Shutter mechanism used in camera

A shutter and camera technology, applied in the shutter, camera, optics and other directions, can solve the problems of slow aperture change speed, shutter precision shutter speed change degree of freedom, change degree of freedom is small, etc., to achieve fast aperture switching speed and reduce assembly costs , switch effects with large degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

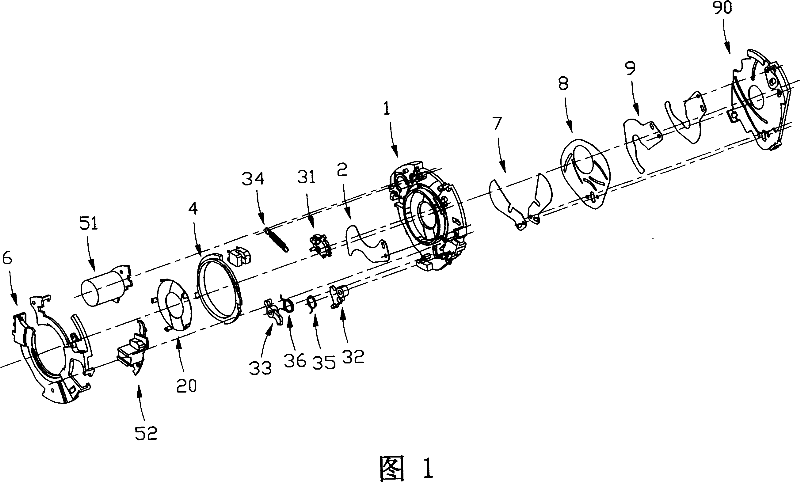

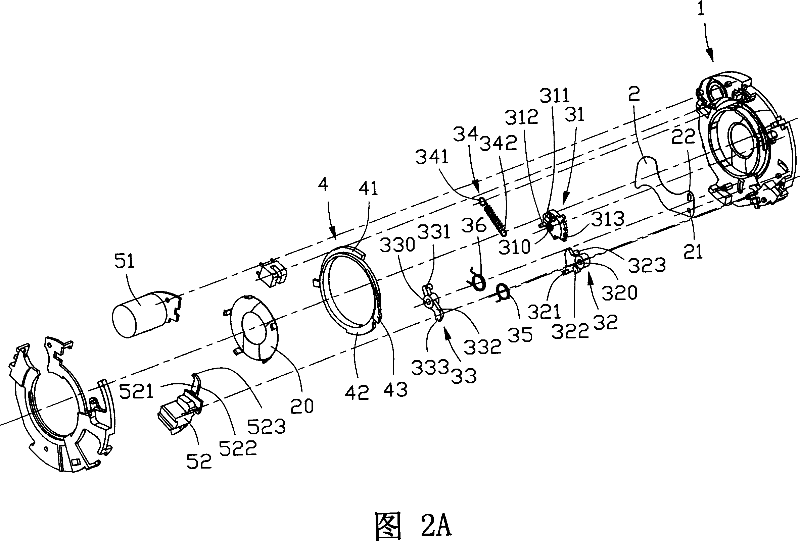

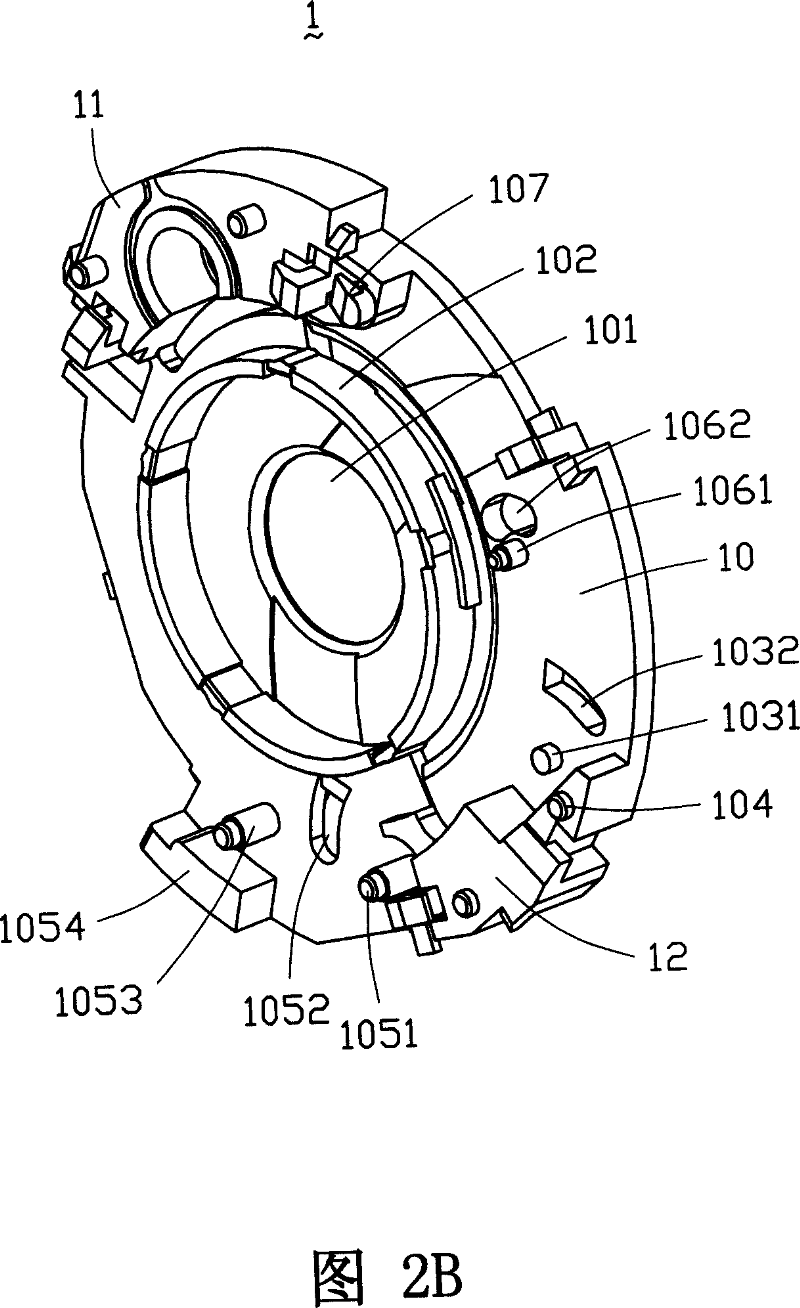

[0025] The shutter mechanism of the present invention includes a base 1, a light reducing mirror 2, a connecting rod device, a bore cam ring 4, a stepping motor 51, a solenoid valve motor 52, a connecting rod cover 6, a shutter feather 7, a feather partition 8, and a bore feather 9 and feather cover 90. The base 1 is generally in the shape of a disk, with a first surface 10 and a second surface 100 (see Fig. 2B and Fig. 3 ), and its middle part is provided with a central light hole 101 penetrating through the first and second surfaces, and the first surface 10 A motor seat 11 is provided at one side edge of the motor for receiving the stepper motor 51 . On the edge of the first surface 10 opposite to the motor seat 11 is a solenoid valve seat 12 , on which a solenoid valve support 104 is arranged for receiving and fixing the solenoid valve motor 52 . The first surface 10 is provided with a central ring wall 102 surrounding the central light hole 101 for arranging the aperture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com