High-temperature mixed-layer incinerating method and incinerator for fire gate

A high-temperature mixing and incineration device technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problem of large power consumption of the motor, and achieve the effects of increasing combustion efficiency, improving utilization rate, and increasing combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

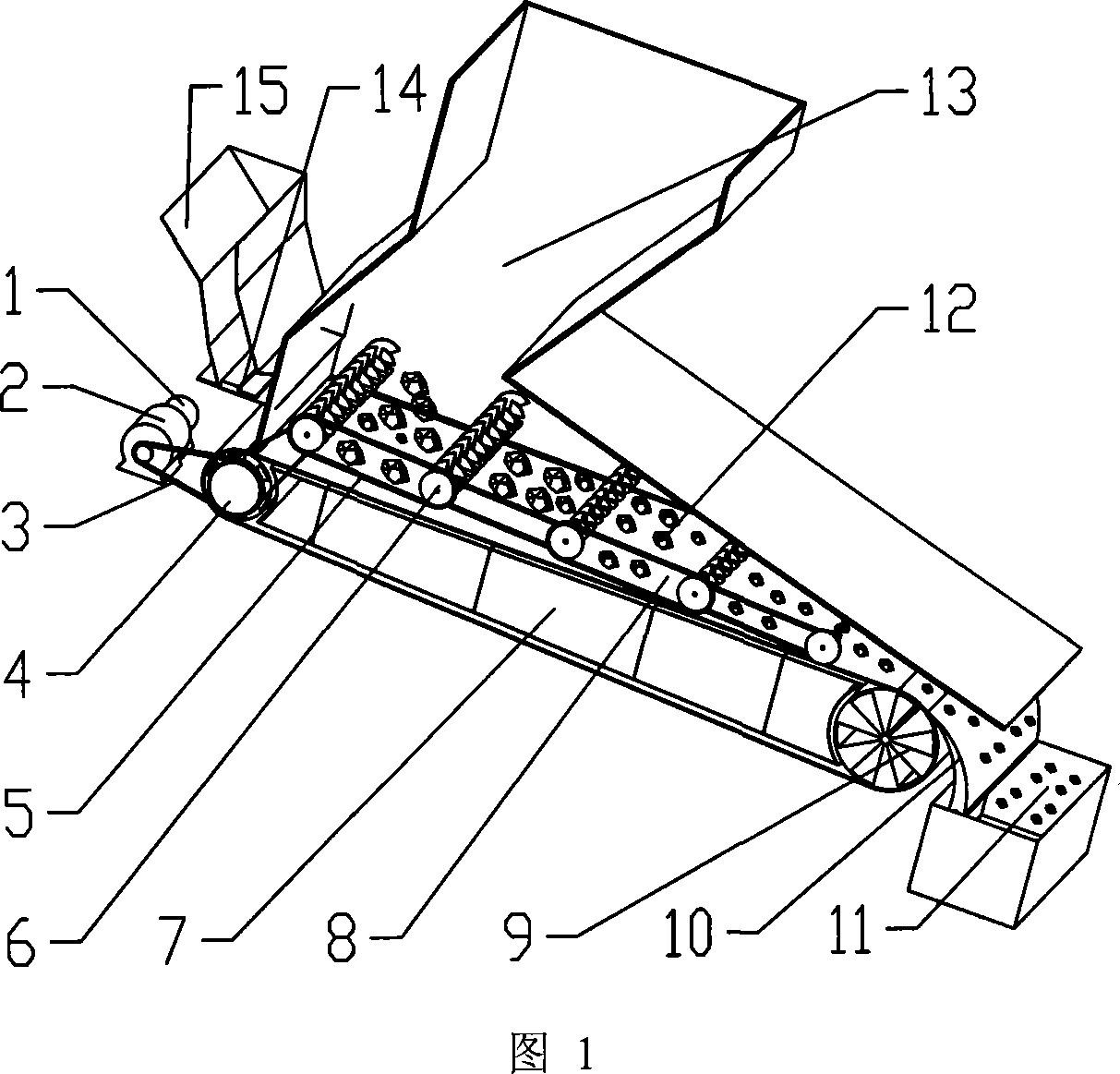

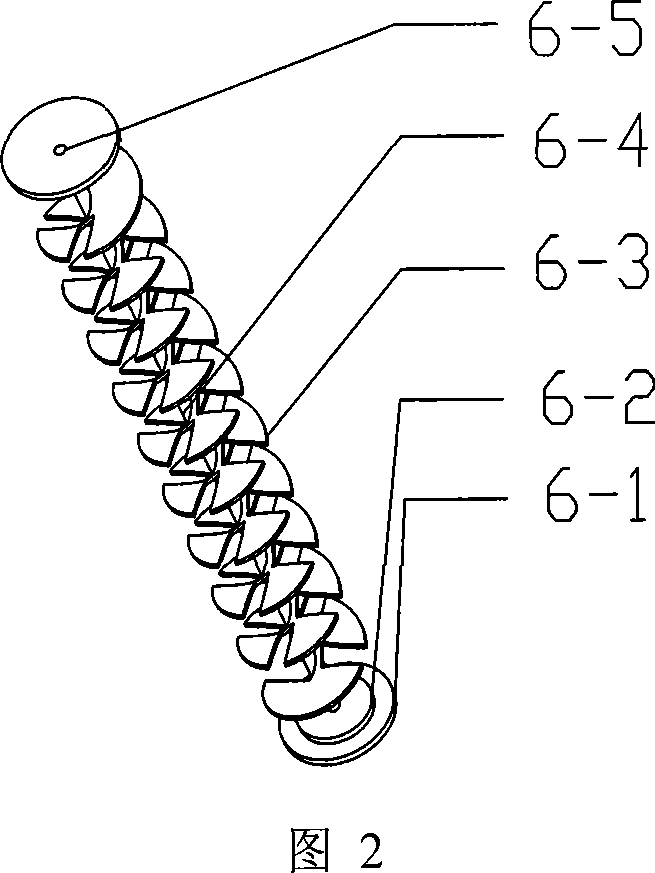

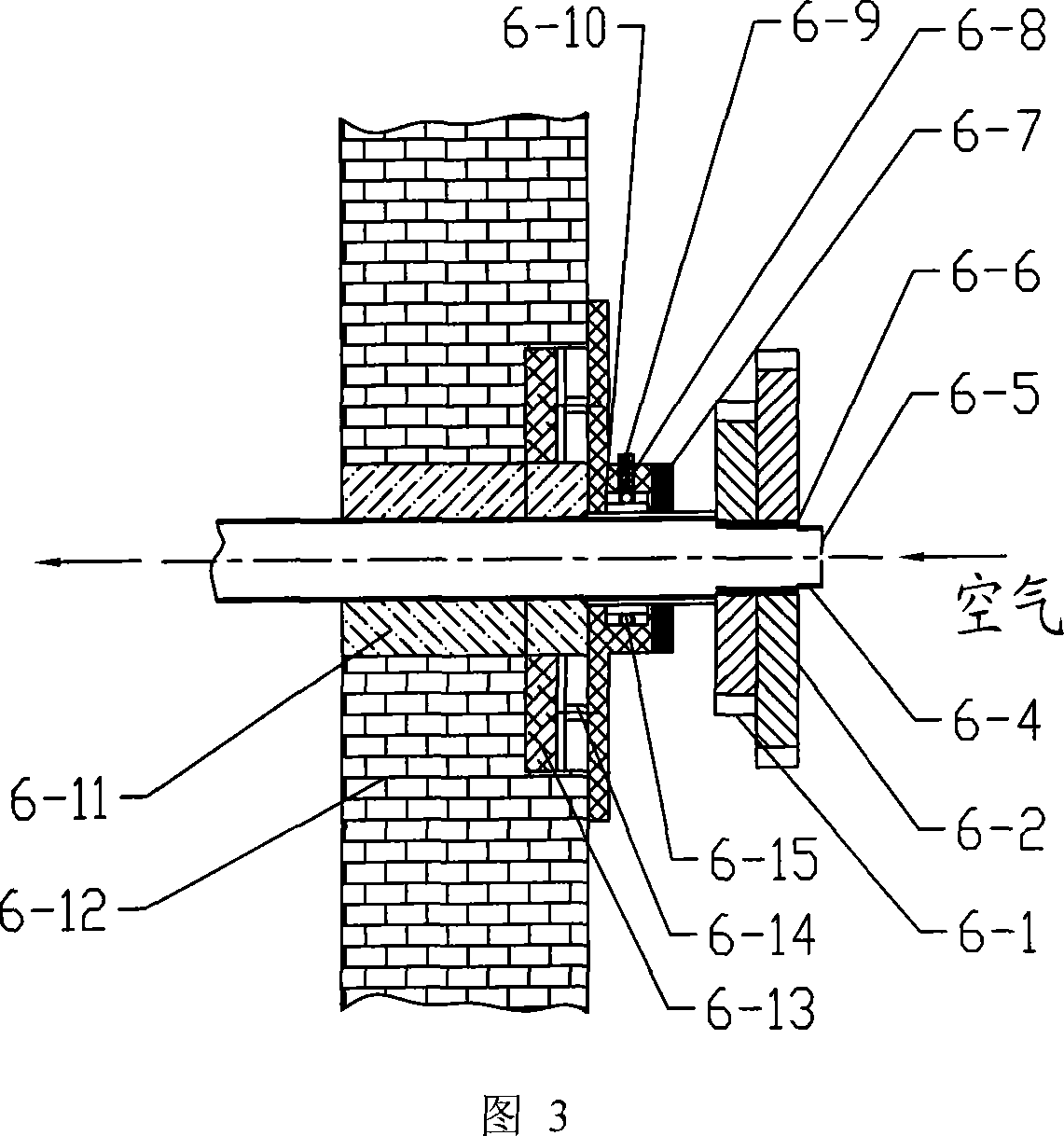

[0027] As shown in Figure 1, the high-temperature mixed layer combustion incineration device for garbage grate includes a motor 1, a transmission 2, a grate chain 3, a drive sprocket 4, a mixer chain 5, a fuel mixer 6, a primary air chamber 7, and a chain grate 8. Driven sprocket 9, ash scraper 10 and ash collector 11.

[0028] The motor 1 is connected to the transmission 2, and the transmission 2 is connected to the drive sprocket 4 through the grate chain 3. The drive sprocket 4 is installed at the starting end of the fire grate 8 in the direction of advancement, and its central axis is connected to the slave wheel installed at the end of the fire grate 8 in the direction of advancement. The central axes of the movable sprockets 9 are parallel, and the upper tangent points of the two sprockets are at the same horizontal position. The speed changer 2 is powered by the motor 1, and the drive sprocket 4 is driven by the speed changer 2 in front of the furnace through the grate ...

Embodiment 2

[0038] The device of this embodiment is the same as that of Embodiment 1, and the difference is that the primary air chamber 7 is a common air chamber, which is not separated by a sealing baffle plate 7-3; there is one fuel mixer 6, and the mixer 6 does not have a driving chain Wheel 6-2, driven sprocket 6-1 is connected with driving sprocket 4.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap