Semiconductor assembly comprising a tunnel contact and method for producing said assembly

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as unsupported, large chip area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

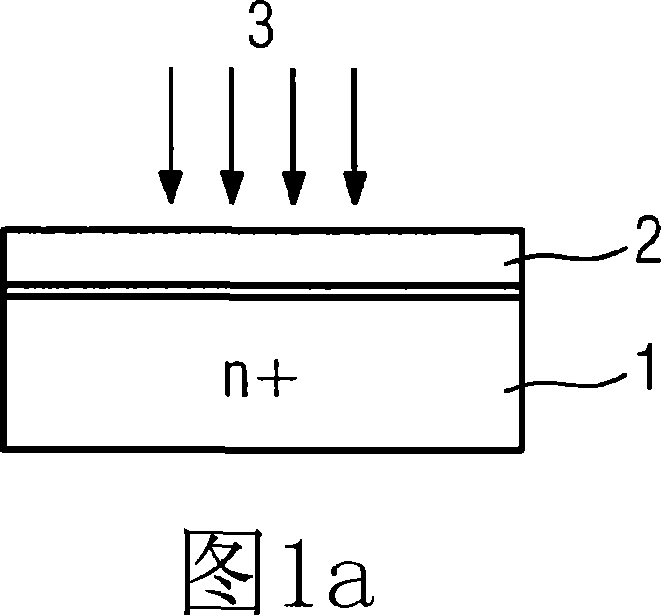

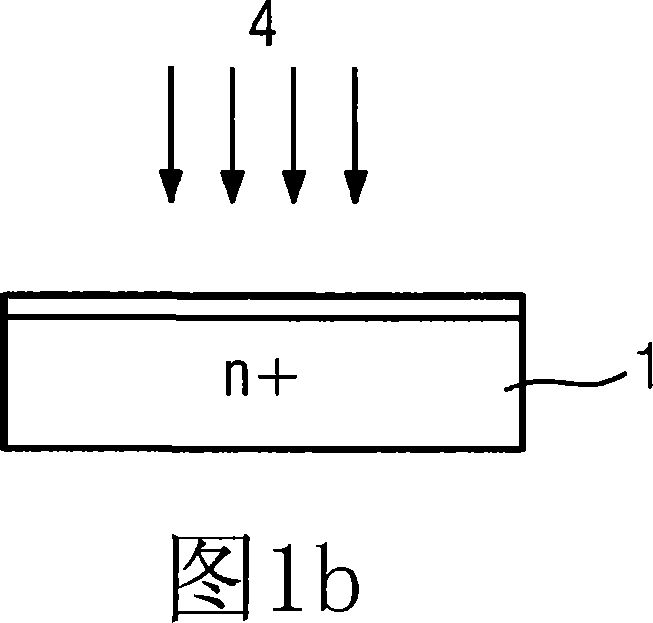

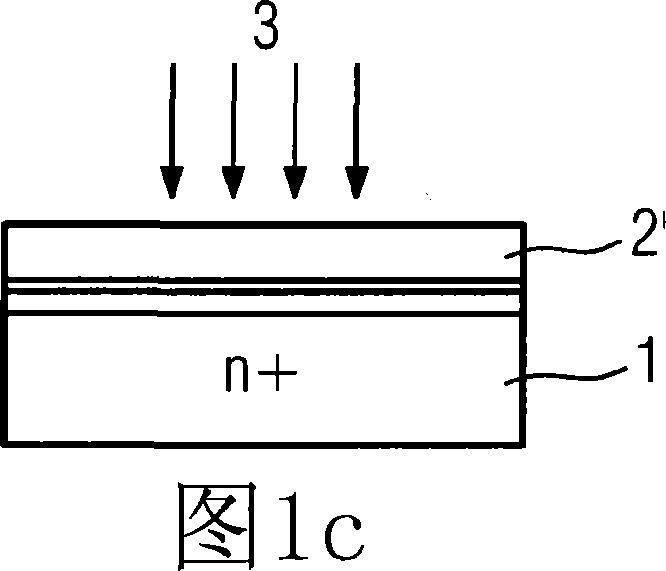

[0017] A semiconductor structure based on silicon carbide (SiC) needs to be equipped with at least one tunnel contact. The ion implantation technology used therein will be explained first with reference to FIGS. 1 a , 1 b and 2 . The use of the semiconductor structure in a SiC layer structure with corresponding electrodes, by means of which an IGBT-type component can be realized, is then explained with reference to FIGS. 3 and 4 .

[0018] FIG. 1 shows an N-type substrate 1 with a coating 2 . As shown in Figure 1a, using an energy of 25kV and a very high dose (>10 13 / cm 2 ) shallow implantation of aluminum ions3. In addition to aluminum ions, implantation of boron (B) ions may also be considered if necessary.

[0019] In an alternative as shown in Fig. 1b, a shallow implant of 25 kV is first used in substrate 1 with a very high dose (>10 13 / cm 2 ) of nitrogen ions 4, thereby forming a coating 2'. Subsequently, as shown in Figure 1a, the injection dose was very high (>...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com