Process of measuring carbonyl compound content in oil and grease

A standard substance, isopropanol technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of long time, cumbersome operation, large amount of solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

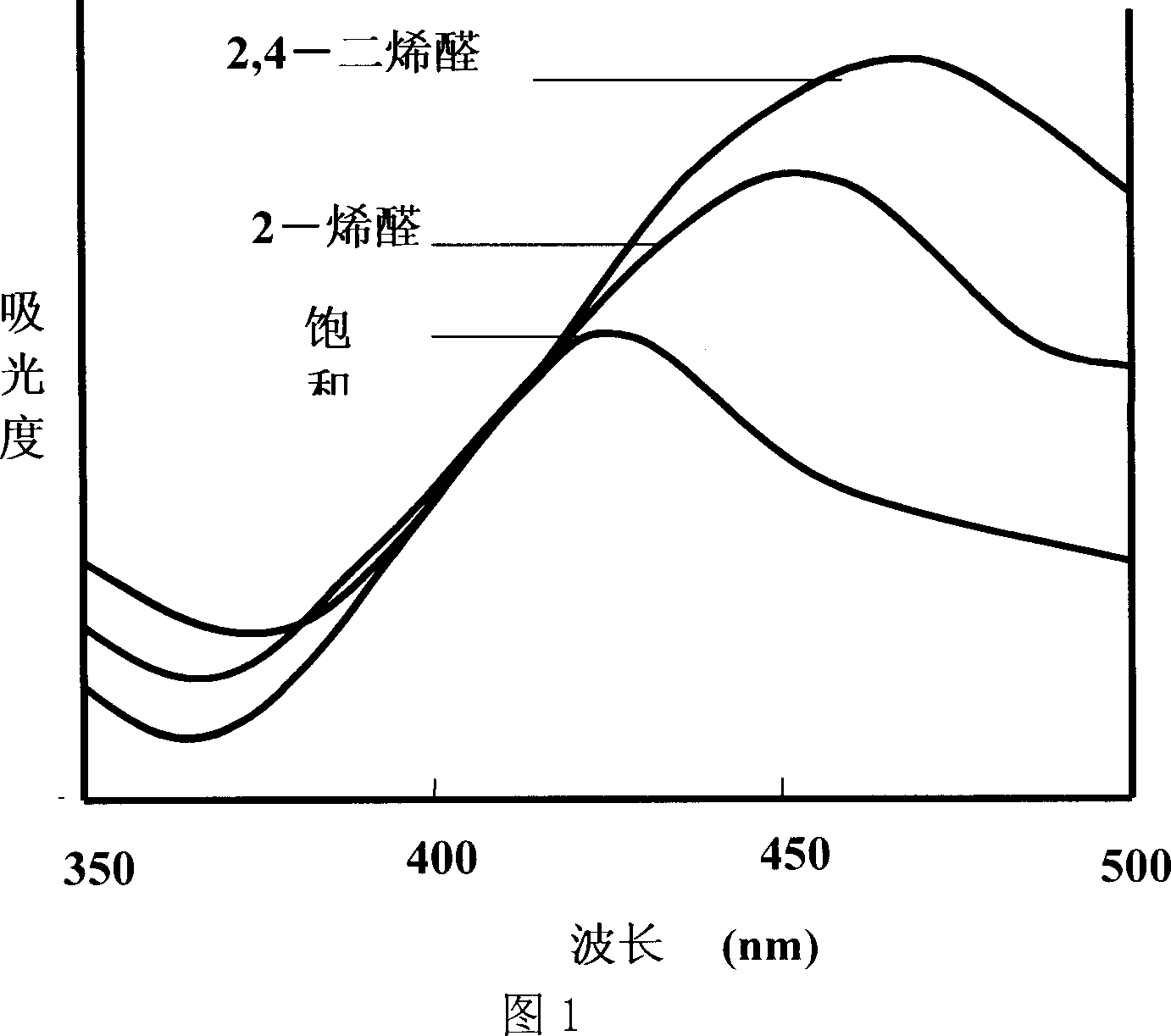

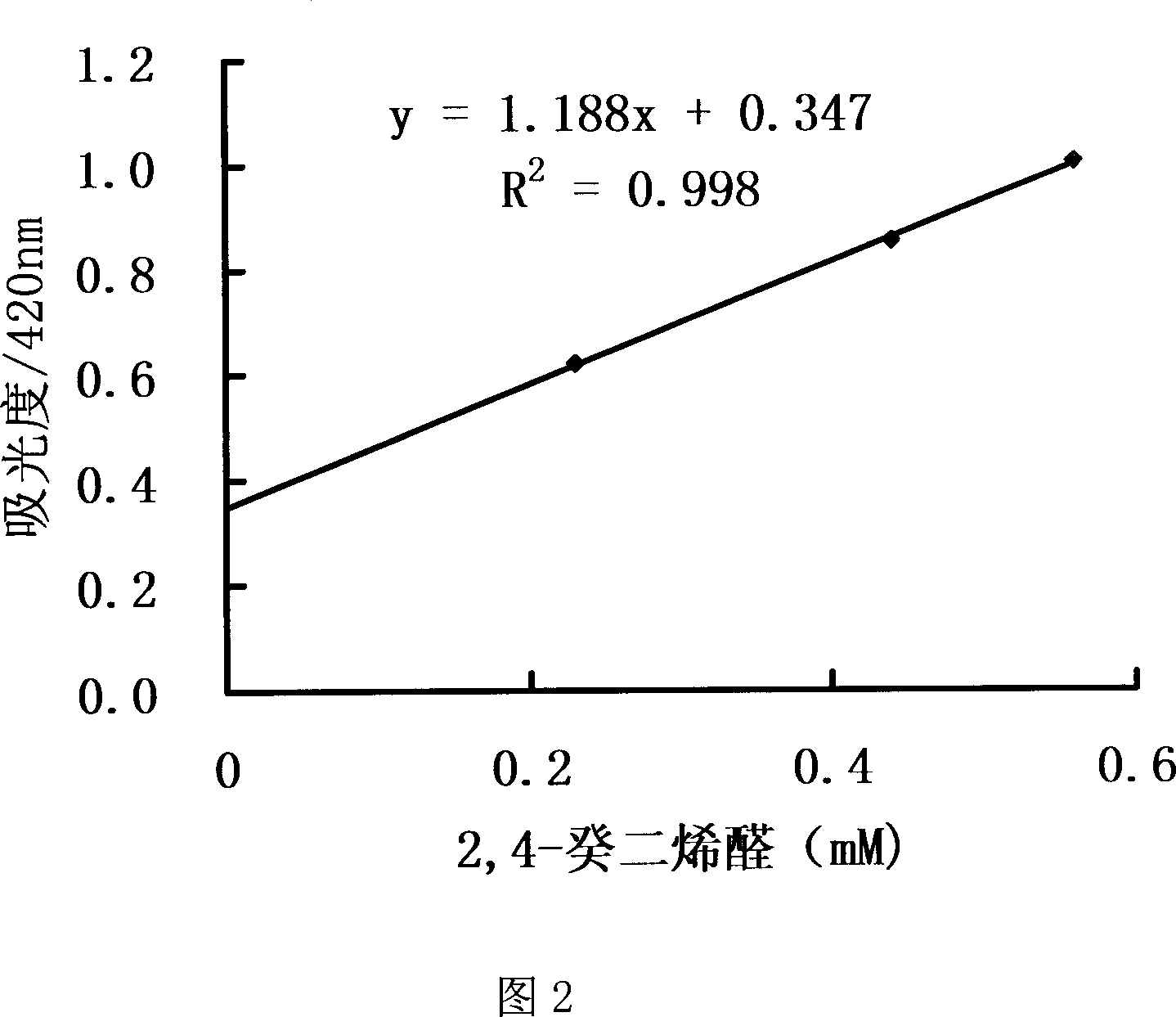

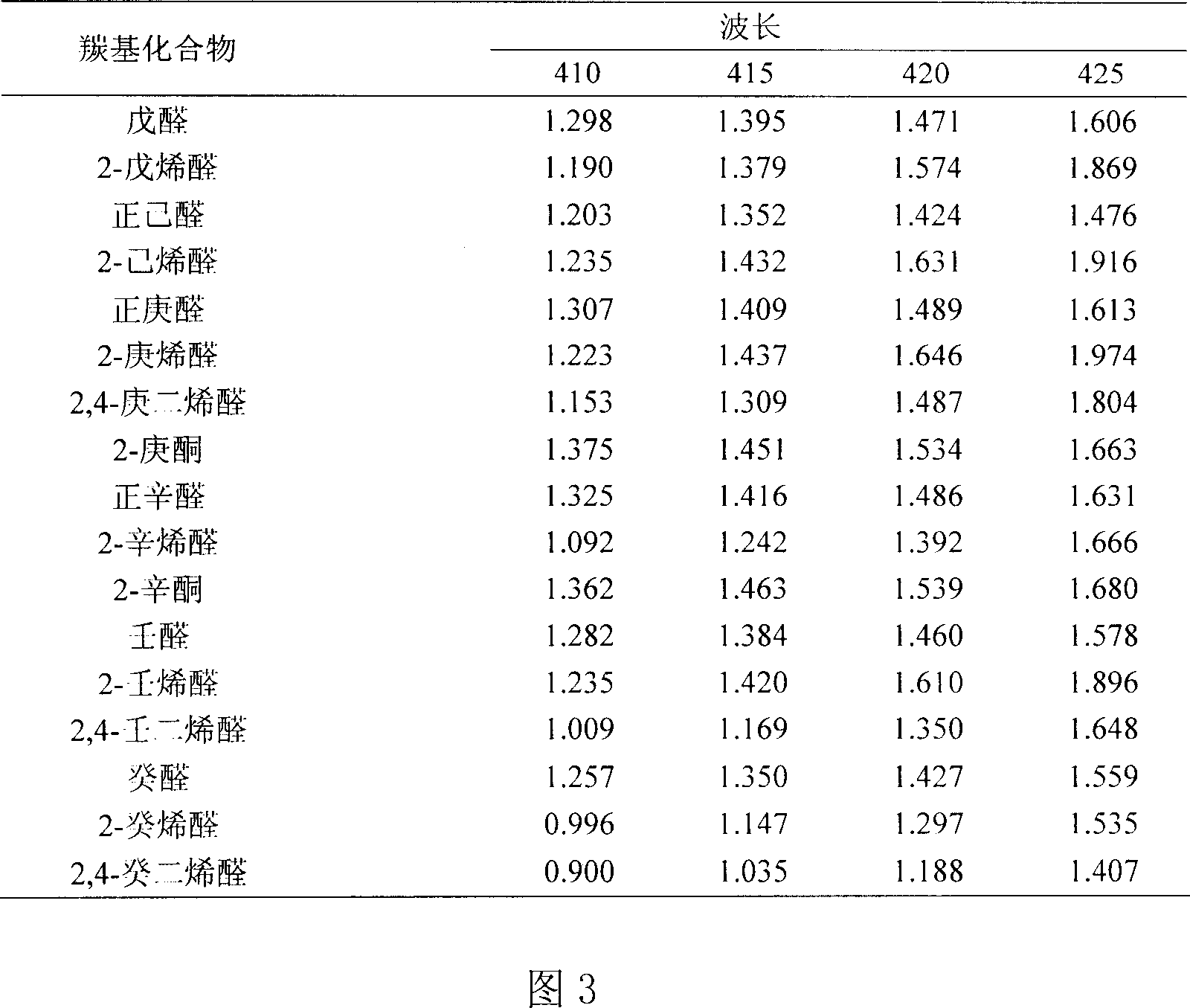

[0008] Weigh 0.04 to 1.0 g of the oil sample and put it into a 10 ml volumetric flask, and dilute to volume with isopropanol (or n-butanol) solution. Extract 1mL sample solution into a 15ml centrifuge tube, add 1ml 2,4-dinitrophenylhydrazine solution (3.5% HCL), cover with a stopper, shake well, and heat in a water bath at 40°C for 20min. After the reaction, it was taken out and cooled to room temperature with running water, and 8 ml of 4% KOH isopropanol solution was added to develop the color. The test tube was centrifuged at 3000 rpm / min for 5 min, and the supernatant was taken to measure its absorbance at 410-425 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com