Concave-convex rotary engine

A rotary engine and concave cam technology, applied in the field of fuel engines, can solve the problems of large space and large shape of fuel engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

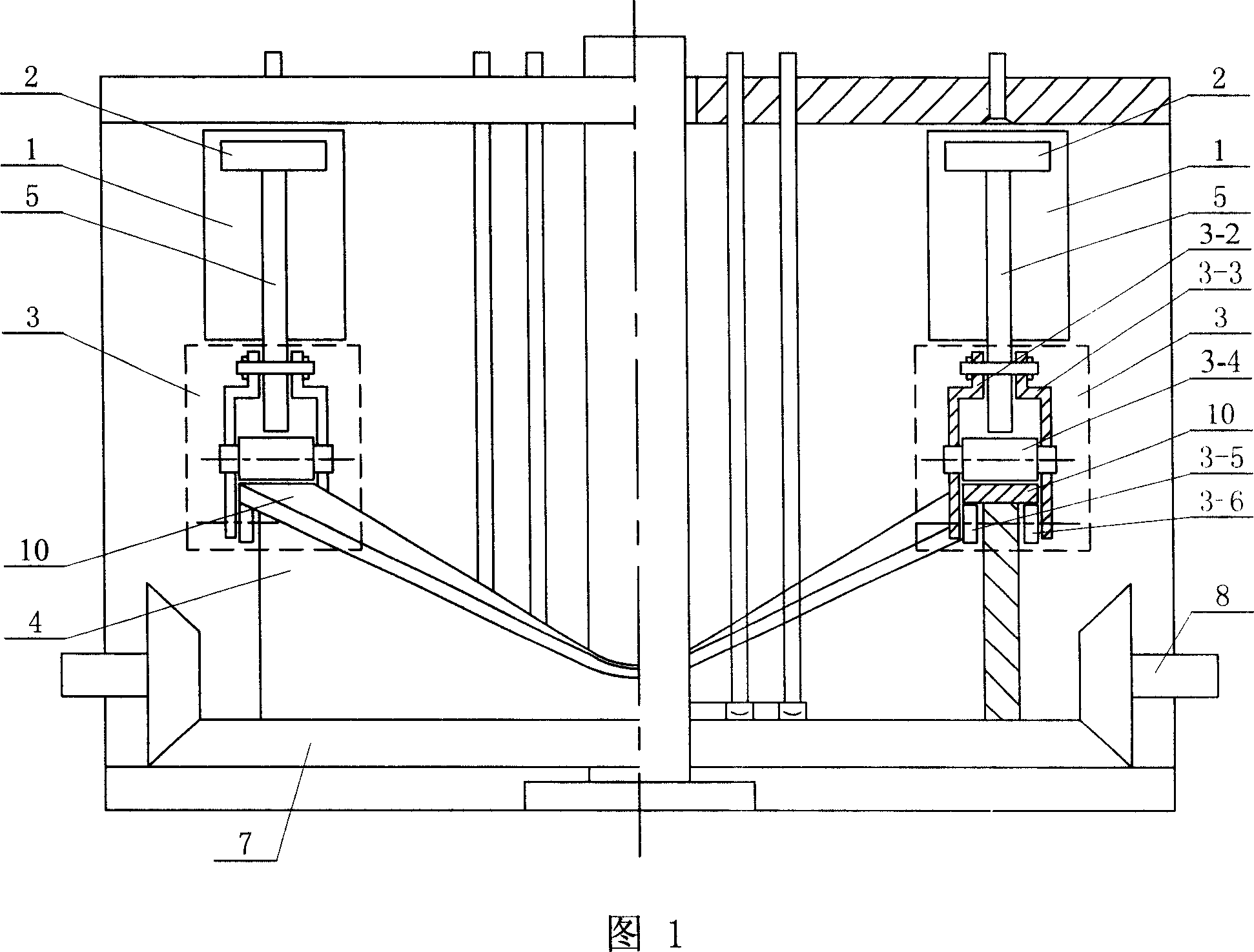

[0005] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 . This embodiment is composed of two cylinders 1, two pistons 2, two dowel rods 5, two sets of connecting mechanisms 3, guide strips 10 and concave-convex wheel 4, the upper surface of the concave-convex wheel 4 has a height difference along its Guide bar 10 is fixed on the peripheral edge, cylinder 1 is arranged on the top of guide bar 10, two cylinders 1 are evenly distributed along the circumferential direction of guide bar 10, the upper end of dowel bar 5 is fixed on piston 2, and the dowel bar The lower end of 5 is connected with the guide bar 10 through the connecting mechanism 3 so as to realize the sliding of the lower end of the dowel 5 along the guide bar 10 . Connecting mechanism 3 is made up of left connecting splint 3-2, right connecting splint 3-3, upper wheel 3-4, left lower wheel 3-5 and right lower wheel 3-6, and left lower wheel 3-5 is arranged o...

specific Embodiment approach 2

[0006] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . The difference between this embodiment and Embodiment 1 is that it also includes a large bevel gear 7 and a small bevel gear 8, the large bevel gear 7 is fixed on the lower end surface of the concave-convex wheel 4 and is coaxial with it, the small bevel gear 8 and the large bevel gear The bevel gears 7 are meshed. In this embodiment, the rotary motion of the concave cam wheel 4 is output through the small bevel gear 8, and the large bevel gear 7 is used as the driving wheel to drive the small bevel gear 8, which improves the output speed. Therefore, under the same fuel consumption, the speed ratio The existing crankshaft internal combustion engine is more than doubled, reflecting good power and fuel economy.

specific Embodiment approach 3

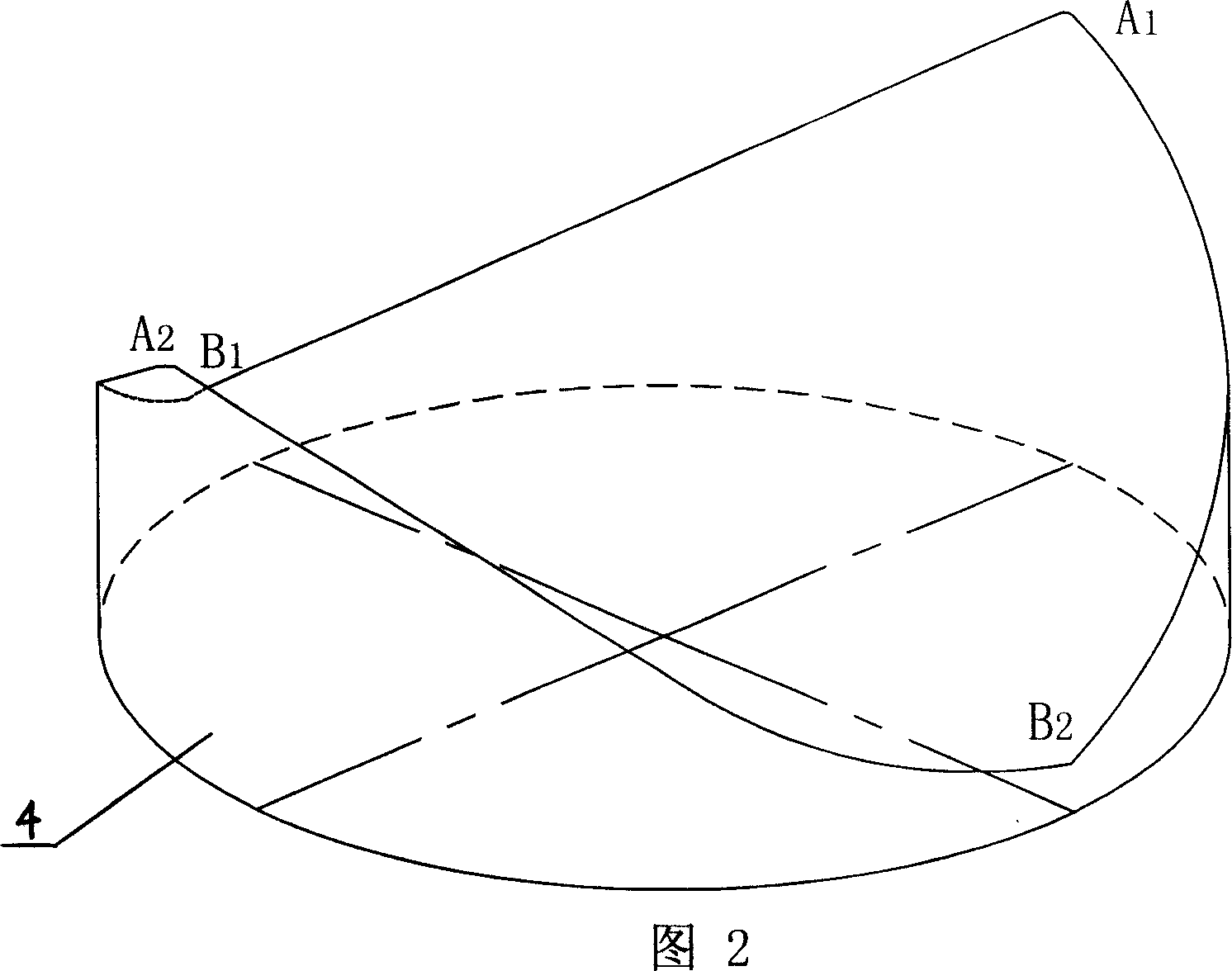

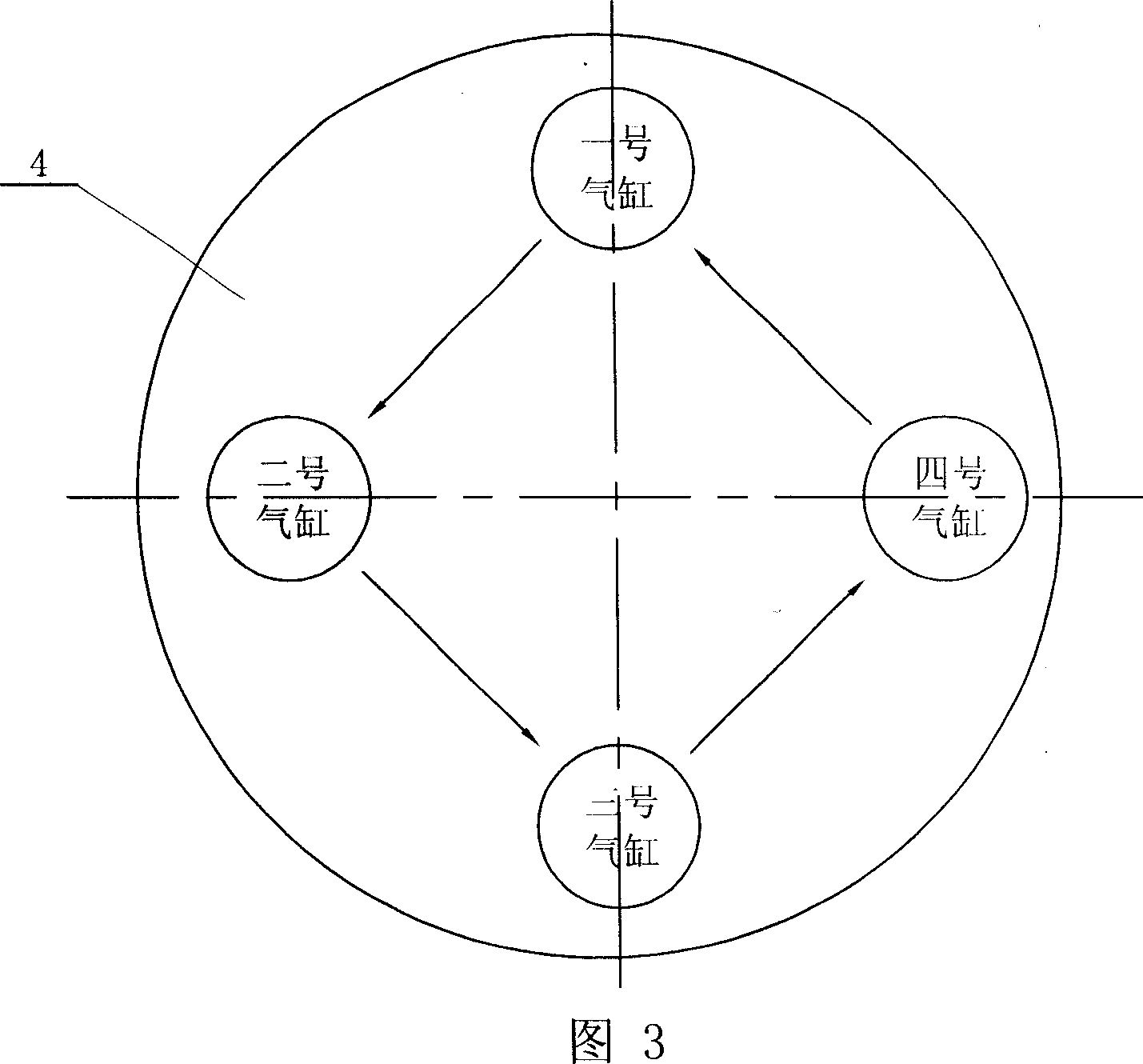

[0007] Specific Embodiment Three: The present embodiment will be specifically described below with reference to FIG. 2 and FIG. 3 . The difference between this embodiment and Embodiment 1 is that the upper end surface of the concave-convex wheel 4 is provided with a first raised high point A1, a first depressed low point B1, a second raised high point A2 and a second depressed low point B2 , the first convex high point A1, the first concave low point B1, the second convex high point A2 and the second concave low point B2 are uniformly arranged on the circumferential edge of the concave cam wheel 4 in sequence along the circumferential direction of the concave cam wheel 4, Cylinder 1, piston 2, dowel 5 and connecting mechanism 3 are respectively provided with four groups. Because there are two high points and two low points, this embodiment can implement a system cycle of continuous operation with continuous ignition. The ignition sequence is cycled in the working order of No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com