Sacrificial anode or cathod protected automatic detecting and treating system

A cathodic protection and automatic detection technology, applied in the field of sacrificial anode cathodic protection automatic detection and processing system, can solve the problems of long data detection time interval, detection data can only be recorded and processed manually, and the processing level of protection system is stagnant. The effect of ensuring uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

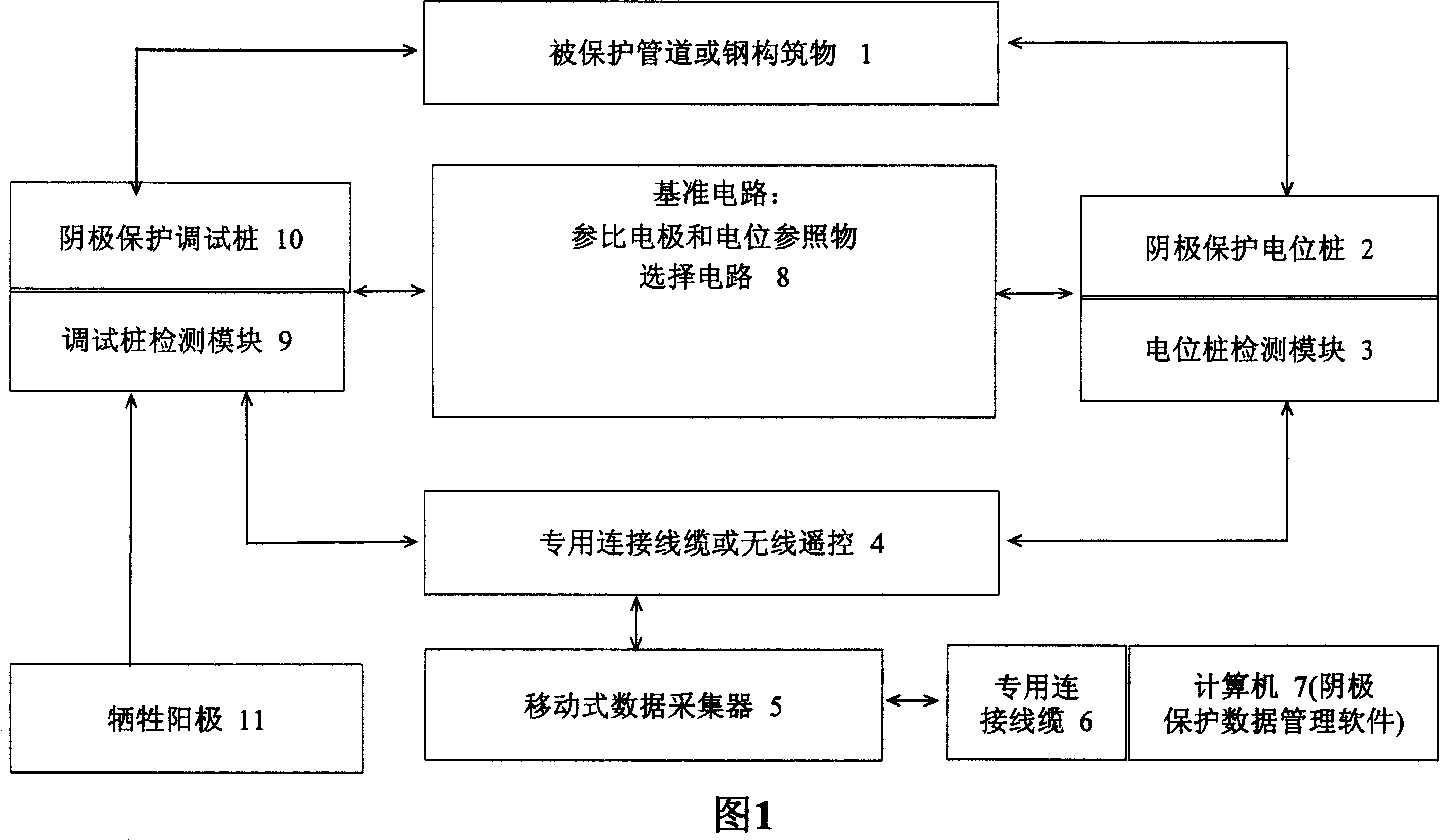

[0047] Please refer to Fig. 1, the sacrificial anode cathodic protection automatic detection and processing system of the present invention includes cathodic protection debugging pile 10, cathodic protection debugging pile detection module 9, cathodic protection potential pile 2, cathodic protection potential pile detection module 3, mobile data acquisition Device 5, reference circuit 8, computer 7,

[0048] The cathodic protection debugging pile detection module 9 is installed in the cathodic protection debugging pile 10, one end is connected to the sacrificial anode 11, and the other end is connected to the protected pipeline or steel structure 1, and the detection module 9 is connected through a special connection cable or a wireless remote control 4 To the mobile data collector 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com