Method for measuring shearing bond strength between fibers

A combination of strength and fiber measurement technology, applied in paper testing, special data processing applications, instruments, etc., can solve the problems of time-consuming and labor-consuming measurement, difficult operation, complex instrument measurement, etc., to achieve good adaptability, easy implementation, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The slurry used in this embodiment is: bleached Canadian kraft pine pulp

[0034] The experimental instruments and equipment used include:

[0035] LabTech PFI Mill;

[0036] Standard Fiber Disperser;

[0037] Shaw beating degree meter;

[0038] LabTech transcriber;

[0039] Mesmer standard sheet press;

[0040] FS~200 fiber analyzer;

[0041] OLYMPUS microscope;

[0042] Lorentoen & Wettre tensile strength tester;

[0043] TechniBriten Miroo TB~1C whiteness meter;

[0044] PUCMAC Z~Span1000 zero-distance tensile strength tester;

[0045] The experimental process of this embodiment includes:

[0046] 1) Pulp preparation: Soak the pulp board in water for 12 hours, tear it up, sieve the pulp with a screener, keep the long fibers, and dehydrate for later use.

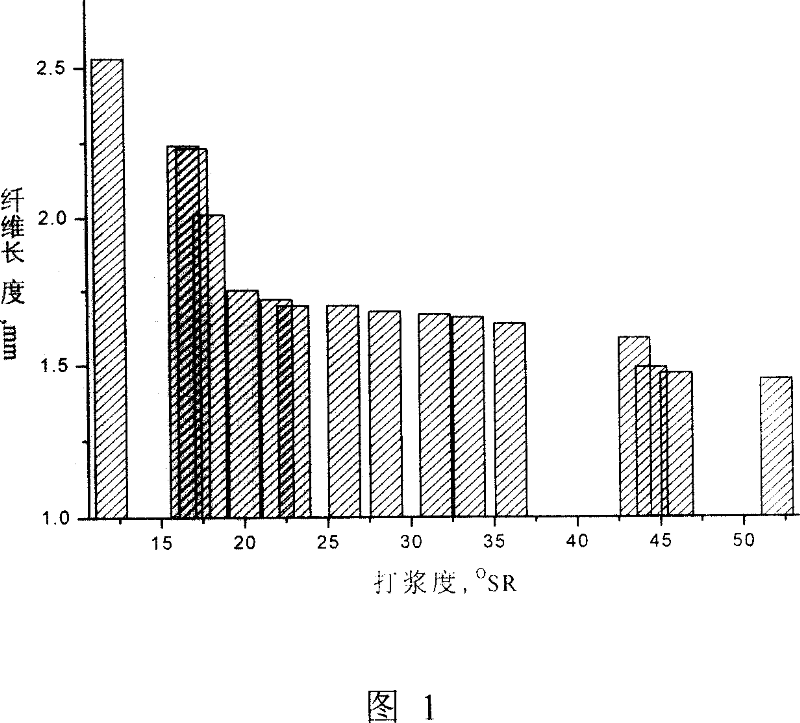

[0047] 2) Beating: Measure the water content, take 30g dry pulp, beat it with a PFI mill, measure the beating degree and fiber length L, circumference P, and thickness c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com