Abrasive cloth and producing method thereof

A manufacturing method and technology of abrasive cloth, which is applied in the direction of manufacturing tools, abrasives, metal processing equipment, etc., can solve the problems of not being able to polish curved surfaces or water chestnuts, not being able to fit polished products well, wasting abrasive grains and resin, etc., to achieve Low manufacturing cost, high speed, and the effect of saving abrasive grains and resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

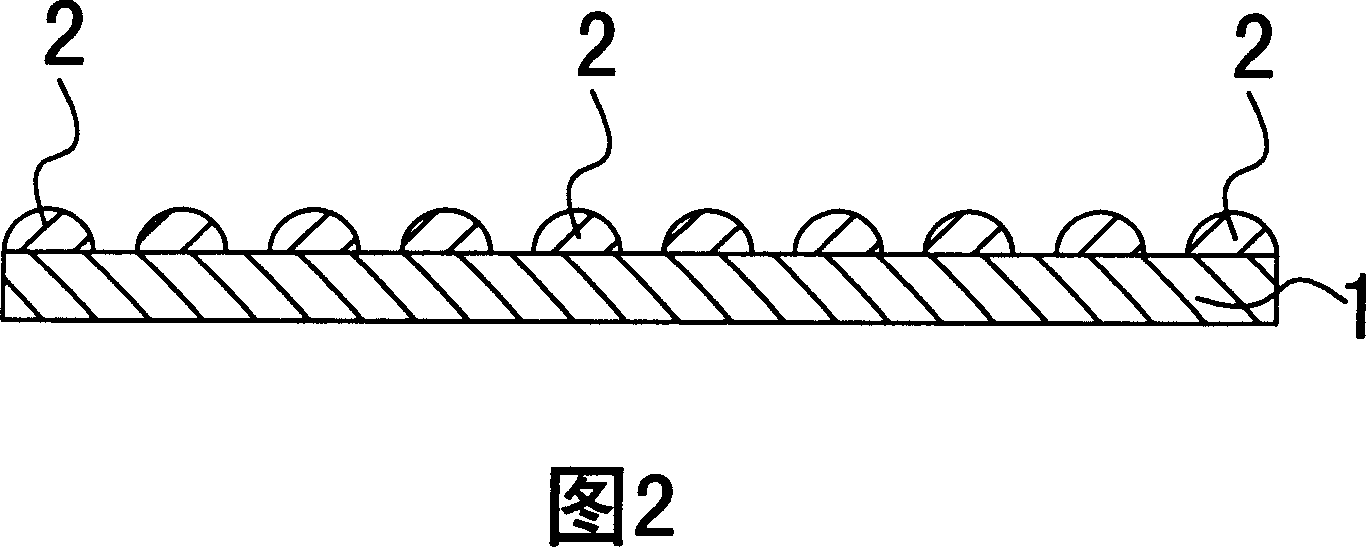

[0033] A kind of emery cloth, as shown in Figure 2, comprises a piece of flexible base 1 and several grinding grains 2, and flexible base 1 has a front, and grinding grain 2 is all independently directly fixed on the front of flexible base 1, and each grain The abrasive particles have the same structure. The flexible base layer 1 can be cloth or paper.

[0034] Abrasive grains 2 are a mixture of abrasive grains and resin. The size of the abrasive grains is between 0.5 and 1000 microns, preferably between 1 and 100 microns, wherein the smaller the size of the abrasive grains, the better the surface finish of the ground product. In this embodiment Among them, diamonds are used as abrasive grains, but the present invention is not limited to diamonds, and others such as fused alumina, heat-treated alumina, silicon carbide, alumina-zirconia, garnet, cubic boron nitride, or a mixture of the above , is also applicable to the present invention. Resin is preferably the resin that ca...

Embodiment 2

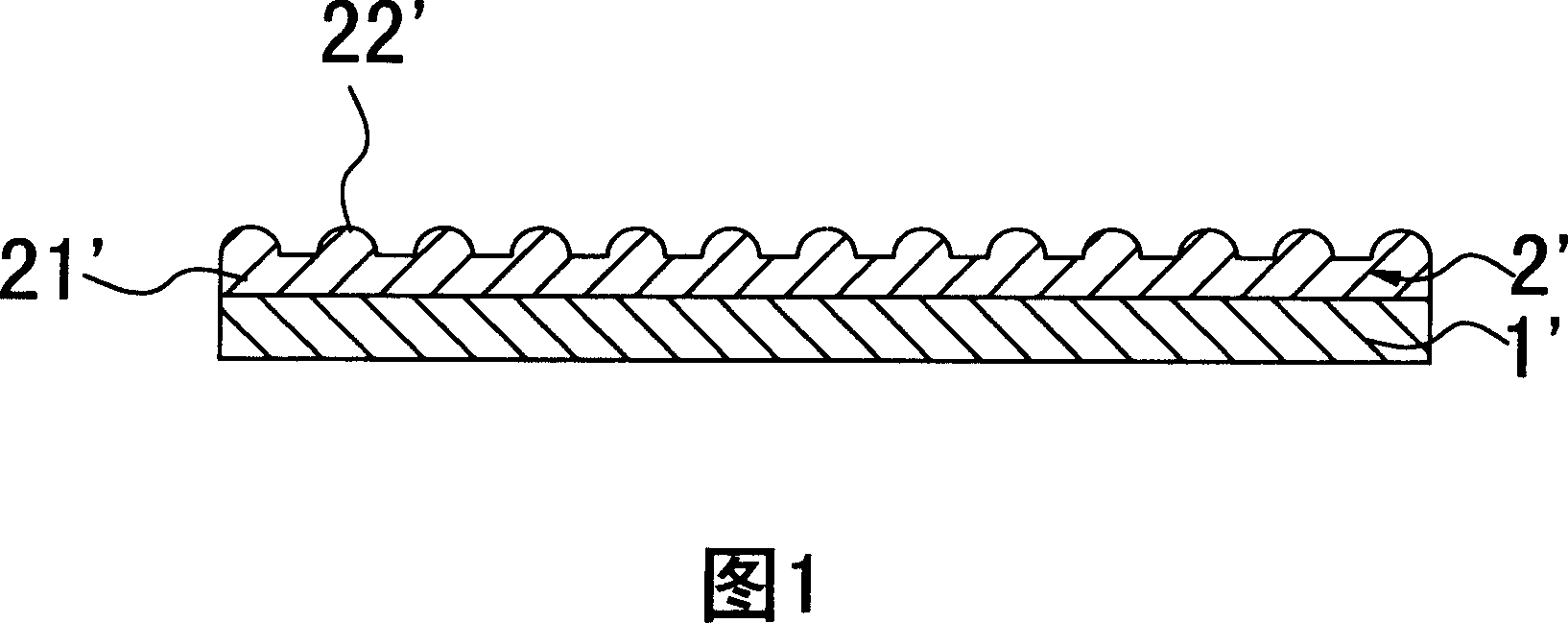

[0039] This embodiment introduces a manufacturing method that can manufacture the above-mentioned emery cloth. Another matching mold has a parting surface on the mold, and a plurality of independent cavities are opened on the parting surface. The number and arrangement of the cavities are respectively the same as the number and arrangement of the grinding particles 2 of the gauze. The same, and the shape of the concave cavity is the same as the shape of the grinding particle 2, which is also a hemispherical shape, and its diameter is between 1 and 5 mm. Wherein, the mold material can be flexible plastic or rubber, such as polypropylene.

[0040] A method for manufacturing emery cloth, the method comprising:

[0041] (1). The first step: All the cavities of the mold are filled with a mixture slurry of liquid grinding particles 2, which is also a slurry of a mixture of abrasive particles and resin, wherein the mass ratio of abrasive particles to resin is 1 : 1, preferably a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com