Cantalever type processing robot with fire and water

A robot and cantilever-type technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of low utilization efficiency of large equipment, insufficient processing space, and insufficient mechanism flexibility, etc., to achieve increased movement flexibility, simple structure, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

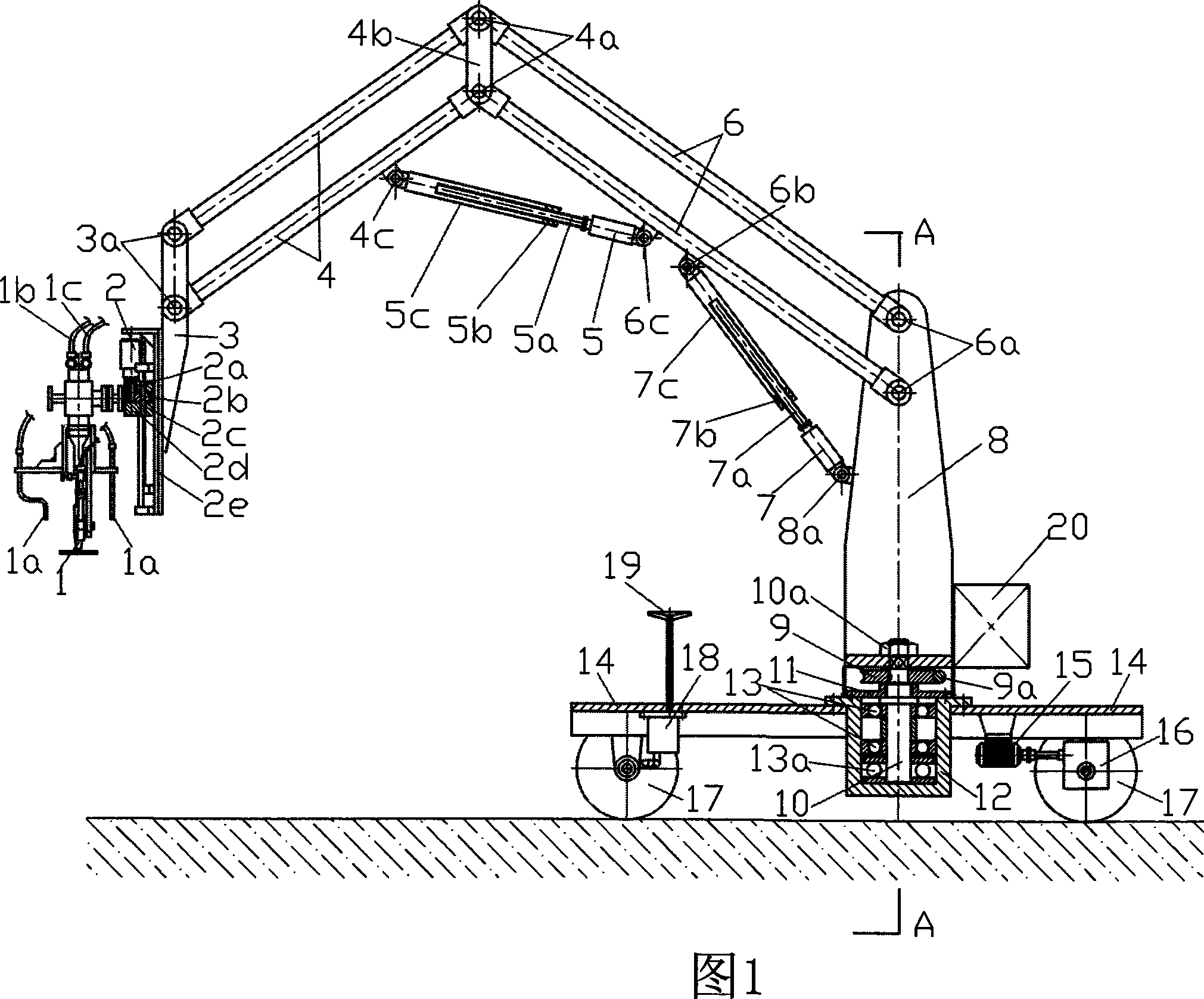

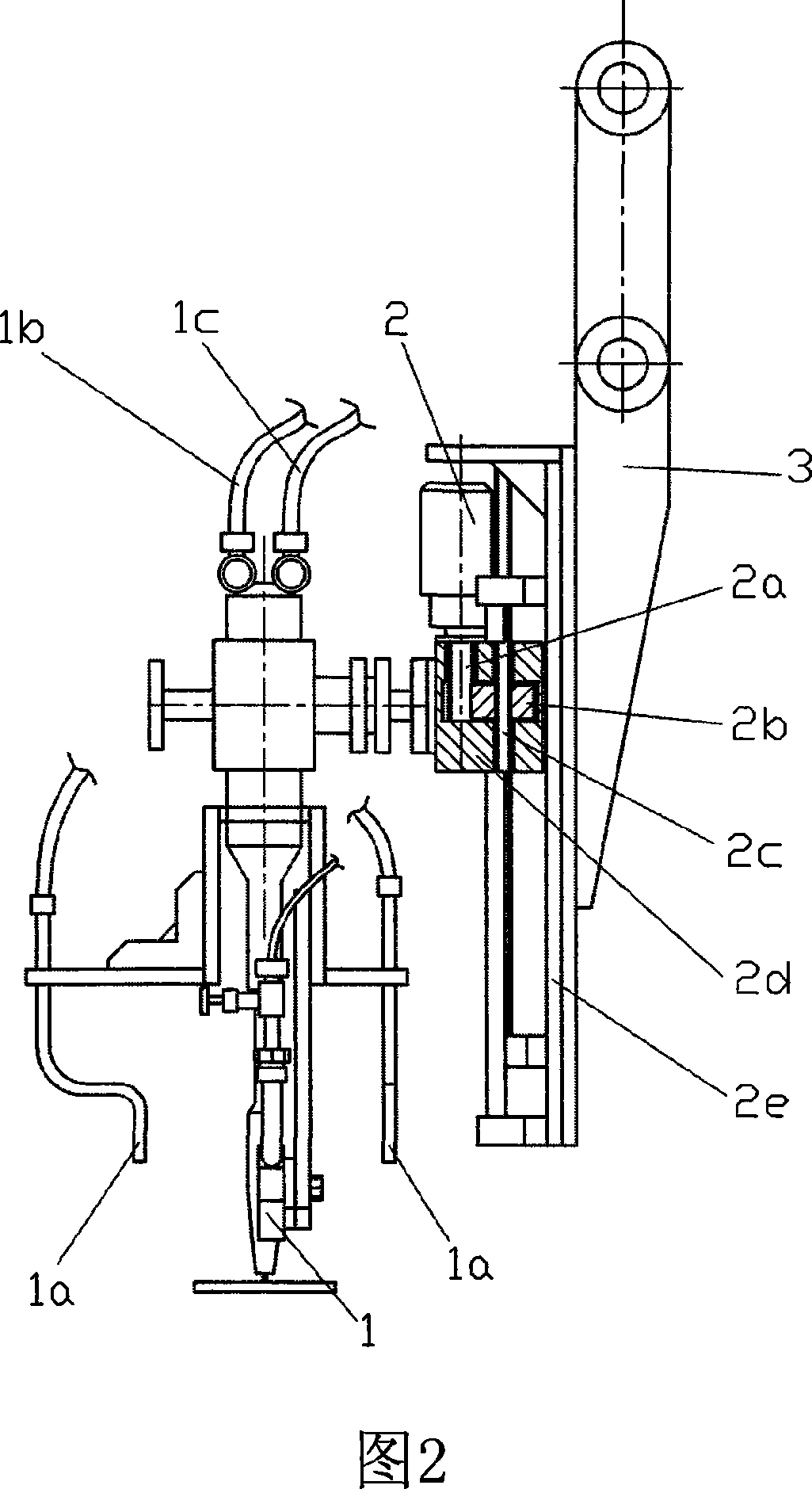

[0016] In the embodiment shown in Fig. 1, 2, 3, the chassis 14 of cantilever type water-fire processing robot adopts four-wheel type moving mechanism, drives two wheels 17 to move through a differential 16 with second motor 15, uses steering wheel 19 Drive the other two wheels 17 to turn through steering gear 18. The second motor 15 is a direct current motor and adopts a storage battery as a power supply.

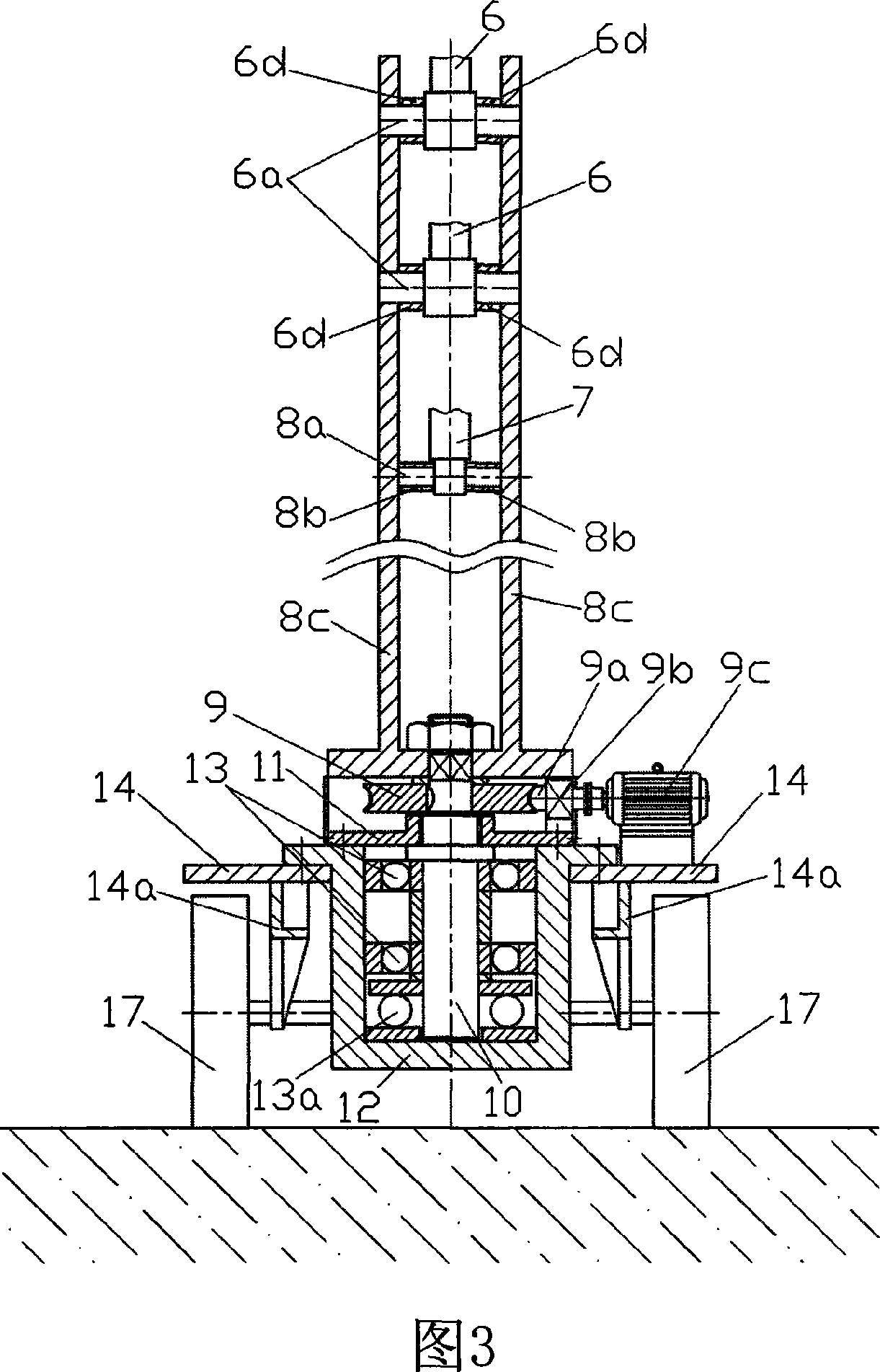

[0017] A bearing block 12 is fixed on the chassis 14 . The lower end of the rotating shaft 10 is provided with two radial ball bearings 13 and an axial thrust ball bearing 13a and installed in the bearing housing 12, and the inner rings of the three bearings are provided with spacers and closed with a gland 11; the rotating shaft 10 The upper end is provided with a large worm wheel 9 driven by a large worm 9a, and is fastened together with the turret 8 with a nut 10a.

[0018] The bottom of the turret 8 is provided with an electric control box 20, and the top is hingedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com