Solid electrolyte fuel cell and process for the production thereof

A technology of solid electrolyte and solid electrolyte layer, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve problems such as adhesion damage, and achieve the effect of improving power supply and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] (1) Preparation of solid electrolyte fuel cell

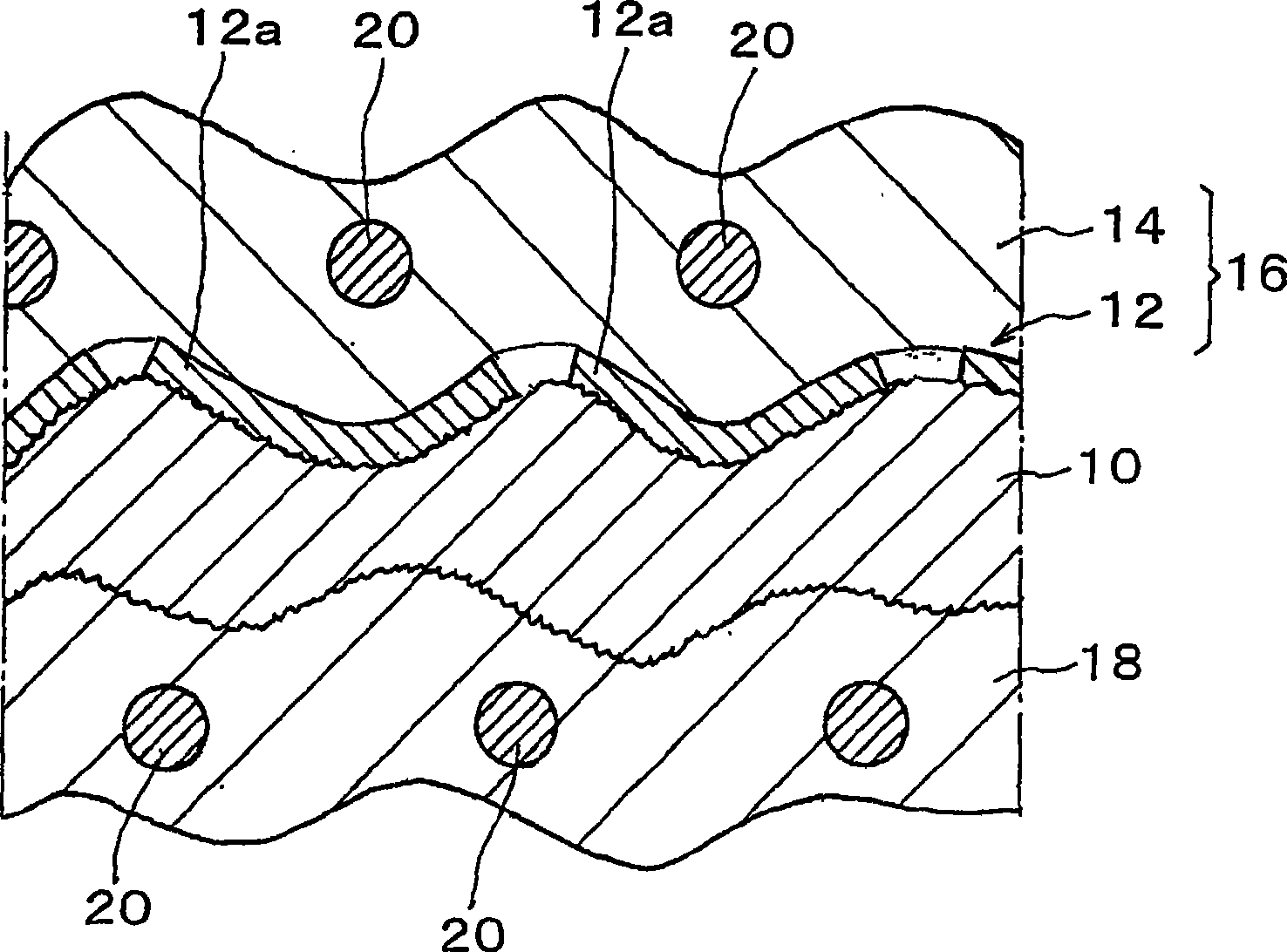

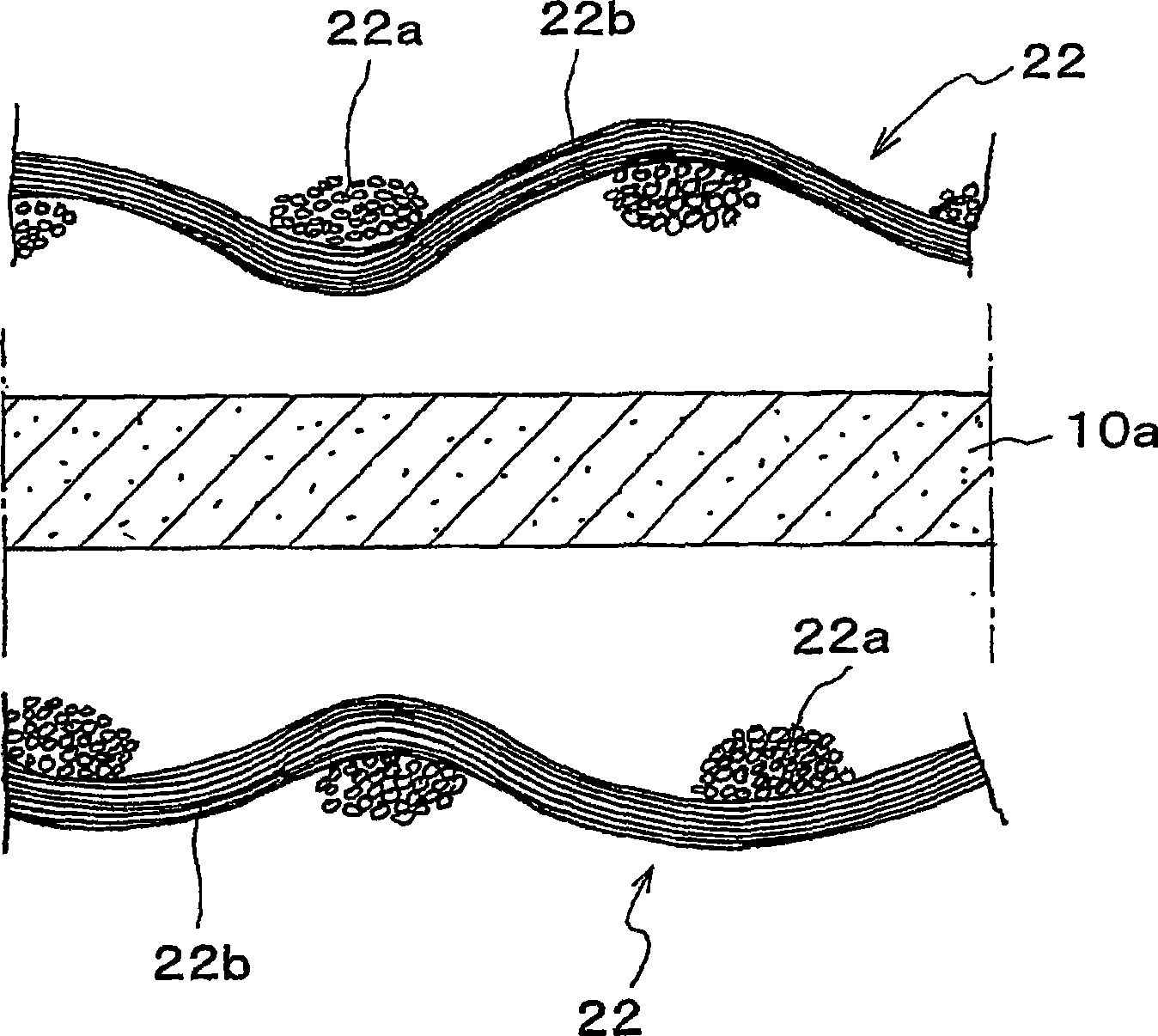

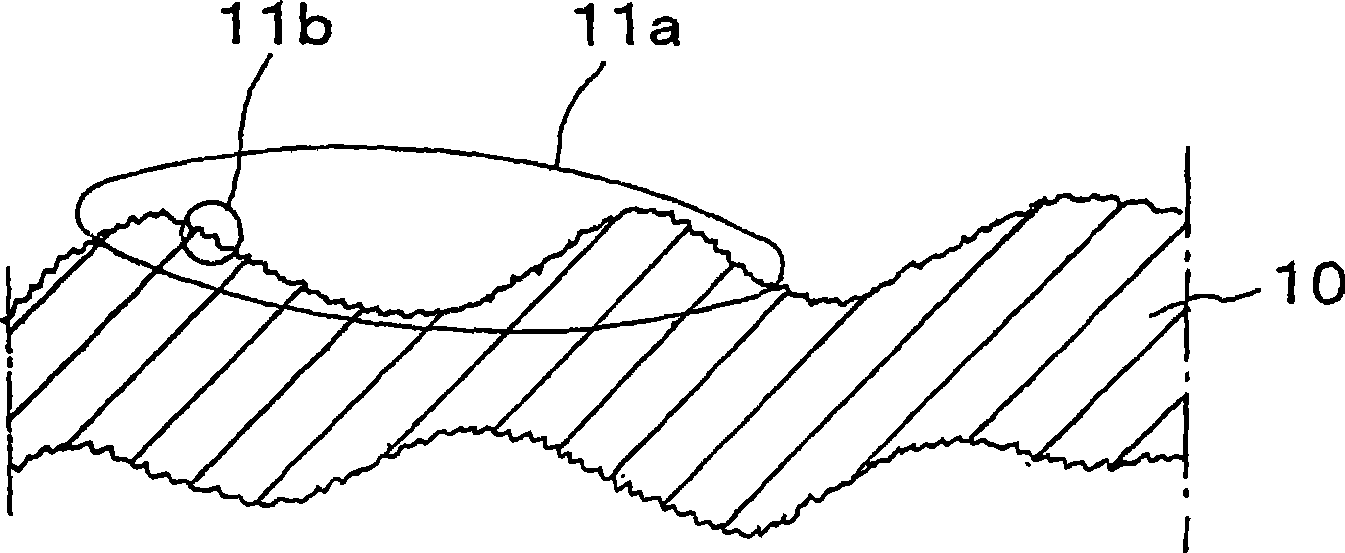

[0101] In order to prepare the solid electrolyte layer 10, a pressure of 150 kg / cm is used 2 The hydraulic press of ”uses the doctor blade method to press the plain weave fabric 22, 22 to both sides of the solid electrolyte green sheet. The fabrics 22, 22 are then peeled off from both sides of the green sheet. Then, both sides of the solid electrolyte green sheet thus peeled off were observed. As a result, it was found that a periodic checkerboard-shaped first roughened portion was formed. It was also found that the first roughened portion has a second roughened portion with a short period formed on the single fiber constituting the fabric 22, 22 formed thereon.

[0102] The solid electrolyte green sheet was punched into a circular shape, and then calcined at 1,300°C to obtain a Sm 0.2 Ce 0.8 O 1.9 (Samarium oxide doped ceria: SDC) made of ceramic substrate, its thickness is 180μm, diameter φ is 15mm.

[0103] Then put the pa...

Embodiment 2

[0124] (1) Preparation of solid electrolyte fuel cell

[0125] In order to prepare the solid electrolyte layer 10, a pressure of 150 kg / cm is used 2 The hydraulic press of ”uses the doctor blade method to press the plain weave fabric 22, 22 to both sides of the solid electrolyte green sheet. The fabrics 22, 22 are then peeled off from both sides of the green sheet. Then, both sides of the solid electrolyte green sheet thus peeled off were observed. As a result, it was found that a periodic checkerboard-shaped first roughened portion was formed. It was also found that the first roughened portion has a second roughened portion with a short period formed on the single fiber constituting the fabric 22, 22 formed thereon.

[0126] The solid electrolyte green sheet was punched into a circular shape, and then calcined at 1,300°C to obtain a Sm 0.2 Ce 0.8 O 1.9 (Samarium oxide doped ceria: SDC) made of ceramic substrate, its thickness is 180μm, diameter φ is 15mm.

[0127] Then put the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com