Battery leakage detection system

A leak detection and battery technology, applied in battery/battery leak testing, secondary battery, secondary battery repair/maintenance, etc., can solve problems such as high power, achieve low energy consumption, simple electrical signal conversion, and fast manufacturing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

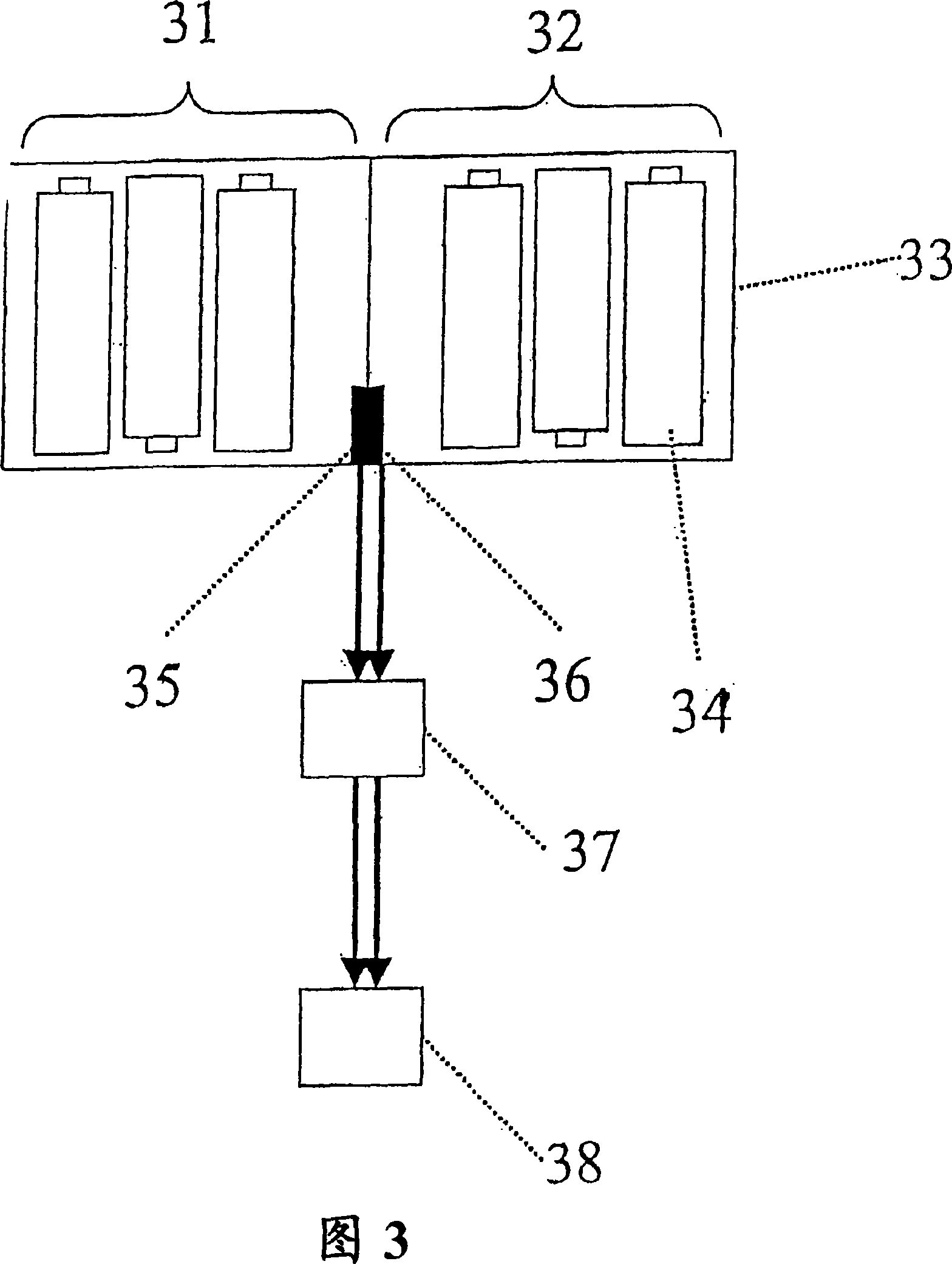

[0040] Figures 1-3 illustrate how to use a gas store in a battery pack or a battery pack. These examples preferably relate to the application of the invention for monitoring batteries in electronic products.

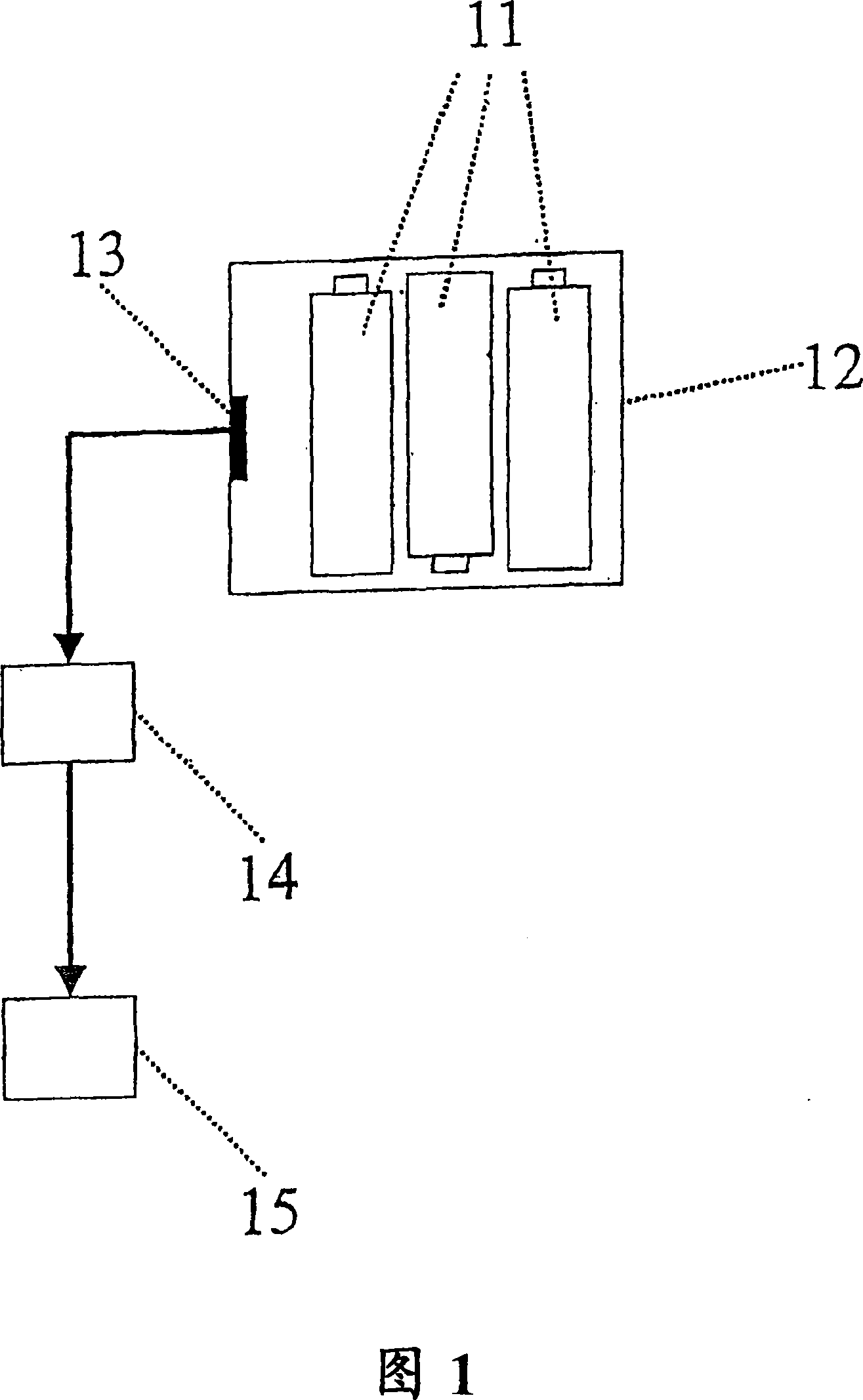

[0041]Fig. 1 is a layout diagram of the first embodiment. The gas sensor 13 is installed in the battery case 12 or a battery pack. As soon as the battery 11 begins to leak chemicals, the volatile species diffuses to the location of the sensor 13 and triggers a sensor signal 14 . This signal is used by the safety management system 15 to provide, for example, a message to the product user and / or initiate a safe shutdown operation. The safety management system 15 may utilize an intranet or Internet connection to remotely send or receive sensor signals or provide information regarding battery status. In order to minimize air circulation within the battery compartment 12 to ensure reliable detection of a leaking battery 11, the battery housing 12 is preferably closed or ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com