Automation hot- press machine

A technology of hot press and hot press, applied in the field of hot press, can solve problems such as inapplicability, instability, and inability to use one machine for multiple purposes, and achieve the effects of simplifying operations, reducing costs, and improving equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

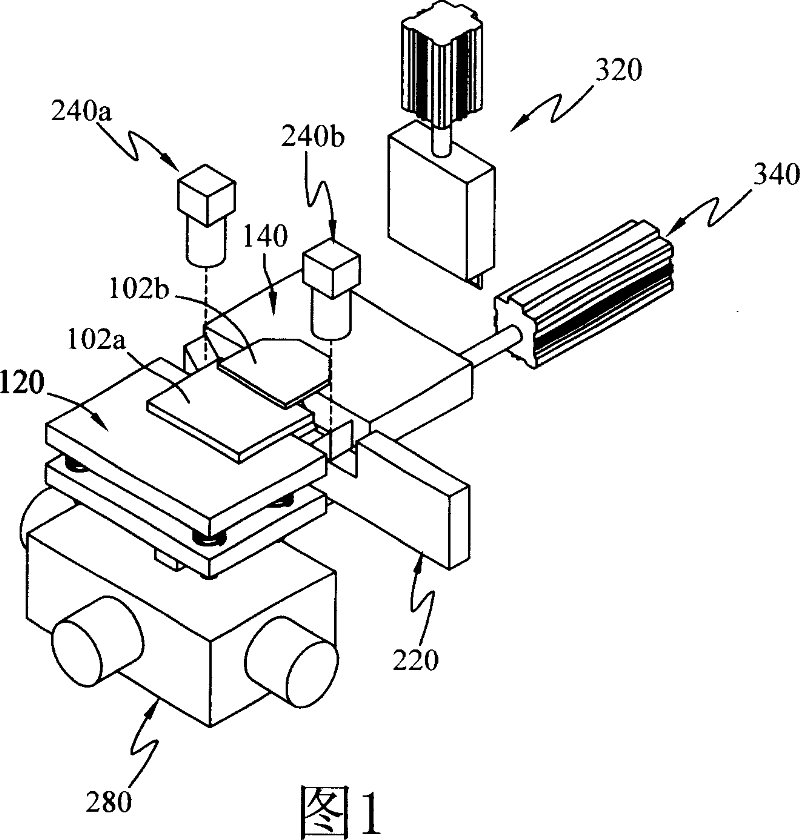

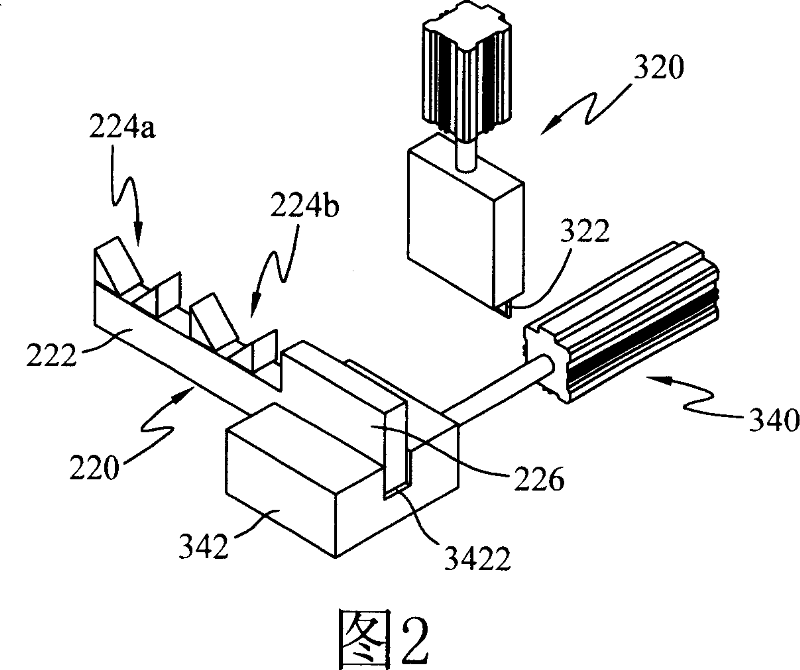

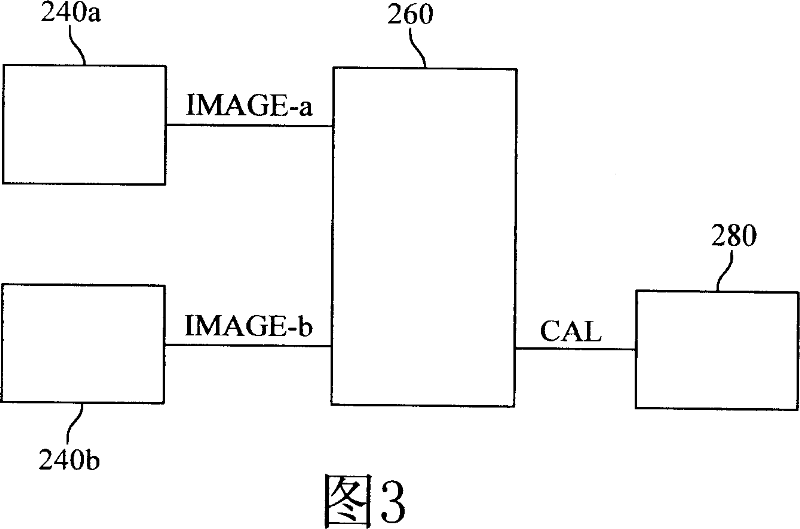

[0085] When performing the ACF process, the LCD panel is thermocompression bonded to the TCP IC using the automated thermocompressor according to the present invention. Firstly, the LCD panel is placed on the first carrying platform, and the TCP IC is placed on the second carrying platform, and the outer pins of the TCP IC face down and overlap the electrode connection end of the LCD panel. Then, the LCD panel and the TCP IC can be adsorbed and fixed on the carrying platform by using the suction airflow generated in the air holes on the carrying platform. Then, the two image-capturing devices respectively obtain the images on the left and right sides of the intersection from below through the corresponding mirror groups, and form two image signals accordingly. After the image signal is processed and analyzed by the image processing module, a correction signal can be obtained. The alignment device adjusts the position of the first carrying platform according to the correction ...

example 2

[0087] When performing the HSC process, the HSC is thermocompressively bonded to the TCP IC using the automated thermocompressor according to the present invention. All the procedures are roughly the same as above, except that when taking images, the two image taking devices directly obtain the images on the left and right sides of the overlap from above, and form two image signals based on them, so as to carry out alignment adjustment and heat pressing and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com