Air bearing

A technology of air bearings and supporting parts, applied in bearings, shafts and bearings, bearings for linear motion, etc., can solve the problems of inconvenient manufacturing of porous throttling air bearings and limited application range, and achieve vibration or shock attenuation If the time is too long, the structure is easy to process, and the effect of increasing processing difficulty and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

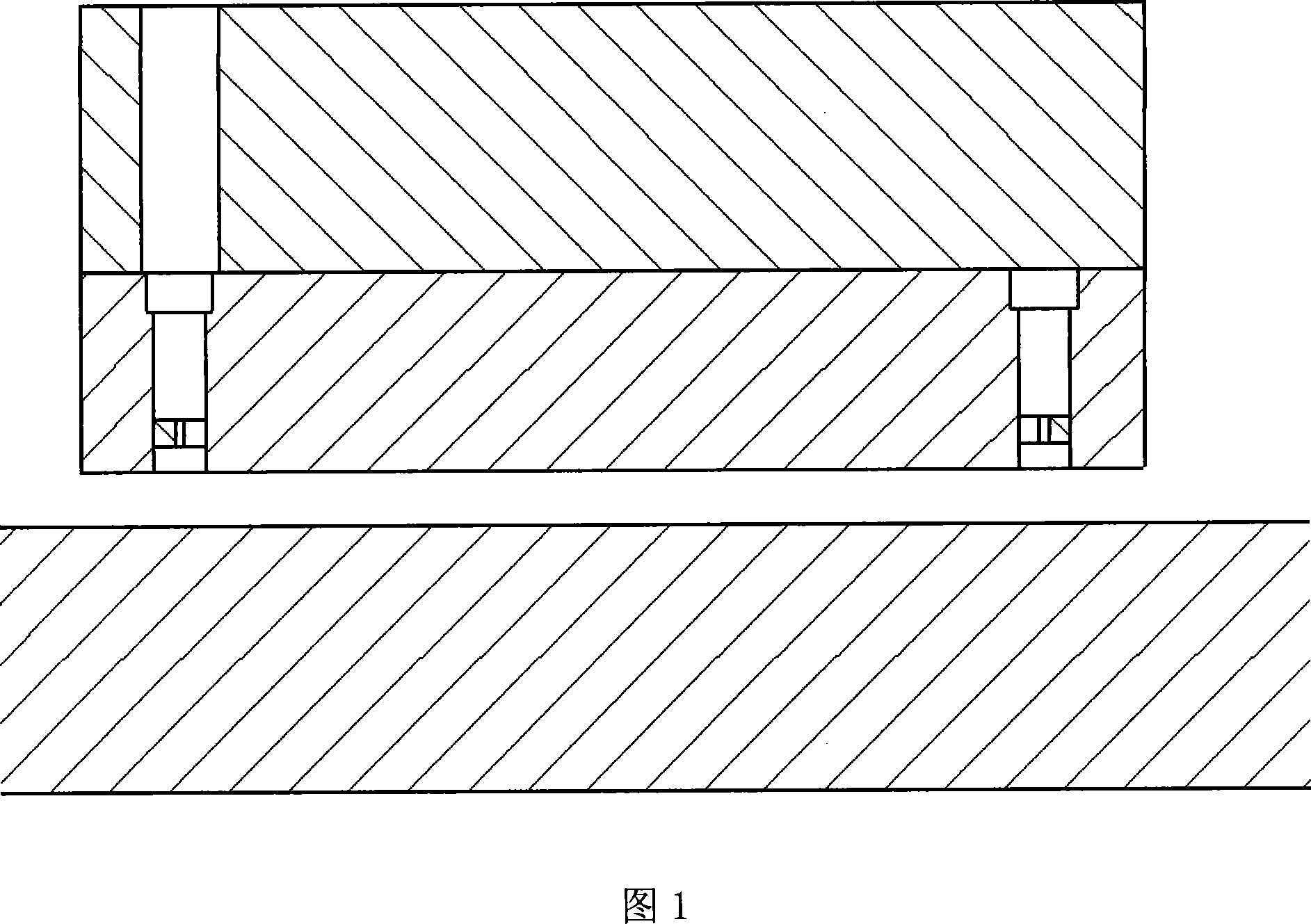

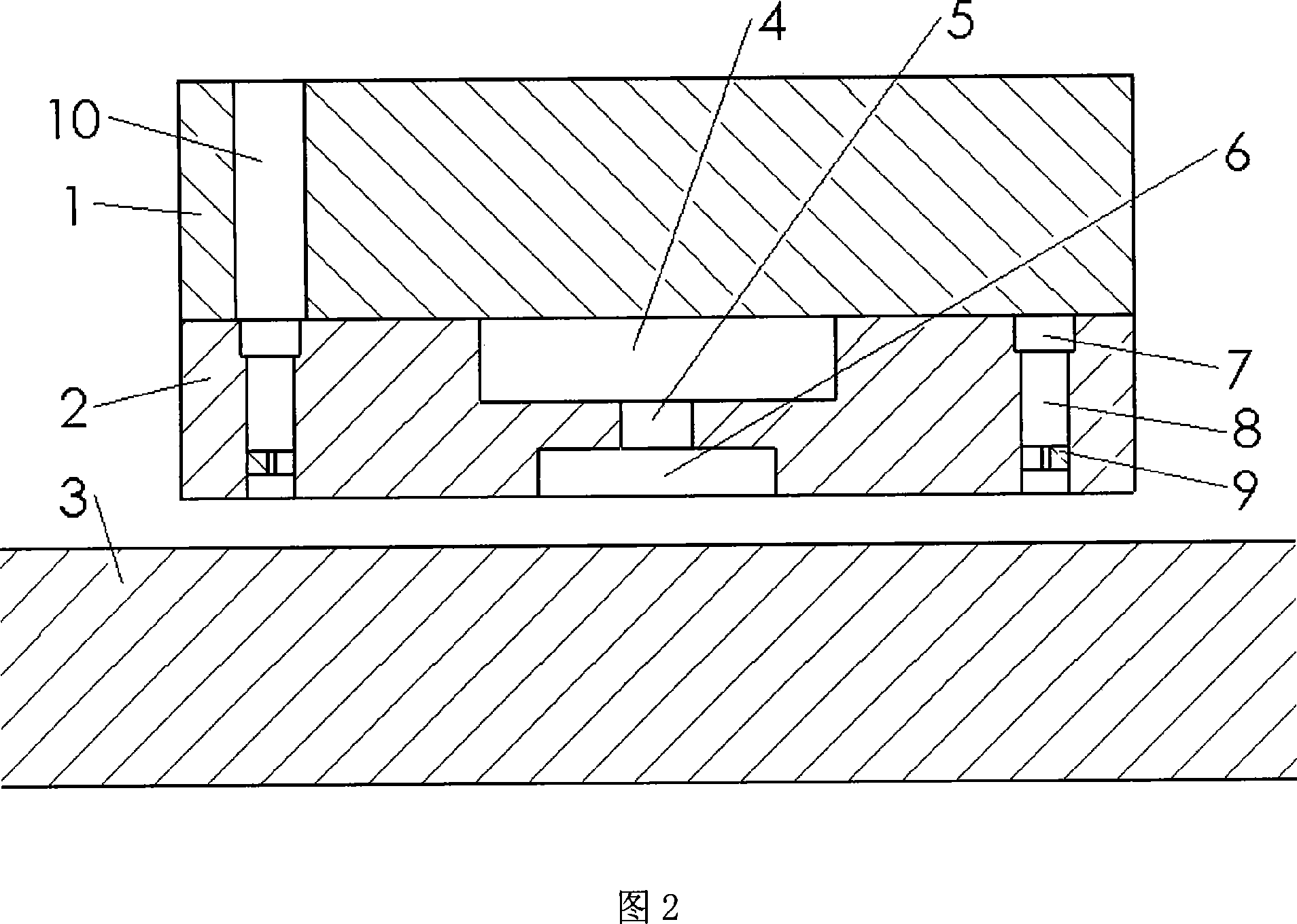

[0015] The working principle, structure and specific implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

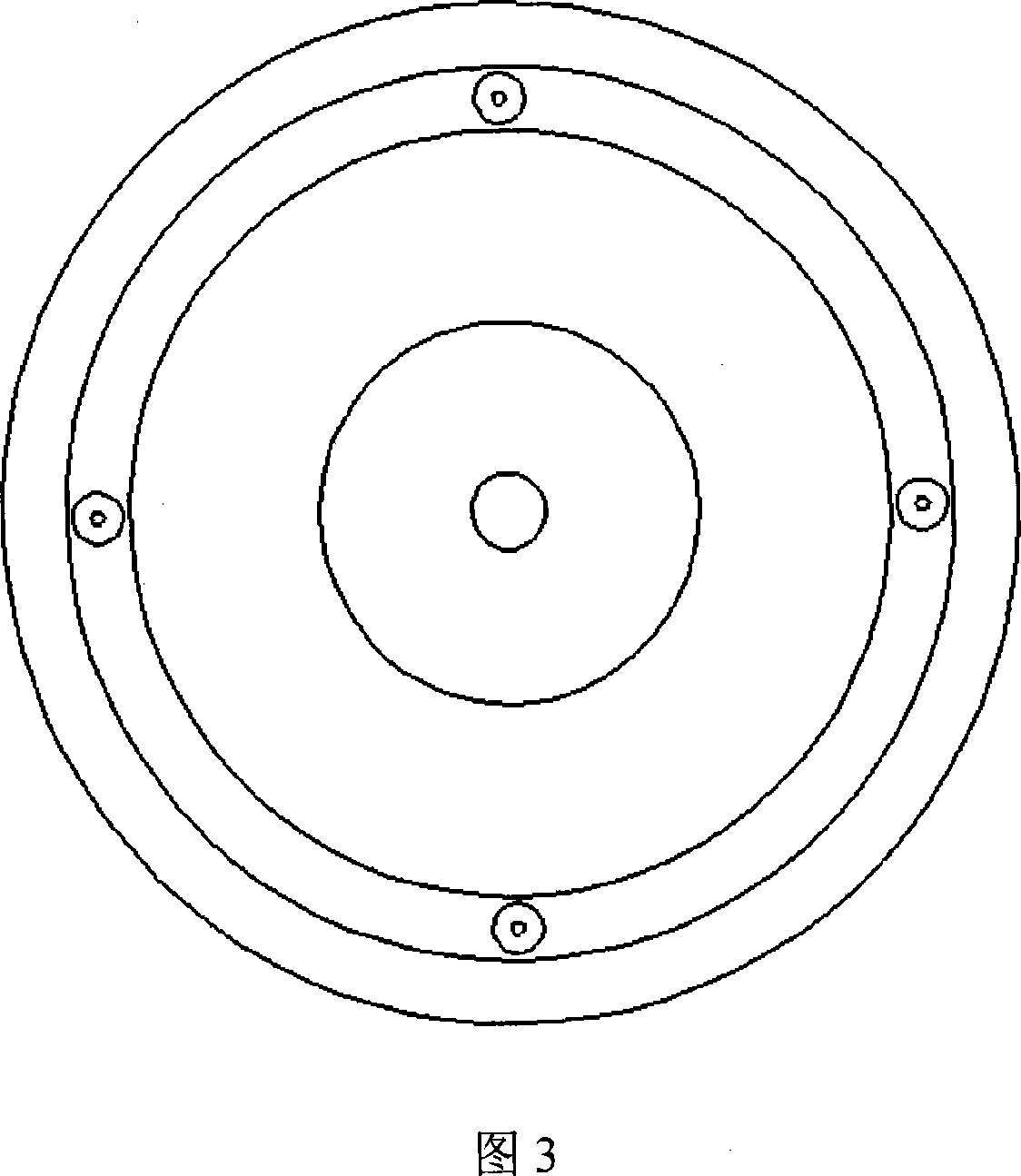

[0016] Fig. 2 is a schematic structural view of the air bearing provided by the present invention, the air bearing includes an air bearing body 2, an annular groove 7 and an orifice 8 communicating with the annular groove are arranged on the upper part of the air bearing body, and in the orifice A throttling plug 9 is arranged inside, an upper chamber 4 is arranged at the center of the upper part of the air bearing body 2 , a lower chamber 6 is arranged at the center of the lower part, and a damping hole 5 is arranged between the upper chamber 4 and the lower chamber 6 . The upper part of the air bearing body is fixedly connected with the lower part of the supported part, and there is an air gap between the lower part of the air bearing body and the bearing seat, forming a double-chamber structure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com