Rapid measuring method and apparatus for viscosity coefficient of dross

A rapid measurement and slag melting technology, applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of complex operation, high cost, long cycle, etc., and achieve the effect of simple measurement process, fast speed and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

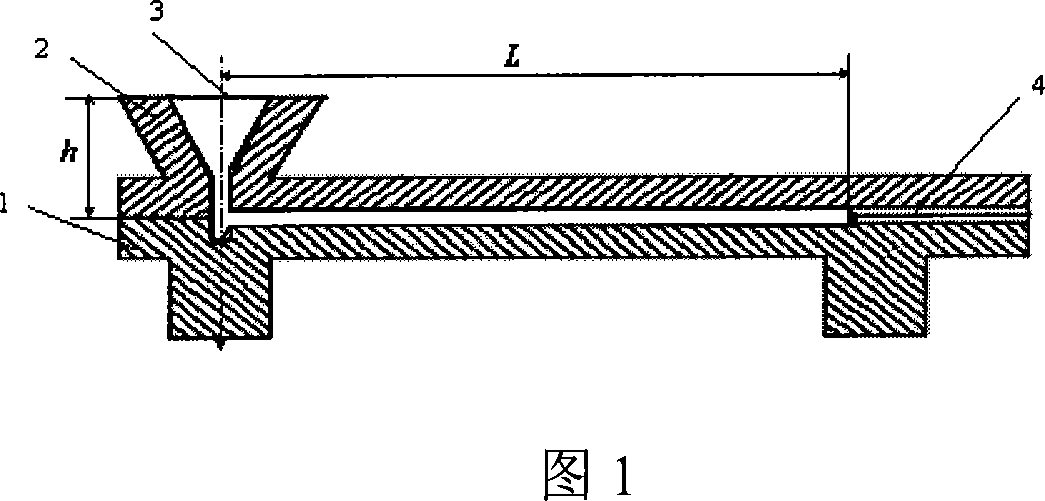

[0018] Referring to Fig. 1, the rapid assay device of the present invention is divided into two parts, a base 1 and a cover plate 2. The cover plate 1 includes a funnel 3 having a certain height h and half of a horizontal pipe 4, and the other half of the horizontal pipe 4 is located at the base. In the seat 1 , that is, the central cross-section passing through the center of the horizontal pipe 4 is located on the joint surface of the base 1 and the cover plate 2 . This structure is convenient for disassembly and assembly, and can conveniently pour out the cooled solid slag.

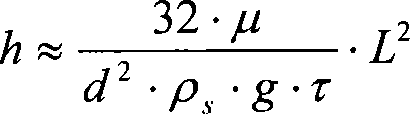

[0019] The working principle of the present invention is as follows: It can be seen from the principles of heat transfer and fluid mechanics that when the melt flows into a certain horizontal pipeline at a certain speed, the melt gradually solidifies due to heat dissipation, and the length of the flow path of the melt in the pipeline before solidification is It is related to many factors: from the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com