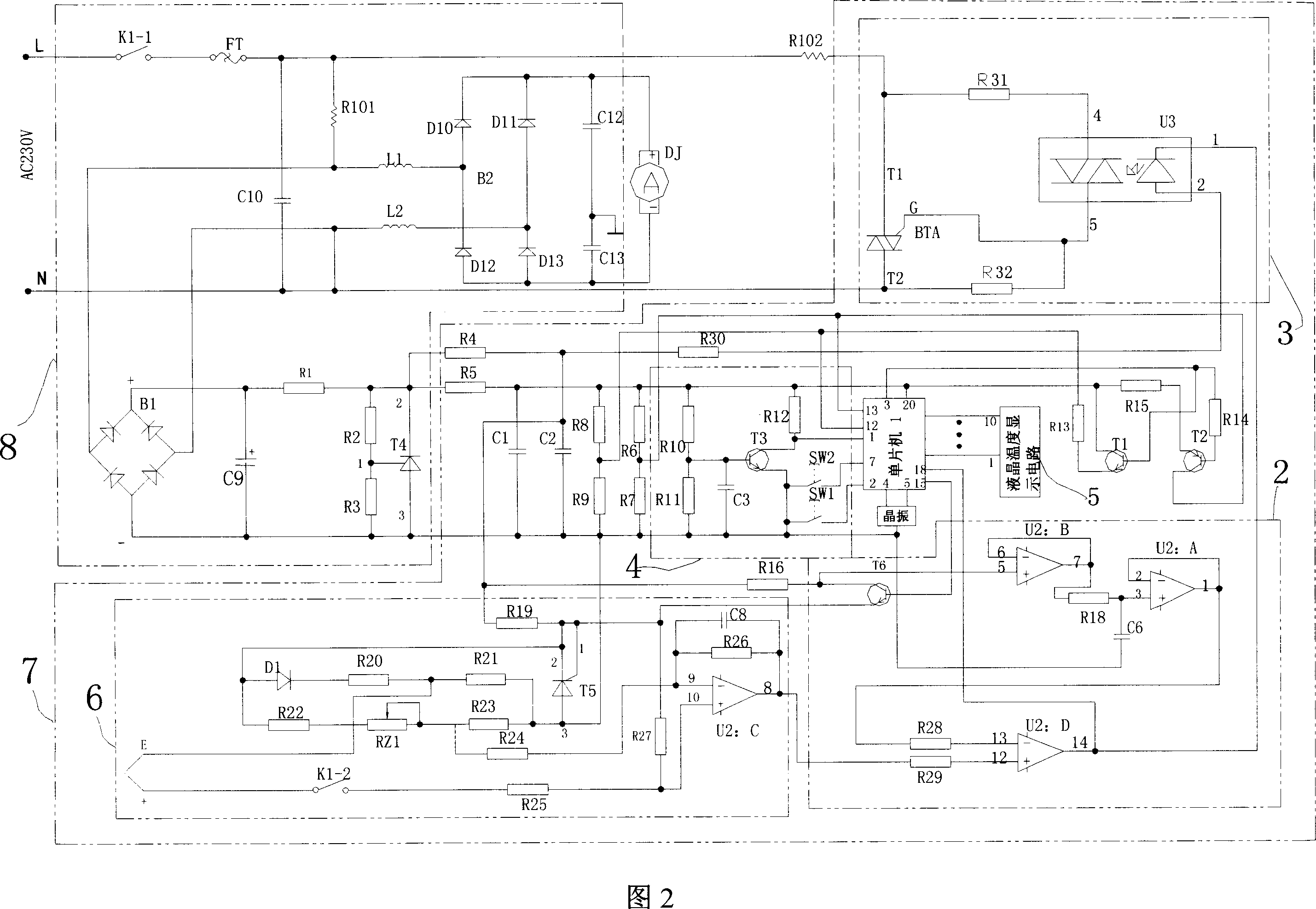

[0021] As shown in FIG. 2 , the power supply circuit 8 includes a switch K1 - 1 , a fuse FT, a drop resistance wire R101 , a filter capacitor C10 , a first rectification circuit and a second rectification circuit. The city alternating current is connected to the AC input terminals of the first rectification circuit and the second rectification circuit through the step-down resistance wire R101; the first rectification circuit is connected to the power supply terminal of the temperature control circuit 7, and the second rectification circuit is connected to the power supply terminal of the blower motor . The first rectification circuit includes a recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com