Cutting insert for a tool in particular a milling tool

A technology of cutting elements and inserts, applied in the direction of tools for milling machines, tools for lathes, accessories of tool holders, etc. Damage avoidance, reliable chip formation and chip evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Parts having the same effect in the figures are provided with the same reference numerals.

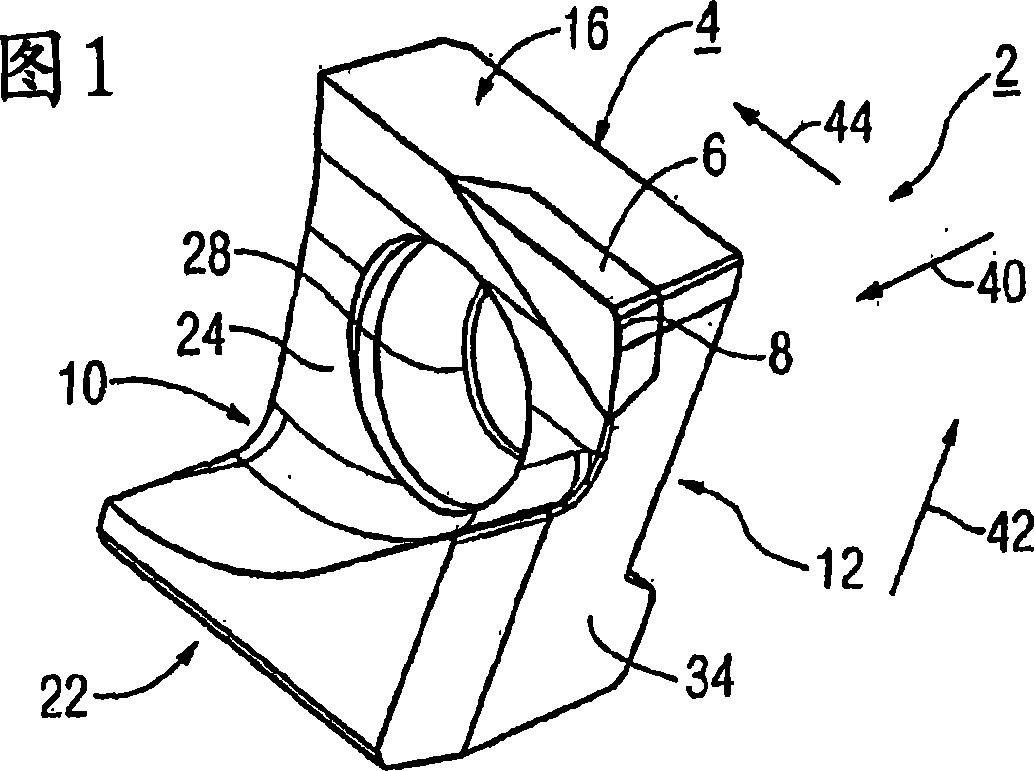

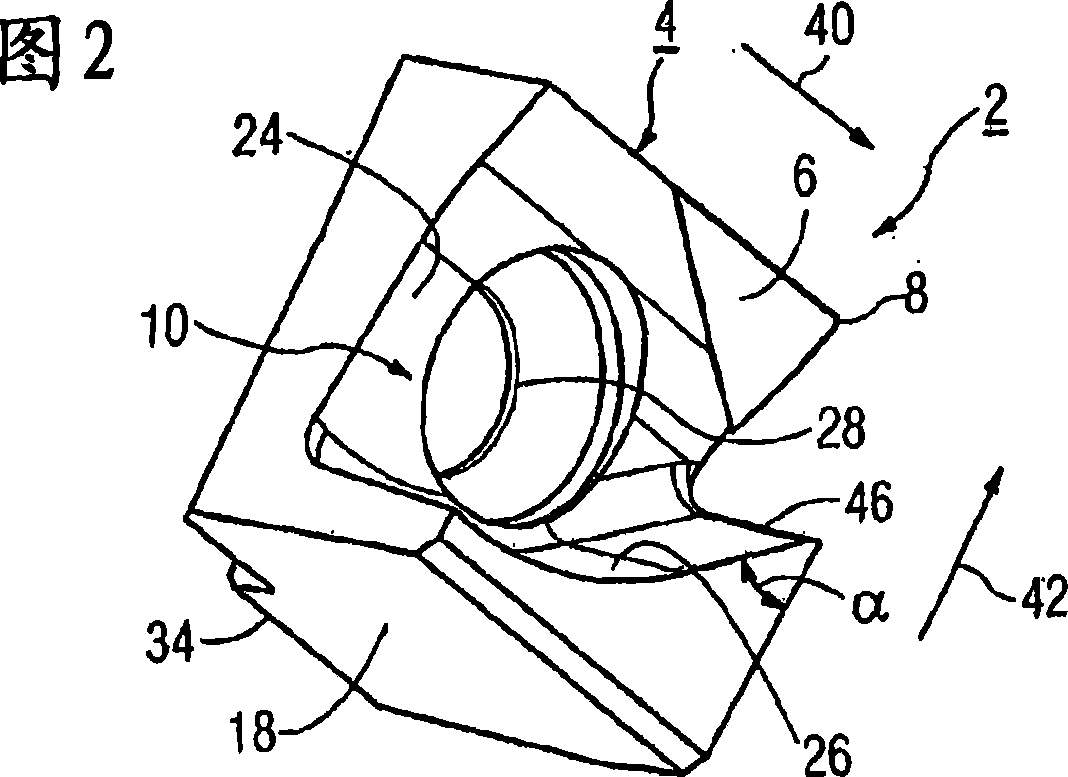

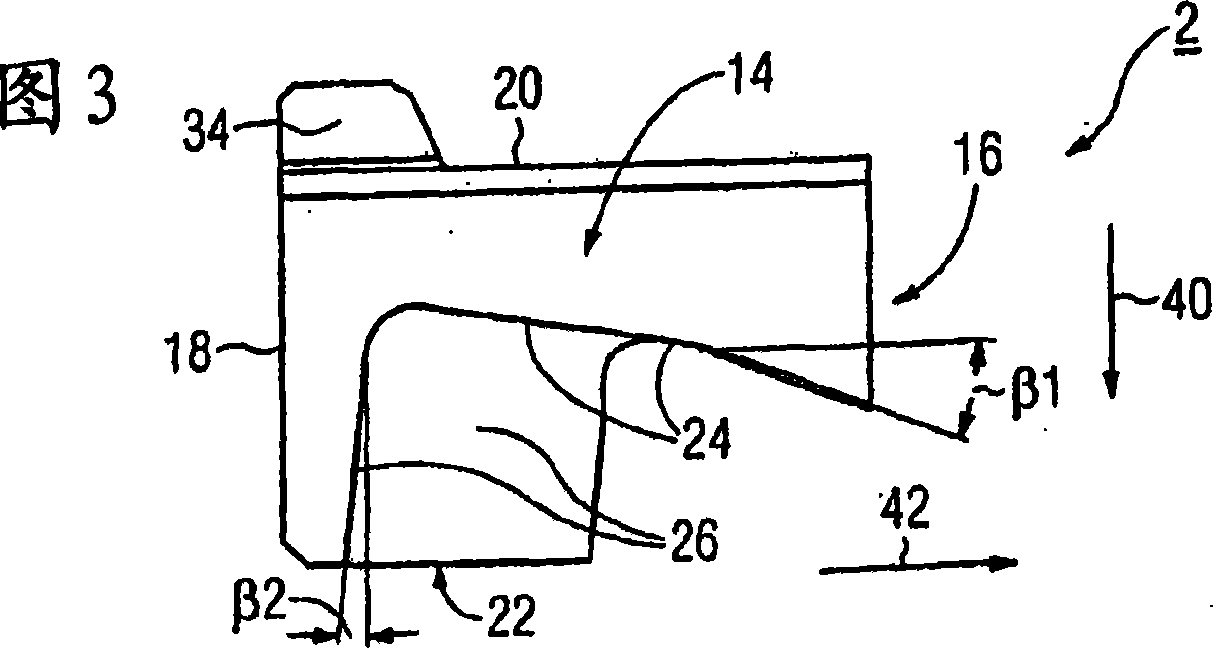

[0030] The cutting inserts described in FIGS. 1 to 5 are formed by a one-piece cutting body 2 which in turn consists of a sintered base body 4 and a cutting element 6 fastened thereto, in particular by brazing. The cutting element 6 is in particular a prism-shaped insert, as can be seen from FIGS. 1 and 2 . The cutting element 6 consists in particular of a polycrystalline diamond material. The base body 4 is produced by a sintering process of metal powder. In particular, complex geometries according to the present exemplary embodiment can be produced economically and with relatively little effort by means of the shaping and production method of the base body 4 .

[0031] The cutting insert 6 has a cutting edge 8 which is formed in particular as a cutting corner. During the machining of metal workpieces, the cutting edge 8 engages with the surface of the workpiece.

[0032]Ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com