Wireless receiving microelectronic mechanical microwave power sensor and manufacturing method therefor

A micro-electronic machinery and microwave power technology, applied in the direction of electromagnetic field characteristics, etc., can solve the problem of not being able to directly receive microwave power, and achieve the effect of broadening the microwave measurement frequency band, reducing return loss, and achieving impedance matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

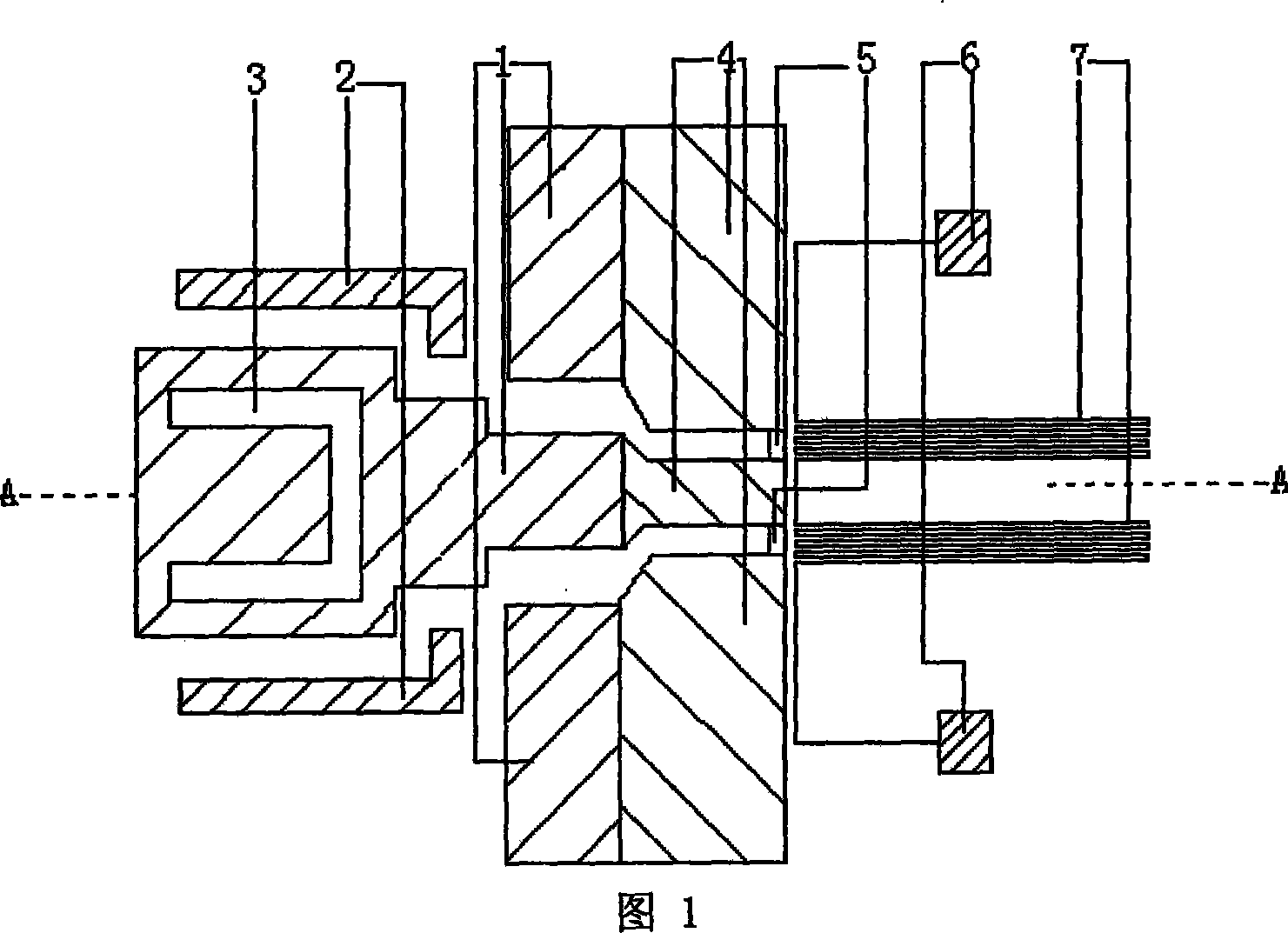

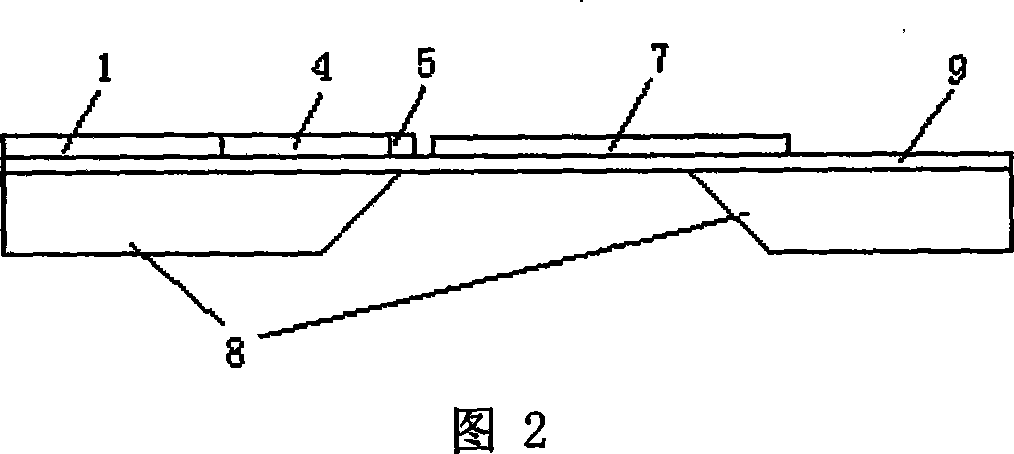

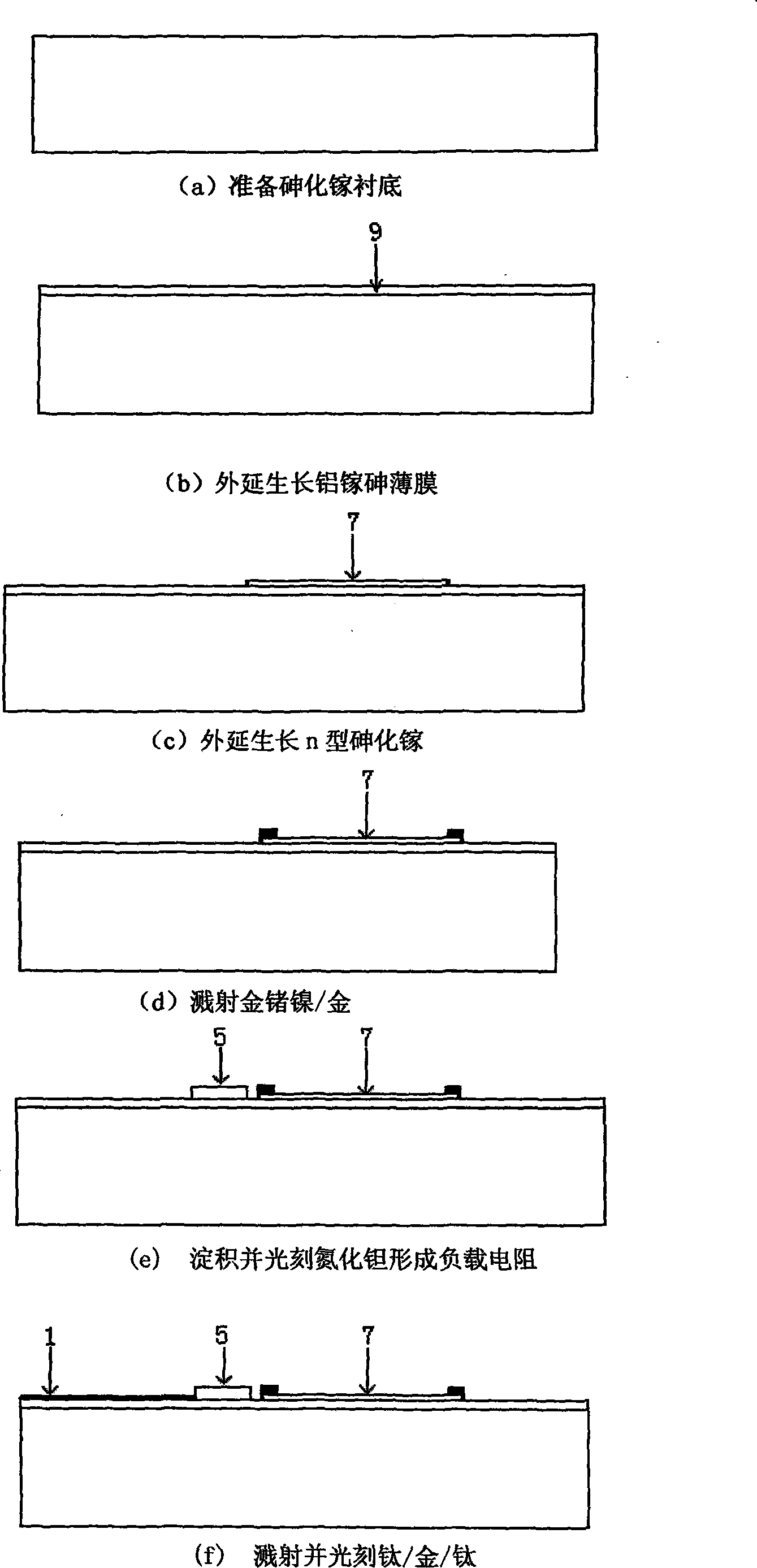

[0032] The sensor uses gallium arsenide as the substrate 8, on the gallium arsenide substrate 8 there is a layer of AlGaAs thin film 9, on the AlGaAs thin film 9 there is a layer of coplanar waveguide antenna 1, and a section of the antenna is etched away The U-shaped slot 3 has a parasitic element patch 2 on both sides of the antenna, the end of the coplanar waveguide antenna 1 is connected to the coplanar waveguide transmission line 4, and there are two parallel load resistors at the end of the coplanar waveguide transmission line 4, and the load resistor 5 The outer side of the thermopile is correspondingly provided with a thermopile 7, and the two ends of the thermopile 7 are connected to the two pressure welding blocks 6 through wires. The present invention receives the microwave signal from the outside through the special structure coplanar waveguide antenna at the front end, and then transmits the microwave signal to the terminal th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com