Method of producing electrode for titanium alloy vacuum consumable smelting directly added with high melting metal

A vacuum self-consumption smelting and high-melting-point metal technology, which is applied in the field of high-quality ingots without segregation, can solve the problems of high energy consumption, large investment in equipment, increased production processes, and material loss in production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

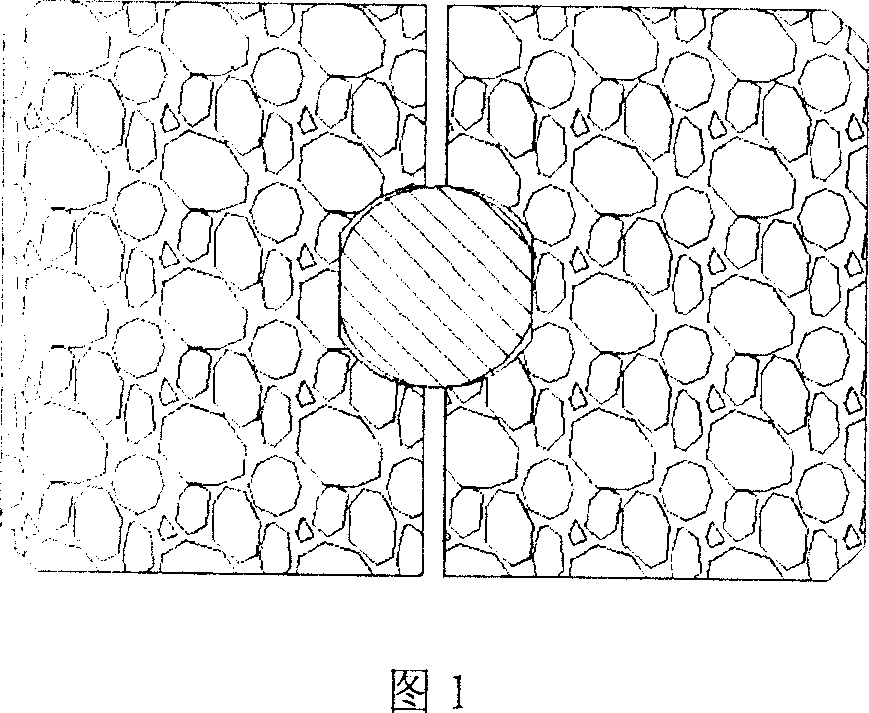

[0012] Grade 1 sponge titanium, aluminum beans and Φ35×2800mm Nb smooth round rods are used as raw materials, and the electrode is prepared according to the nominal composition Ti-45Al-10Nb (wt%). The electrode block is made of sponge titanium and aluminum beans. After the layers are arranged and pressed, the size of the electrode block is 300×130×90mm, and a semicircular electrode block with a surface groove of Φ35mm is welded into a single row of 8 sections with a length of 2800mm, and then Nb round rods are embedded in the groove. The electrode block is multi-point welded, and then the electrode block is covered and welded to form the whole electrode (see attached picture 1). The whole electrode mandrel and the electrode block are combined compactly, with a unit weight of 100Kg, which meets the requirements of a Φ280mm water-cooled copper ingot. The size requirements of the crucible for the electrode, the subsequent selection of a suitable vacuum consumable arc melting proce...

Embodiment 2

[0014] Grade 1 sponge titanium, industrial grade sponge zirconium and Φ35×2800mm Nb light round rod are used as raw materials, and the electrode is made according to the nominal composition Ti-13Nb-13Zr (wt%). The electrode block is made of sponge titanium and sponge zirconium. Arranged in layers and then pressed, the size of the electrode block is 300×130×65mm, and the surface groove is a semicircle of Φ35mm. The electrode blocks are welded into a single row of 8 sections with a length of 2800mm, and then Nb round rods are embedded in the groove. The head section and the electrode block are welded at multiple points, and then the electrode block is covered respectively and welded to form the whole electrode (see attached figure 1). The whole electrode mandrel and the electrode block are combined compactly, with a single weight of 160Kg, which meets the requirements of an ingot The Φ220mm water-cooled copper crucible has the size requirements for the electrode, and then selects...

Embodiment 3

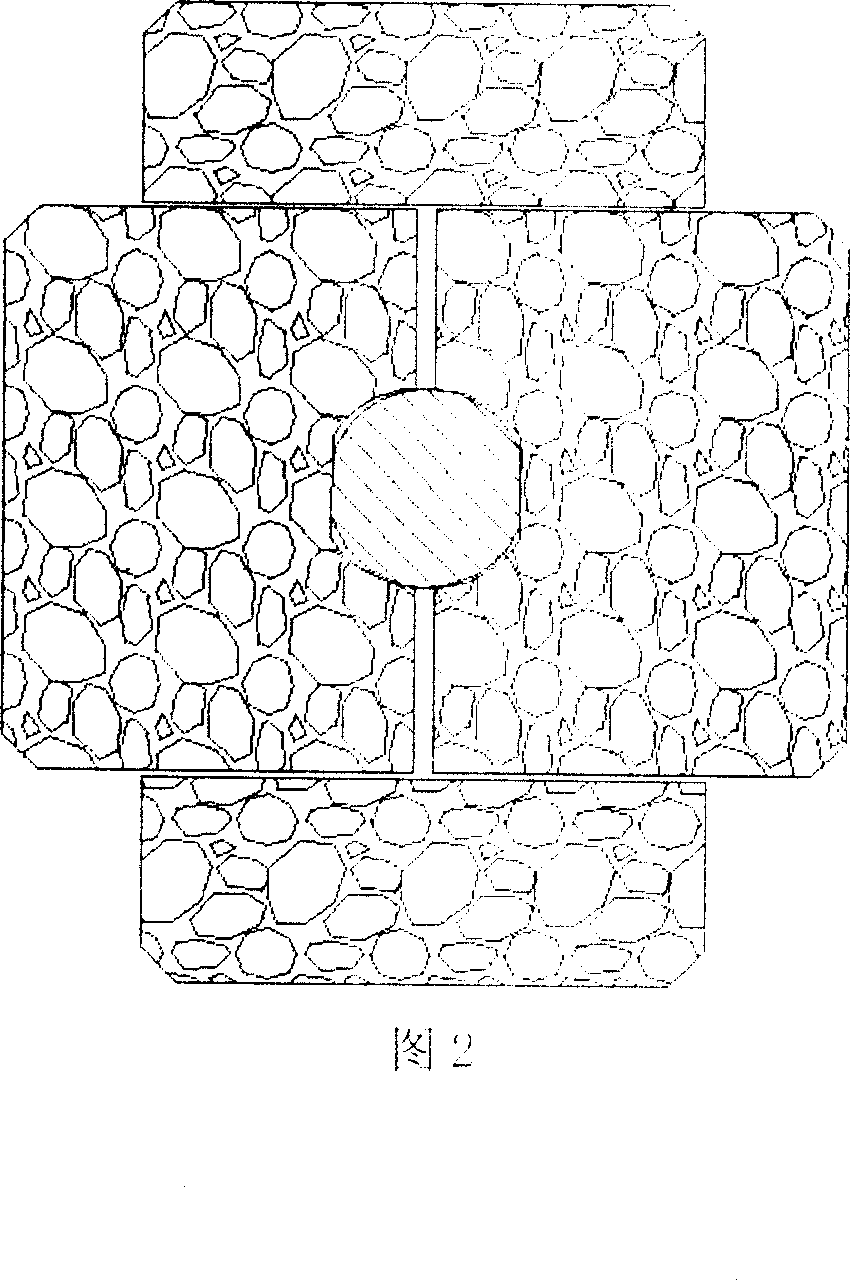

[0016] Grade 1 sponge titanium, aluminum beans and Φ35×2800mm Nb smooth round rods are used as raw materials, and the electrodes are made according to the nominal composition Ti-6Al-7Nb (wt%). The electrode block is made of sponge titanium and aluminum beans. Pressed after layer arrangement, the size of the large electrode block is 300×130×80mm, one surface groove is a semicircle of Φ13mm, the other surface groove is a semicircle of Φ35mm, the size of the small electrode block is 300×130×40mm, and the electrode blocks are welded into a single A row of 8 sections with a length of 2800mm, and then embedded Nb round rods in the groove, and multi-point welding between the two end sections and the electrode block, and then correspondingly covering the electrode block and welding to form a whole electrode (see Figure 2). The combination of electrode mandrel and electrode block is compact, with a unit weight of 135Kg, which meets the size requirements of the Φ280mm water-cooled copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com