A kind of sealing material for sensor and preparation method thereof

A sealing material and sensor technology, applied in chemical instruments and methods, other chemical processes, non-polymer adhesive additives, etc., can solve problems such as poor insulation, insulation resistance, decrease in bonding strength and stiffness, and sensor zero drift , to achieve the effects of excellent high temperature and high humidity resistance, excellent salt spray resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a sealing material for a sensor, said method comprising the following steps:

[0047] (1) Add 50g Al 2 o 3 Mix it with 100 g of alkoxy-terminated polydimethylsiloxane, and stir and defoam at 180° C. under a vacuum degree of -0.10 MPa for 2 hours to obtain the first mixture;

[0048] (2) Mix the first mixture obtained in step (1) with 15 g of a cross-linking agent, and stir and defoam at 30° C. under a vacuum degree of -0.10 MPa for 10 minutes to obtain a second mixture;

[0049] (3) Mix the second mixture obtained in step (2) with 5g of γ-(2,3-glycidoxy)propyltrimethoxysilane and 5g of catalyst, and stir and defoam at 30°C under vacuum degree -0.10MPa for 30min Obtain the sealing material.

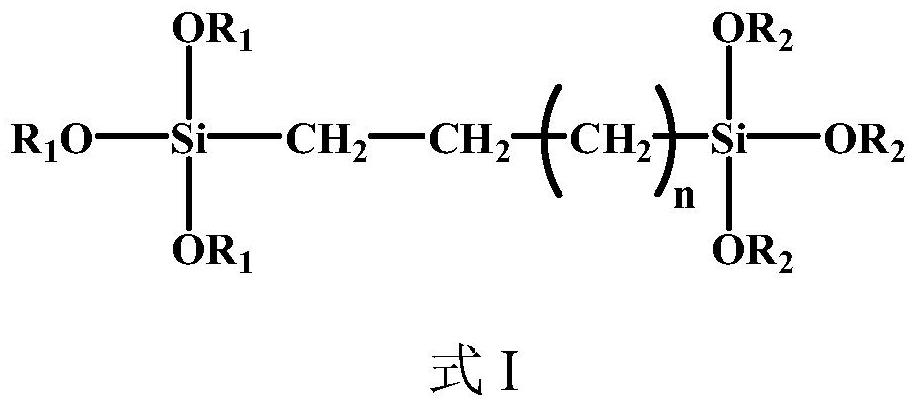

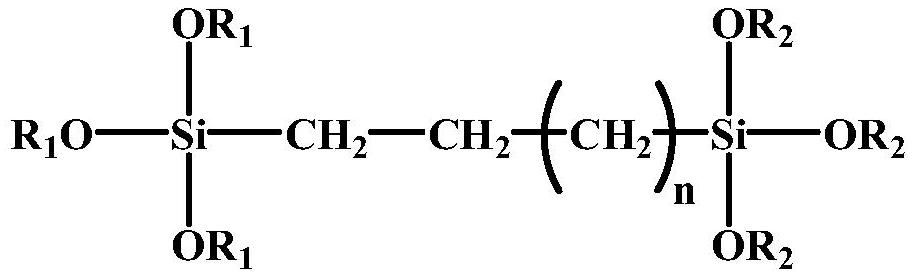

[0050] Wherein, the structural formula of cross-linking agent is (CH 3 O) 3 SiCH 2 CH 2 Si(CH 3 O) 3 , the structural formula of the catalyst is Ti[(OSi(CH 3 ) 2 ) 1000 OSi(CH 3 ) 3 ] 4 .

Embodiment 2

[0052] A method for preparing a sealing material for a sensor, said method comprising the following steps:

[0053] (1) 100g SiO 2 Mix it with 50 g of alkoxy-terminated polydimethylsiloxane, stir and defoam at 105° C. under a vacuum of -0.08 MPa for 6 hours to obtain the first mixture;

[0054] (2) Mix the first mixture obtained in step (1) with 5 g of cross-linking agent, and stir and defoam at 10° C. under a vacuum degree of -0.08 MPa for 30 minutes to obtain the second mixture;

[0055] (3) The second mixture obtained in step (2) was mixed with 0.1 g of γ-aminopropyltrimethoxysilane and 0.1 g of catalyst, stirred and degassed at 10° C. for 90 minutes under a vacuum degree of -0.08 MPa to obtain the sealing material.

[0056] Wherein, the structural formula of cross-linking agent is (CH 3 CH 2 O) 3 SiCH 2 CH 2 CH 2 Si(OCH 2 CH 3 ) 3 , the structural formula of the catalyst is Ti[O(C 3 h 6 O) 50 (C 2 h 4 O) 50 H][(OSi(CH 3 ) 2 ) 50 OSi(CH 3 ) 3 ] 3 .

Embodiment 3

[0058] A method for preparing a sealing material for a sensor, said method comprising the following steps:

[0059] (1) 60g SiO 2 Mix it with 90g of alkoxy-terminated polydimethylsiloxane, stir and defoam at 150°C under a vacuum of -0.09MPa for 4h to obtain the first mixture;

[0060] (2) Mix the first mixture obtained in step (1) with 10 g of cross-linking agent, and stir and defoam at 20° C. under a vacuum degree of -0.09 MPa for 20 minutes to obtain the second mixture;

[0061] (3) The second mixture obtained in step (2) was mixed with 2 g of γ-aminopropyltrimethoxysilane and 2 g of catalyst, and stirred and degassed at 20° C. for 60 minutes under a vacuum degree of -0.09 MPa to obtain the sealing material.

[0062] Wherein, the structural formula of cross-linking agent is (CH 3 O) 3 SiCH 2 CH 2 CH 2 CH 2 Si(OCH 2 CH 3 ) 3 , the structural formula of the catalyst is Ti[O(C 3 h 6 O) 200 (C 2 h 4 O) 200 H] 2 [(OSi(CH 3 ) 2 ) 500 OSi(CH 3 ) 3 ] 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com